A new method of synthesizing ceramic composite materials based on Ti3SiC2 using non-powder reaction compositions of titanium and silicon carbide was developed. Aceramic composite with a Ti3SiC2–TiSi2 matrix reinforced with SiC particles was obtained by SHS forced compaction of a multilayer packet of regularly packed layers of titanium foil and polymer film filled with silicon carbide particles. The particulars of the phase composition and microstructure of the material obtained were investigated.

Similar content being viewed by others

References

M. W. Barsoum and T. El-Raghy, “Synthesis and characterization of a remarkable ceramic: Ti3SiC2,” J. Am. Ceram. Soc., 79(7), 1953 – 1956 (1996).

N. F. Gao, Y. Miyamoto, and D. Zhang, “Dense Ti3SiC2 prepared by reactive HIP,” J. Mater. Sci., 34(18), 4385 – 4392 (1999).

Y. C. Zhou, Z. M. Sun, S. Q. Chen, and Y. Zhang, “In-situ hot pressing. Solid–liquid reaction synthesis of dense titanium silicon carbide bulk ceramics,” Mater. Res. Innov., No. 2, 142 – 146 (1998).

A. Feng, T. Orling, and Z. A. Munir, “Field-activated pressure-assisted combustion synthesis of polycrystalline Ti3SiC2,” J. Mater. Res., 14(3), 925 – 939 (1999).

Y. L. Bai, X. D. He, C. C. Zhu, and X. K. Qian, “Preparation of ternary layered Ti3SiC2 ceramic by SHS/PHIP,” Key Eng. Mater., 368 – 372, 1851 – 1854 (2008).

Y. Zou, Z. M. Sun, S. Tada, and H. Hashimoto, “Synthesis reactions for Ti3SiC2 through pulse discharge sintering TiH2 /Si/TiC powder mixture,” Mater. Res. Bull., 43(4), 968 – 975 (2008).

S. Konoplyuk, T. Abe, T. Uchimoto, and T. Takagi, “Ti3SiC2 /TiC composites prepared by PDS,” J. Mater. Sci., 40(13), 3409 – 3413 (2005).

T. Goto and T. Hirai, “Chemically vapor deposited Ti3SiC2,” Mater. Res. Bull., 22(9), 1195 – 1201 (1987).

S. Jacques, H. Fakih, and J.-C. Viala, “Reactive chemical vapor deposition of Ti3SiC2 with and without pressure pulses: effect on the ternary carbide texture,” Thin Solid Films, 518(18), 5071 – 5077 (2010).

W. Kraus and G. Nolze, “Powder cell — a program for the representation and manipulation of crystal structures and calculation of the x-ray powder patterns,” J. Appl. Cryst., 29(3), 301 – 303 (1996).

D. P. Riley, E. H. Kisi, T. C. Hansen, and A. W. Hewat, “Selfpropagating high-temperature synthesis of Ti3SiC2 : I. Ultrahigh speed neutron diffraction study of the reaction mechanism,” J. Am. Ceram. Soc., 85(10), 2417 – 2424 (2002).

J. M. Córdoba, M. J. Sayagués, M. D. Alcalá, and F. J. Gotor, “Synthesis of Ti3SiC2 powders: reaction mechanism,” J. Am. Ceram. Soc., 90(3), 825 – 830 (2007).

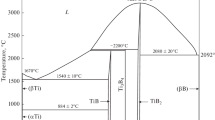

Y. Du, B. Huang, H. Liu, Y. Liu, Z. Pan, and H. Xu, “Materials Science International Team (MSIT). C–Si–Ti (carbon – silicon – titanium),” in: Ternary Alloy Systems: Phase Diagrams, Crystallographic and Thermodynamic Data, V. IV/11A4: Light Metal Systems, Part 4, Springer, N.Y. (2006).

The Russian Foundation for Fundamental Research provided the financial support for this work (Project No. 11-03-00529-a).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Steklo i Keramika, No. 11, pp. 19 – 21, November, 2011.

Rights and permissions

About this article

Cite this article

Istomin, P.V., Nadutkin, A.V. & Grass, V.É. Production of Ti3SiC2-based materials by SHS forced compaction of layered composite Ti–SiC. Glass Ceram 68, 366–368 (2012). https://doi.org/10.1007/s10717-012-9391-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10717-012-9391-7