Abstract

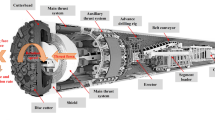

Operational parameters of a Tunnel Boring Machine (TBM) under different geological properties have significant influence on muck removal performance. To improve the muck removal performance for Yinsong Tunnel TMB, tuff and granite properties were surveyed by geological detection in the tunnel project, and the optimization of advancement and rotational speed of cutterhead was investigated. The muck model was established by discrete element method (DEM), considering the shape characteristic of muck. The whole muck removal process was simulated, then the influence of the advancement speed and rotational speed on muck removal performance in tuff and granite stratum was studied via numerical simulations. Based on simulation results, the muck removal performance evaluation system of TBM is built using fuzzy mathematics and evaluation theory. Ultimately, optimal operation parameters in the tunnel project is obtained after comprehensive evaluation. The results indicated that the optimum advancement speed should be 7 r/min in both tuff and granite stratum, while the optimal rotational speed was 6 r/min in granite and 5.5 r/min in tuff respectively. Based on TBM engineering application, the size characteristic of muck was obtained from on-site muck specimen analysis and the muck removal performance of TBM under different operation and rock conditions was compared to validate the simulation method. These findings could provide guidance for TBM operation to improve muck removal performance in different geological conditions.

Similar content being viewed by others

References

Adoko AC, Yagiz S (2019) Fuzzy inference system-based for TBM field penetration index estimation in rock mass. Geotechn Geol Eng 37(3):1533–1553

Armetti G, Migliazza MR, Ferrari F, Berti A, Padovese P (2018) Geological and mechanical rock mass conditions for TBM performance prediction. The case of “La Maddalena” exploratory tunnel, Chiomonte (Italy). Tunn Undergr Space Technol 77:115–126

Benato A, Oreste P (2015) Prediction of penetration per revolution in TBM tunneling as a function of intact rock and rock mass characteristics. Int J Rock Mech Min Sci 74:119–127

Cho JW, Jeon S (2013) Evaluation of cutting efficiency during TBM disc cutter excavation within a Korean granitic rock using linear-cutting-machine testing and photogrammetric measurement. Tunn Undergr Space Technol 35:37–54

Choi SO, Lee SJ (2015) Three-dimensional numerical analysis of the rock-cutting behavior of a disc cutter using particle flow code. KSCE J Civ Eng 19(4):1129–1138

Delisioa A, Einstein HH (2013) Analysis and prediction of TBM performance in blocky rock conditions at the Lötschberg Base Tunnel. Tunn Undergr Space Technol 33:131–142

Deng MJ (2018) Challenges and thoughts on risk management and control for the group construction of a super-long tunnel by TBM. Eng 4(1):112–122

Faramarzi L, Kheradmandian A, Azhari A (2020) Evaluation and optimization of the effective parameters on the shield TBM performance: torque and thrust—using discrete element method (DEM). Geotechn Geol Eng 38:2745–2759

Fatemi SA, Ahmadi M, Rostami J (2016) Evaluation of TBM performance prediction models and sensitivity analysis of input parameters. Bull Eng Geol Environ. https://doi.org/10.1007/s10064-016-0967-2

Geng Q, Zhang HJ, Liu XH, Wang XB (2019) Numerical study on the rock muck transfer process of TBM cutterhead with clump strategy based on discrete element method. Tunn Undergr Space Technol 91:103000

Hamidi JK, Shahriar K, Rezai B, Rostami J (2010) Performance prediction of hard rock TBM using Rock Mass Rating (RMR) system. Tunn Undergr Space Technol 25(4):333–345

Hasanpour R, Rostami J, Thewes M, Schmitt J (2018) Parametric study of the impacts of various geological and machine parameters on thrust force requirements for operating a single shield TBM in squeezing ground. Tunn Undergr Space Technol 73:252–260

Huo JZ, Chen W, Ouyang XY, Zhang X (2014) Simulation of TBM mucking process based on the ballast fluidity. Appl Mech Mater 541–542:832–835

Huo JZ, Wang W, Sun W, Ling JX, Dong J (2017) The multi-stage rock fragmentation load prediction model of tunnel boring machine cutter group based on dense core theory. Int J Adv Manuf Technol 90:277–289

Kim TH, Kim BK, Lee KH, Lee IM (2019) Soil conditioning of weathered granite soil used for EPB shield TBM: a laboratory scale study. KSCE J Civ Eng 23(4):1829–1838

Jie L, Ping C, Li K (2015) A study on isotropic rock breaking with TBM cutters under different confining stresses. Geotech Geol Eng 33(6):1379–1394

Lan H, Xia YM, Miao Bin FuJ, Ji ZY (2020) Prediction model of wear rate of inner disc cutter of engineering in Yinsong, Jilin. Tunn Undergr Space Technol 99:10338

Li R, Jin Y (2018) The early-warning system based on hybrid optimization algorithm and fuzzy synthetic evaluation model. Inform Sci 435:296–319

Naghadehi MZ, Ramezanzadeh A (2016) Models for estimation of TBM performance in granitic and mica gneiss hard rocks in a hydropower tunnel. Bull Eng Geol Environ 76(4):1–15

Park B, Min KB (2015) Bonded-particle discrete element modeling of mechanical behavior of transversely isotropic rock. Int J Rock Mech Min Sci 76:243–255

Song KZ, Ji LG, Yuan DJ, Wang MS (2008) Research on distribution regularities of grain size of rock detritus from discoid cutters. Chin J Rock Mech Eng 27:3016–3022 (in Chinese)

Sun JS, Lu WB, Su LJ, Zhou CB (2008) Rock mass rating identification based on TBM performance parameters and muck characteristics. Chin J Geotech Eng 30(12):1847–1854 (in Chinese)

Tan Q, Yi L, Xia YM (2018) Performance prediction of TBM disc cutting on marble rock under different load cases. KSCE J Civ Eng 22(4):1466–1472

Wu L, Guan T, Lei L (2013) Discrete element model for performance analysis of cutterhead excavation system of EPB machine. Tunn Undergr Space Technol 37(6):37–44

Xia YM, Lin LK, Wu D, Jia LH, Chen Z, Bian ZK (2018a) Geological adaptability matching design of disc cutter using multicriteria decision making approaches. J Cent South Univ 25:843–854

Xia YM, Guo B, Tan Q, Zhang XH, Lan H, Ji ZY (2018b) Comparisons between experimental and semi-theoretical cutting forces of CCS disc cutters. Rock Mech Rock Eng 51:1583–1597

Xia YM, Yang M, Wu D, Lin LK, Ji ZY (2018c) Influence of the TBM mucking slot structure parameters on ballast discharge characteristics. J Harbin Eng Univ 39(09):1561–1567 (In Chinese)

Xiao N, Zhou X, Gong Q (2017) The modelling of rock breakage process by TBM rolling cutters using 3D FEM-SPH coupled method. Tunn Undergr Space Technol 61:90–103

Yagiz S, Karahan H (2015) Application of various optimization techniques and comparison of their performances for predicting TBM penetration rate in rock mass. Int J Rock Mech Min Sci 80:308–315

Zhang XH, Xia YM, Tan Q, Zhu ZM (2018) Comparison study on the rock cutting characteristics of disc cutter under free-face-assisted and conventional cutting methods. KSCE J Civ Eng 22(10):4155–4162

Acknowledgements

This work is supported by the Major Science and Technology Projects of Hunan Province (Granted No. 2019GK1010), the National Natural Science Foundation of China (Granted No. 51475478), the National Basic Research Programme of China (Granted No. 2013CB035401) and Independent Exploration and Innovation Program of Central South University (Granted No. 2019zzts058).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xia, Y., Yang, M., Mei, Y. et al. Influence of Geological Properties and Operational Parameters on TBM Muck Removal Performance for Yinsong Tunnel. Geotech Geol Eng 40, 2291–2306 (2022). https://doi.org/10.1007/s10706-021-02028-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-021-02028-y