Abstract

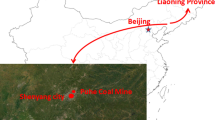

The roof and floor of transportation roadway of S2S2 working face of Xiaokang coal mine were oil shale and siltstone. The content of clay mineral in the surrounding rock was about 60–80%, which was easy to softening with water and weathering. The deformation of primary archy support roadway was serious and the repair rate was high. To control effectively the deformation of extremely soft rock roadway of Xiaokang coal mine, A combined support system of circular full closed section + high strength and pre-stress anchor + “W” strip + powerful anchor cable + shotcrete + 360U yieldable steel support + back wall filling support was suggested. By combining numerical calculation and field measurement, the convergence and convergence velocity of new circular support roadway were analyzed after excavating completion and compared with the value of primary archy support roadway. The convergence and convergence velocity of new circular support roadway significantly decreased. The deformation of surrounding rock tended to be convergent in a relatively short time. The new supporting technology was a kind of effective control method for the large deformation roadway of deep extremely soft rock. The experience for reference was provided for the support of roadway of other similar mine.

Similar content being viewed by others

References

Guo WD, Zhao P, Sun LB (2009) Xiaokang mine distribution of original rock stress research and application. Coal Technol 28(9):67–69 (in Chinese)

Guo XH, Li Z, Li KJ, Zhao H (2012) The numerical nonlinear analysis of bolt-shotcrete support for deep roadway. J Taiyuan Univ Technol 43(2):190–193 (in Chinese)

He MC (2014) Progress and challenges of soft rock engineering in depth. J China Coal Soc 39(8):1409–1417 (in Chinese)

He MC, Yuan HS, Jing HW (2004) Theory and practice of Chinese colliery bolt support. Publish House of Science, Beijing, pp 78–92 (in Chinese)

Hu YF, Xie WB, Zhao CG, Jing SG (2007) Research on backfill stress distribution technology for U type steel yield support. Coal Eng 7:66–68 (in Chinese)

Huang X, Liu QS, Qiao Z (2012) Research on large deformation mechanism and control method of deep soft roadway in Zhuji coal mine. Rock Soil Mech 33(3):827–834 (in Chinese)

Li GC, Ma ZQ, Zhang N et al (2013) Research on failure characteristics and control measures of roadways affected by multiple overhead mining in Huaibei mining area. J Min Saf Eng 30(2):181–187 (in Chinese)

Li XB, Yang RS, Gao YF, Xue HJ (2015) Study on combined support technology of bolt-mesh-shotcrete and concrete filled steel tubular supports for soft rock roadway in Yangzhuang mine. J Min Saf Eng 32(2):285–290 (in Chinese)

Lian CJ, Xu WY, Wang YJ, Wang ZH (2010) Numerical simulation of entry performance supported by a new high strength and high pretension yieldable bolts. Rock Soil Mech 31(7):2329–2335 (in Chinese)

Liang GD, Hui CD, Han CL (2010) Development and application of coal mining laneway steel timber. Energy Technol Manag 1:70–72 (in Chinese)

Liu B, Yang RS, He MC et al (2005) Design principle for truss-bolt system and its application to deep coal mine roof reinforcement. Chin J Rock Mech Eng 24(16):2875–2881 (in Chinese)

Liu C, Wei SY, Xiong Z (2012) Ultra-high strength bolt support and control technology in heading face of roadway with great buried depth. Min Res Dev 32(6):71–74 (in Chinese)

Lu YL, Wang LG, Zhang B, Li YJ (2012) Optimization of bolt-grouting time for soft rock roadway. Rock Soils Mech 33(5):1395–1401 (in Chinese)

Wang WJ, Huang WZ (2014) Deformation mechanism and rework control technology of high stress and soft rock roadway. J China Coal Soc 39(4):614–623 (in Chinese)

Wang RG, Zhang LY, Liu X et al (2007) Application and comparison of steel grid frame and steel arch in tunnel support. Sichuan Water Conserv 1:32–34 (in Chinese)

Zhang DH, Liu SH, Ren SQ (2014) Research on selection of steel and steel grid for tunnel support in softrock with high geostress. Chin J Rock Mech Eng 33(11):2258–2266 (in Chinese)

Zhang HJ, Jiao YY, Meng ZJ et al (2017) Research on application of full-closed steel grid frame in expansive soft rock roadway support. Chin J Rock Mech Eng 36(1):3392–3400 (in Chinese)

Acknowledgements

This work was supported by Liaoning province natural science foundation of China (No. 20170540143) and the National Natural Science Foundation of China (No. 51774199).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Z., Wang, C. & Wang, X. Research on High Strength and Pre-stressed Coupling Support Technology in Deep Extremely Soft Rock Roadway. Geotech Geol Eng 36, 3173–3182 (2018). https://doi.org/10.1007/s10706-018-0528-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-018-0528-5