Abstract

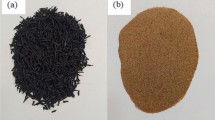

Use of tire shred–soil mixtures as backfill materials in mechanically stabilized earth walls has several advantages over other backfill materials: (1) good drainage, (2) high shear strength, and (3) low compacted unit weight. This paper presents the results of laboratory pullout tests performed on uniaxial geogrid embedded in tire shred–sand mixtures. The effects of tire shred size, tire shred–sand mixing ratio and confining pressure on the interaction between the geogrid and tire shred–sand mixtures are evaluated. Three sizes of tire shreds are considered: tire chips (with 9.5 mm nominal size), tire shreds 50-to-100 mm long and tire shreds 100-to-200 mm in length, with mixing ratios of 0, 12, 25 and 100 % of tire shreds in the mixtures (by weight). Based on compaction testing of a number of mixtures, the optimal mixing proportion of tire shreds and sand was found to lie between 25/75 and 30/70 (by weight of tire shred and sand); this is equivalent to approximately 40/60 and 50/50, respectively, by volume of tire shreds and sand. The pullout resistance of a geogrid embedded in tire shred–sand mixtures is significantly higher than that of the same geogrid embedded in tire shreds only. The size of the tire shreds has negligible effect on the pullout resistance of a geogrid embedded in mixtures prepared with either low (12/88 mix) or high (100/0 mix) tire shred content. However, when the 25/75 mixture is used, greater geogrid pullout resistance was obtained for the geogrid embedded in tire chip–sand mixtures than in tire shred–sand mixtures.

Similar content being viewed by others

References

American Society for Testing and Materials (2006) Standard specification for standard sand. ASTM C 778-06, Philadelphia, PA

American Society for Testing and Materials (2007) Standard test method for density, relative density (specific gravity), and absorption of coarse aggregate. ASTM C127-07, Philadelphia, PA

Balunaini U, Yoon S, Prezzi M, and Salgado R (2008) Tire shred backfill in mechanically stabilized earth wall applications. Report No. FHWA/IN/JTRP-2008/17, Indiana Department of Transportation, Purdue University, West Lafayette, Indiana

Balunaini U, Prezzi M (2010) Interaction of ribbed-metal strip reinforcement with tire shred–sand mixtures. Geotech Geol Eng 28(2):147–163

Basma MN, Robinson MS (2003) Use of recycled rubber tires for vibration mitigation on the Vasona light rail project. In: Rail transit conference proceedings, 2003, pp l–6

Bergado DT, Youwai S, Rittirong A (2005) Strength and deformation characteristics of flat and cubical rubber tyre chip–sand mixtures. Geotechnique 55(8):603–606

Bernal A, Salgado R, Swan RH Jr, Lovell CW (1997) Interaction between tire shreds, rubber-sand and geosynthetics. Geosynth Int 4(6):623–643

Bosscher PJ, Edil TB, Eldin NN (1992) Construction and performance of a shredded waste tire test embankment. Transportation Research Record 1345, TRB, National Research Council, Washington, DC, pp 44–52

Carraro JAH, Bandini P, Salgado R (2003) Liquefaction resistance of clean and nonplastic silty sands based on cone penetration resistance. J Geotech Geoenviron Eng 129(11):965–976

Dickson TH, Dwyer DF, Humphrey DN (2001) Prototype tire-shred embankment construction. Transportation Research Record 1755, TRB, National Research Council, Washington, DC, pp 160–167

Drescher A, Newcomb D, Heimdahl T (1999) Deformability of shredded tires. Final report, Minnesota Department of Transportation

Eldin NN, Senouci AB (1992) Use of scrap tires in road construction. J Constr Eng Manag, ASCE 118(3):561–576

Elias V, Christopher BR, Berg RR (2001) Mechanically stabilized earth walls and reinforced soil slopes, design and construction guidelines, FHWA-NHI-00-043

Hall TJ (1991) Reuse of shredded tire material for leachate collection systems. In: Proceedings fourteenth annual Madison waste conference, University of Wisconsin, Madison

Indraratna B, Wijewardena LSS, Balasubramanium AS (1993) Large-scale triaxial testing of greywacke rockfill. Geotechnique 43(1):37–51

Japan Automobile Tire Manufacturers Association (2007) Tyre recycling handbook. Japan, Tokyo, p 25

Khan RA, Shalaby A (2002) Performance of a road base constructed with shredded rubber tires. In: Proceeding of annual conference of the Canadian society for CIVIL engineering, Montreal, Quebec, Canada, June 5–8

Kuennen T (2004) Asphalt rubber makes a quiet comeback. Better Roads 74(5):32–43

Lawrence B, Humphrey D, Chen L (1999) Field trail of tire shreds as insulation for paved roads. In: Zufelt JE (ed) Proceedings of the tenth international conference on cold regions engineering: putting research into practice. ASCE, pp 428–439

Lee JH, Salgado R, Bernal A, Lovell CW (1999) Shredded tires and rubber-sand as lightweight backfill. J Geotech Geoenviron Eng, ASCE 125(2):132–141

Rao GV, Dutta RK (2006) Compressibility and strength behavior of sand-tyre chip mixtures. J Geot Geol Eng 24(3):711–724

Rubber Manufacturers Association (2011) U.S. scrap tire management summary 2005–2009. Washington, DC

Salgado R, Bandini P, Karim A (2000) Shear strength and stiffness of silty sand. J Geotech Geoenviron Eng 126(5):451–462

Salgado R and Prezzi M (2004) Construction of a tyre-shreds test embankment. Eng Sustain J, Proceedings of the Institution of Civil Engineers,157(2):65–66

Shalaby A, Khan RA (2002) Temperature monitoring and compressibility measurement of a tire shred embankment. Transportation Research Record 1808, TRB, National Research Council, Washington, DC, pp 67–75

Siddiki NZ, Kim D, Salgado R (2004) Use of recycled and waste materials in Indiana. Transportation Research Record 1874, TRB, National Research Council, Washington, DC, pp 78–85

Shulman VL (2004) Tire recycling. European Tyre Recycling Association (ETRA), vol 15, no 7, Rapra review reports

Tanchaisawat T, Bergado DT, Voottipruex P, Shehzad K (2010) Interaction between geogrid reinforcement and tire chip–sand lightweight backfill. Geotext Geomembr 28:119–127

Thevanayagam S, Shenthan T, Mohan S, Liang J (2002) Undrained fragility of clean sands, silty sands, and sandy silts. J Geotech Geoenviron Eng 128(10):849–859

Upton RJ, Machan G (1993) Use of shredded tires for lightweight fill. Transportation Research Record 1422, TRB, National Research Council, Washington, DC, pp 36–45

Warith MA, Evgin E, Benson P (2004) Suitability of shredded tires for use in landfill leachate collection systems. Waste Manag 24(10):967–979

Wolfe SL, Humphrey DN, Wetzel EA (2004) Development of tire shred underlayment to reduce ground borne vibration from LRT track. Geotechnical special publication no. 126, vol 1. In: Proceedings of Geo-Trans 2004, ASCE, pp 750–759

Yoon S (2006) Mechanical response of tire shred–sand mixtures and applications to geotechnical structures. Ph.D. thesis, School of Civil Engineering, Purdue University, West Lafayette, Indiana

Yoon S, Prezzi M, Siddiki N, Kim B (2006) Construction of a test embankment using a sand–tire shred mixture as fill material. Waste Manag 26:1033–1044

Youwai S, Bergado DT (2003) Strength and deformation characteristics of shredded rubber tire–sand mixtures. Can Geotech J 40:254–264

Youwai S, Bergado DT, Supawiwat N (2004) Interaction between hexagonal wire reinforcement and rubber tire chips with and without sand mixture. Geotech Test J 27(3):1–9

Zornberg JG, Costa YD, Vollenweider B (2004) Mechanical performance of a prototype embankment backfill built with tire shreds and cohesive soil. In: Proceeding of the 83rd TRB annual meeting, TRB, Washington, DC

Acknowledgments

This work was supported by the Joint transportation Research Program administered by the Indiana Department of Transportation and Purdue University. The contents of this paper reflect the views of the writers, who are responsible for the facts and the accuracy of the data presented herein. The contents do not necessarily reflect the official views or polices of the Federal Highway Administration and the Indiana Department of Transportation, nor do the contents constitute a standard, specification, or regulation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Balunaini, U., Yoon, S., Prezzi, M. et al. Pullout Response of Uniaxial Geogrid in Tire Shred–Sand Mixtures. Geotech Geol Eng 32, 505–523 (2014). https://doi.org/10.1007/s10706-014-9731-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-014-9731-1