Abstract

Gypseous soils are distributed in vast areas and various regions of Iraq and other countries. Many foundation failure problems that occur in these soils are associated with percolation of water and dissolution of gypsum. Many attempts were made by several researchers to treat and improve the properties of gypseous soils to decrease the dissolution of gypsum and collapse potential of these soils. The purpose of the present work is to investigate the effect of dynamic compaction process on the behaviour of gypseous soils. Extensive laboratory tests are carried out to study the geotechnical properties and the behaviour of three gypseous soils of different gypsum contents; 60.5, 41.1 and 27 %. The tests included compaction characteristics, compressibility, and collapsibility tests for samples tested before and after treatment by dynamic compaction process under different number of blows, falling weights and heights of falling of the weights. Three weights are used to compact the samples, namely; 2, 3 and 5 kg. The number of blows is varied between 20 and 40, while three heights of drop are tried (35, 50 and 65) cm. The results showed that the best improvement in compressibility is achieved when the sample is compacted by 20 blows; above this number a negligible decrease in the compression index CC is obtained. As the gypsum content increases, the dynamic compaction has greater effect on improvement of compressibility of the soil, while as the height of drop increases, the compression index CC decreases.

Similar content being viewed by others

1 Introduction

Gypsiferous soils are soils that contain sufficient quantities of gypsum (calcium sulphate) to interfere with plant growth (Nettleton et al. 1982). They occupy about 90 million ha across Algeria, Argentina, Australia, Iraq, Libya, Somalia, Spain, Sudan, Syria, the former USSR and other arid and semi-arid countries with annual rainfall of less than 500 mm (FAO 1990).

In Iraq, gypseous soils cover wide areas, sometimes with high gypsum content that exceeds the soil content, and today engineering properties of these soils in some areas are unknown. The basin of Iraq covers more than about 30 % of Iraqi area (Nashat 1994).

Gypseous soils usually stiff when they are dry, but these soils may be affected greatly when subjected to changes in water content due to water table fluctuation, or due to water infiltration which may dissolve gypsum causing, pores, cracks and producing cavities that lead to increase the permeability in gypseous soils. Therefore, the safety and good performance of the foundations of structures and earth structures, such as embankments and dams, will be governed by the changes in the properties of these soils.

Rollins et al. (1998) evaluated the influence of moisture content on dynamic compaction efficiency at six field test cells, each with a progressively higher average moisture content. The soil profile consisted of collapsible sandy silt, and average test cell moisture contents ranged from 6 to 20 %. At each cell, compaction was performed with a 4.54 ton weight dropped from a height of 24.3 m. Compaction efficiency was evaluated using (1) crater depth measurements, (2) cone penetration tests before and after compaction, and (3) undisturbed samples before and after compaction. It was found that crater depth increased by a factor of 4 as moisture content increased. The degree of improvement increased up to a moisture content of about 17 % and then decreased. The optimum moisture content and the maximum dry unit weight are similar to those predicted by laboratory Proctor testing using energy levels comparable to those employed in the field. Maximum dry unit weight decreased with depth, while optimum moisture content increased before the compactive energy decreased with depth below the impact point.

Rollins and Mark (2005) described the dynamic compaction carried out in Wyoming. The deep dynamic compaction (DDC) work typically involved a 20 ton weight, 4 ft (1.22 m) in diameter, with a drop height of 100 ft (30.48 m). Generally, primary drop points were spaced at 10 and 12 ft (3.05 and 3.66 m) on centers transverse and parallel to the direction of traffic, respectively. Secondary drops were spaced at the center of four primary drop points. Five drops were typically made at each primary drop point and 2 at each secondary point. The number of drops per point was typically limited to 5 or 6 for the primary points and 2–3 for the secondary points. The applied energy per volume increased from about 60 % of the standard Proctor test energy in the 1989–1990 work to about 95 % for the second set of tests. These relatively high energy levels are common for treating collapsible soils. Inspectors monitored the number of drops and the crater depth for each drop point. The average crater depths were typically between 5 and 7 ft (1.52 and 2.13 m) deep after treatment and the crater diameter typically increased to about 10 ft (3.05 m) at the ground surface. Dynamic cone penetration tests were performed at several locations along each roadway section before and after treatment. Substantial increases in cone penetration resistance occurred when soil types consisted of silty sands (SM) or low-plasticity silts (ML or CL-ML) and the natural water content was relatively low. In these cases, the average penetration resistance increased from an average of 5–7 blows/ft to an average of 25–30 blows/ft. However, in cases where the soil profile contained layers of plastic clay (CH) with higher natural water contents, little improvement in penetration resistance was observed. Under these conditions, the clay soil appeared to absorb a significant percentage of the impact energy rather than transmitting it to the deeper layers.

Rollins and Kim (2010) presented case histories provided for 15 projects at 10 locations in the United States where collapsible soils were treated with dynamic compaction (DC). For each site, the soil properties, compaction procedures, and subsequent improvement were summarized. Although cohesionless and low-plasticity collapsible soils were successfully compacted, clay layers in the profile appeared to absorb energy and severely reduced compaction effectiveness. Correlations were presented for estimating the maximum depth of improvement, the degree of improvement versus depth, the depth of craters, and the level of vibration based on measurements made at the various sites. The compactive energy per volume was typically higher than for non-collapsible soils because collapsible soils are usually loose but relatively stiff. The maximum depth of improvement was similar to that for non-collapsible soils; however, significant scatter was observed about the best-fit line. Improvement was non-uniform with nearly 80 % of the total improvement occurring within the top 60 % of the improvement zone. The crater depth was related to a number of factors besides the drop energy including the number of drops, drop spacing, and contact pressure.

1.1 Problems with Gypseous Soils

The problems encountered in gypseous soils are summarized in the following points as reported by Saaed (1990) and Al-Abdullah (1996):

-

Great losses in strength upon wetting.

-

Sudden increase in compressibility upon wetting.

-

Continuation of deformation and collapse upon leaching due to water movement.

-

The existence of cracks due to seasonal changes.

-

The existence of sink holes in the soil due to local dissolution of gypsum.

1.2 Improvement of Gypseous Soils

The improvement of gypseous soils means decreasing the effect of water on the gypseous soils to ensure the safety and stability of the engineering structures. This treatment can be achieved chemically or physically:

-

The chemical treatment means that the soil properties are improved with some chemical additives, such as lime, cement, bituminous, bentonite, dehydrate calcium chloride, etc.

-

The physical treatment means that the soil properties are improved using mechanical methods, such as compaction, soil reinforcement, dynamic compaction, pre-wetting, soil replacement and others.

The major purpose of this study is to make an attempt to improve gypseous soil characteristics using a dynamic compaction process. A special apparatus is manufactured to compact the soil. Different soils having different gypsum contents are used to study the effect of dynamic compaction on improving the collapsibility characteristics of these soils.

2 Experimental Work

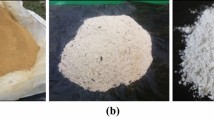

This section includes description of the sampling methods, the testing apparatus used in addition to the procedures of testing. Three types of natural gypsuous soils used in this study are taken from three locations of Al-Garmaa in Al-Anbar governorate western Iraq. The first and second soil samples are taken from a depth of 1.0 m and the third sample is obtained from a depth of 2.0 m below the natural ground surface. The samples are tested in the Soil Mechanics Laboratory at Al-Mustansiriya University in Baghdad. The samples were remolded to control the soil density.

A detailed testing program included the main tests conducted on the samples. The testing program in this study can be summarized in the following groups:

-

Classification tests are performed first including physical and chemical tests. The physical tests include specific gravity, Atterberg limits, grain size distribution and water content, while chemical tests are preformed to determine the chemical components of the samples.

-

Standard Proctor and modified Proctor compaction tests are carried out to determine the moisture-density relationships.

-

Compressibility test is performed using oedometer apparatus. Double oedometer tests are carried out on soaked and unsoaked samples at untreated and compacted states.

2.1 Physical Tests

The specific gravity of the soil is determined according to the British standards (BS 1377: 1990, Test No. 6 B; Head 2006), but “Kerosene” is used instead of water due to the dissolution of gypsum in water. The liquid limit test is carried out in accordance with (BS 1377: 1990, Test 2A), using cone penetrometer method. The plastic limit is determined in accordance with (BS 1377: 1990, Test No. 3). The liquid and plastic limits are carried out on soil passing sieve No. 40 and the temperature used for drying is maintained at (45–50) °C due to the presence of gypsum in the soil (ASTM 2216 1998).

The grain size distribution is determined by sieve analysis test, which is conducted in accordance with (ASTM D422 2002) with dry sieving.

The water content is performed in accordance with (BS 1377: 1990, Test (A); Head 2006). The water content is determined at drying temperature of 45 °C because the soil contains a significant amount of gypsum, thus preventing the loss of crystal water is required.

2.2 Chemical Tests

Several chemical tests are carried out on the samples. These tests included:

-

Total soluble salts TSS % which are determined according to the BS 1377: (1990), Test 9.

-

Total content of SO3% which is determined according to BS 1377.

In this study, the gypsum content is determined by two methods:

-

1.

Gypsum content is determined according to the British standards (BS 1377: 1990), The gypsum content is determined from the sulfate content of the soil by the following equation (BS 1377: 1990):

$$ \chi \,(\% ) = {\text{SO}}_{3} \times 2.15 $$(1) -

2.

The gypsum content is also found according to the method suggested by Al-Mufty and Nashat (2000). This method consists of oven drying the soil at 45 °C until the weight of the sample becomes constant. The weight of sample at 45 °C is recorded. Then, the same sample is dried at 110 °C until the weight becomes constant and recorded.

The gypsum content is calculated according to the following equation:

where χ = Gypsum content (%), W 45 °C = Weight of the sample at 45 °C, W 110 °C = Weight of the sample at 110 °C.

2.3 Mechanical Tests

2.3.1 Compaction Tests

Standard and modified compaction tests are carried out for the untreated soils to determine the moisture-unit weight relationship.

-

1.

Standard Compaction Test: This test is performed according to (ASTM D698, Method A 2003).

-

2.

Modified Compaction Test: This test is carried out according to (ASTM D1557, Method A 2003).

2.3.2 Compressibility Tests

A series of oedometer tests is performed in accordance with (ASTM 2435 2002). These tests are carried out on untreated and compacted samples to determine the compressibility characteristics. To conduct the tests, the fixed type consolidometer cells and loading frame with specimens of 75 mm diameter and 20 mm height are used.

2.4 Double Oedometer Test

This test is conducted according to the procedure suggested by Jennings and Knight (1957). In this test, two identical samples are tested independently. The first one is loaded without the addition of any water (unsoaked). Another sample is soaked and then loaded progressively as in the standard consolidation test. Both samples are stressed beginning from (25) kPa. Then, the test is continued following the standard procedure of doubling the applied loads until a stress of 800 kPa is reached. The sample is then unloaded by stress decrements through two stages 400 and 200 kPa. The difference between the two compression curves quantifies the amount of deformation that would occur at any stress level if the soil to be saturated during its loading history.

2.5 Description of Dynamic Compaction Apparatus

The full details of the soil dynamic compaction apparatus can be shown in Fig. 1. All components of apparatus are made of rigid steel. Generally, the apparatus consists of:

2.5.1 The Compaction Box

It is a steel box of (50 × 50 × 35) cm dimensions which has a gate in order to make the operation of extrusion of the compacted samples easy. The box can be moved by a group of rollers.

2.5.2 Compaction Arm

It is a steel pipe having the form of letter (L) connected from the bottom with a steel base of dimensions (36 × 36) cm. The side part of compaction arm is a steel pipe of length L = 40 cm and diameter D = 9 cm, it ends with a toothed crow bar rotated manually by hand for controlling the height of falling of weights and to ensure free fall of the weights. This is done through controlling length of the metal wire, with which it is connected during the movement of the toothed crow bar of other side. The middle part of the compaction arm is interfered pipe of steel. The outer pipe which is connected to the base of the arm has dimensions of inner diameter ID = 10 cm, outer diameter OD = 11 cm and height H = 100 cm. The interior pipe which is connected to the side part has dimensions of D = 9 cm and H = 75 cm.

3 Preparation of the Soil Sample

In this study, compacted soil samples are prepared at moisture content equal to the optimum moisture content according to ASTM D698 (2003). The preparation of the soil sample is summarized in the following:

4 Soil Compaction by Dynamic Compaction Apparatus

-

1.

The compaction box is filled with soil. The soil layer thickness in the box is limited to 20 cm due to sample preparation requirements. It is known from previous studies on dynamic compaction, such as Rollins and Mark (2005), that for the used loads, 2.5–4 cm is the effective depth of influence of dynamic compaction, from which it is sufficient to obtain samples (after dynamic compaction) for oedometer test. The soil is compacted through the falling weights at different heights and the required number of blows. In this study, three weights of 2, 3 and 5 kg are used with three heights of falling 35, 50 and 65 cm and three different numbers of blows; 20, 30 and 40 are tried.

-

2.

The required weight is fastened by the metal wire and raised to the specific height by moving the hold by hand then it is locked with the toothed crow bar.

-

3.

The lock of the crow bar is opened, and then the weight falls freely on the soil. This operation is repeated to reach the required number of blows. The loads are controlled to be distributed at enough area for extraction of at least two samples of the compacted soil which are necessary for preparing samples for oedometer test. The box is to be rolled by hand to ensure distribution of the blows over the required area.

-

4.

Two rings of the oedometer test apparatus are pushed in the compacted space of the soil to get the required samples for oedometer test.

-

5.

The gate of the compaction box is opened to extract the samples.

5 Results and Discussion

5.1 Grain Size Distribution

The results of particle size distribution tests conducted using dry sieve analysis are shown in Fig. 2. From these results, the soil specimens S1, S2 and S3 can be classified according to the Unified Soil Classification System (USCS) as poorly graded—silty sand (SP − SM). It should be noticed that the classification of gypseous soil depends on the state of testing or method of calculation. Some researchers pretreated the gypseous soil with a solution such as EDTA (Ethylenediaminetetraacetic acid) (Seleam 1988) or large amount of distilled water to remove the gypsum prior to carrying out the classification tests, while others used kerosene or white spirit to prevent any more dissolution of gypsum from the soil sample.

5.2 Specific Gravity

It can be noticed that the specific gravity decreases for the soil having high gypsum content. The low specific gravity of the three soils, which ranges between 2.28 and 2.41 is attributed to the low specific gravity of gypsum, which is equal to 2.32, compared to other soil constituents.

5.3 Atterberg Limits

Atterberg limits tend to increase with the increase of gypsum content (Al-Gabri 2003). This behaviour may be related to the small particles of gypsum, which cause an increase in the surface area of the soil, the requirements of water are increased until these limits. Similar results are found in this study as can be noticed in Table 1 in which the liquid limit values are high despite that the soil is granular. This may be attributed to the fact that the soil has apparent cohesion caused by the presence of gypsum which gives the soil the consistency of fine soil. The results of Atterberg limits are summarized in Table 1.

5.4 Chemical Tests

Table 2 shows the results of chemical tests. Since the gypsum content of the three soils is more than (25 %); the soils are classified according to Barzanji (1973) as “highly gypsiferous”.

5.5 Compaction Testes

The results of compaction tests are tabulated in Table 3. The relationships between dry unit weight and water content for the tested soils are shown in Fig. 3 for compactive efforts associated with the modified and standard Proctor test.

It is noticed that the standard maximum dry unit weight of soil S2 is somewhat higher than the standard maximum dry unit weight of soil S1, while the opposite is true for the modified compaction test. This is due to the role of gypsum in the compaction (Al-Mufty 1997): First, the gypsum particles act as pore filling fines especially if the gypsum particles are of small size compared to the soil grains, thus, increasing the dry unit weight. Second, gypsum causes cementation to soil particles that helps resistance to compaction effort and increases the required water content to reach the maximum unit weight. In other words, the decrease in the maximum dry unit weight may be attributed to the loss of some compactive energy in breaking the cementation bonds, which may form between clay and gypsum particles. Third, increasing gypsum at the expense of soil particles causes a lower specific gravity for the soil as a whole, and leads to decreasing the dry unit weight.

It can be concluded from the water content—unit weight relationships that the test results depend on the soluble salt content (gypsum content), water content, the solubility degree of gypsum in water and compactive effort. This agrees with the findings of Farwana and Majid (1988).

5.6 Compression Test

This test is carried out on two samples for each soil. The first sample is tested at the optimum water content, while the other is directly tested after soaking in water. The results are presented as void ratio versus logarithm of effective stress as shown in Figs. 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16 for all tested specimens. Figure 4 presents the relationship for the untreated samples, while Figs. 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16 show the relationship for samples tested after treatment by dynamic compaction under different numbers of blows, falling weights and height of falling of the weights.

From these results, it can be seen that:

-

The initial void ratio eo for the compacted sample of soil S1 is greater than the initial void ratio of soils S2 and S3. This is due to the effect of gypsum content. The presence of gypsum enlarges the voids within the soil structure.

-

The void ratio at stress level 800 kPa increases slightly with the increase in the height of drop H from 35 cm to 50 cm, but decreases under H = 65 cm.

-

The void ratio at stress level 800 kPa for soaked compacted samples decreases with the increase in the falling weight.

-

The void ratio at stress level 800 kPa for soaked compacted samples decreases with the increase in the number of blows.

-

In samples subjected to dynamic compaction, the change in void ratio ∆e upon soaking becomes smaller than that of untreated samples which means that the collapse potential decreases.

In Figs. 17, 18, 19, the compression index CC is plotted versus the number of blows. It becomes clear that the compression index for soil S1 increases from 0.011 to 0.221 upon soaking in water. The same behaviour is observed for the other two soils, as shown in Table 4. This behaviour is attributed to the fact that the gypsum acts as cementing material by adding resistance to deformation, but upon wetting, softening occurs due to cement loss.

It can be also noticed that, for saturated soil samples, the compression index decreases as the sample is compacted under a number of blows among 20-40. The best improvement in compressibility is achieved when the sample is subjected to 20 drops. Above this number, a negligible decrease in C C is obtained. For soil S1, as the number of blows increases, the C C increases due to the increase in the height of drop, while for soils S2 and S3, the large number of blows greater than 30 may lead to increase C C . This may be attributed to breakage of soil grains and a decrease in particle interlocking and hence increase in void ratio. The decrease in compression index ranges between 0.152 and 0.044 %, while soil S1 shows inverse behaviour. This behaviour is attributed to the effect of gypsum content.

The dry samples show inverse behaviour; the compression indices increase when samples are compacted under 20 blows, then this increase becomes smaller when the number of blows increases further. The reason for this can also be attributed to breaking of particles which in turn causes an increase in void ratio.

The height of drop has a noticeable effect on C C values. As the height of drop increases from 35 cm to 65 cm, the compression index decreases. This effect is greater in samples S1 and S2 than sample S3. As the gypsum content increases, the dynamic compaction has greater effect on the improvement of compressibility of the soil. It can be seen that the best improvement in C C takes place for soil S2 where the gypsum content, χ = 41.1 %, after which, this gain decreases.

The same behaviour can be seen in Figs. 20, 21, 22, which show the relationship between the rebound index Cr and the number of blows for samples compacted at different weights and heights of drop. Generally, from these figures, it can be noticed that for soaked soil sample S1, Cr increases with increasing the number of blows, while for the unsoaked sample, Cr decreases at a number of blows equals to 30 then it increased at a number of blows equals to 40.

For soil S2, it can be observed that for soaked samples, Cr decreases with increasing the number of blows, while for the unsoaked samples, Cr decreases at a number of blows equals to 30, then it increased at a number of blows equals to 40. The opposite is true for soil S3.

The improvement in Cr decreases with the increase in gypsum content. The improvement is greater for sample S3 where χ = 27 %. This may be attributed to the presence of gypsum fragments within these soils, whose crystallization structures have extremely strong structural bonds, but are very brittle and are irreversibly destroyed by mechanical action during the loading stage (Petrukhin and Arakelyan 1985; Al-Qaissy 1989).

6 Conclusions

In this work, three samples with different gypsum contents are treated by both standard compaction tests and dynamic compaction apparatus. From the results and analysis of the tests on soil samples with gypsum content 60.5, 41.1 and 27 %, the following conclusions can be made:

-

1.

The best improvement in compressibility is achieved when the samples are subjected to 20 drops, this conclusion is based on the improvement of compression index of soaked samples obtained after treatment. Above this number, a negligible decrease in the compression index CC is obtained.

-

2.

As the height of drop increases from 35 to 65 cm, the compression index CC decreases. This effect increases with the increase in the gypsum content. The same behaviour of the compression index CC can be noticed on the rebound index Cr.

-

3.

As the gypsum content increases, the dynamic compaction has greater effect on improvement of compressibility of the soil. In samples subjected to dynamic compaction, the change in void ratio ∆e upon soaking becomes smaller than that of untreated samples which means that the collapse potential decreases.

References

Al-Abdullah SFI (1996) The upper limit of gypseous salts in the clay core of AI-Adhaim Dam. Ph.D. Thesis, Department of Civil Engineering, University of Baghdad, Iraq

Al-Gabri MKA (2003) Collapsibility of gypseous soils using three different methods. M.Sc. Thesis, Building and Construction Engineering Department, University of Technology, Baghdad, Iraq

Al-Mufty AA (1997) Effect of gypsum dissolution on the mechanical behavior of gypseous soils. Ph.D. Thesis, Civil Engineering Department, University of Baghdad, Iraq

Al-Mufty AA, Nashat EH (2000) Gypsum content determination in gypseous soils and rocks. In: Proceedings of the 3th Jordanian international mining conference, Amman, vol 2, pp 485–492

Al-Qaissy FF (1989) Effect of gypsum content and its migration on compressibility and shear strength of the soil. M.Sc. Thesis, Building and Construction Engineering Department, University of Technology, Baghdad, Iraq

ASTM D2216 (1998) Standard test method for laboratory determination of water (moisture) content of soil and rock by mass. Annual book of ASTM standards, vol 04.08, ASTM international, West Conshohocken, PA, pp 1–5

ASTM D422 (2002) Standard test method for particle size analysis of soils. Annual book of ASTM standards, vol 04.08, ASTM International, West Conshohocken, PA, pp 1–8

ASTM D2435 (2002) Standard test method for one-dimensional consolidation properties of soils. Annual book of ASTM standards, vol 04.08, ASTM international, West Conshohocken, PA, pp 1–10

ASTM D698 (2003) Standard test method for laboratory compaction characteristics of soil using standard effort. Annual book of ASTM standards, vol 04.08, ASTM international, West Conshohocken, PA, pp 1–8

ASTM D1557 (2003) Test methods for laboratory compaction characteristics of soil using modified efforts. Annual book of ASTM standards, vol 04.08, ASTM international, West Conshohocken, PA, pp 1–8

Barzanji AF (1973) Gypesous soil of Iraq. Ph.D. Thesis, University of Ghent, Belgium

BS 1377 - 2 (British Standard Institution) (1990) Method of test for soils for civil engineering purposes. British Standard Institution, London, UK

FAO (1990) Management of gypsiferous soils. FAO Soils Bull 62

Farwana TA, Majid ZK (1988) An investigation into the use of emulsified asphalt in the stabilization of sandy sabkha. In: Proceedings of the 3rd IRF Middle East, Regional Meeting, Kingdom of Saudi Arabia

Head KH (2006) Manual of soil laboratory testing, Vol. 1, Soil classification and compaction tests, 3rd edn. Whittles publishing, UK

Jennings JK, Knight K (1957) The additional settlement of foundation due to a collapse of structure of sandy subsoil on wetting. In: Proceedings of 4th international conference on soil mechanics and foundation engineering, vol 2, pp 316–319

Nashat IH (1994) Exploit of gypseous soil. Report, Ministry of Housing and Construction—National Center for Construction Laboratories NCCL, Baghdad, Iraq, pp 54–63

Nettleton WD, Nelson RE, Brasher BR, Derr PS (1982) Gypsiferous soils in the Wester United States. In: Soil Science Society of America Special Publication, No. 10, pp 147–168

Petrukhin VP, Arakelyan EA (1985) Strength of gypsum-day soils and its variation during the leaching of salts. J Soil Mech Found Eng 21(6):23–25

Rollins KM, Kim J (2010) Dynamic compaction of collapsible soils based on U.S. case histories. J Geotech Geoenviron Eng ASCE 136(9):1178–1186

Rollins KM, Mark F (2005) Dynamic deep compaction treatment of collapsible soils in Wyoming. Salt Lake City annual meeting, October 16–19, 2005, Geological Society of America Abstracts with Programs, vol 37, No. 7, p 328

Rollins KM, Jorgensen ST, Ross TE (1998) Optimum moisture content for dynamic compaction of collapsible soils. J Geotech Geoenviron Eng ASCE 124(8):699–708

Saaed SA (1990) Characteristics of gypseous soil. Almuhandisson J (3):23–35

Seleam SNM (1988) Geotechnical characteristics of a gypseous sandy soil including the effect of contamination with some oil products. M.Sc. Thesis, Building and Construction Engineering Department, University of Technology, Baghdad, Iraq

Open Access

This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Fattah, M.Y., al-Musawi, H.H.M. & Salman, F.A. Treatment of Collapsibility of Gypseous Soils by Dynamic Compaction. Geotech Geol Eng 30, 1369–1387 (2012). https://doi.org/10.1007/s10706-012-9552-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-012-9552-z