Abstract

Recent experiments in bonded PMMA layers have shown dramatic changes in dynamic crack growth characteristics depending on the interface location and its toughness. We present a peridynamic (PD) analysis of the problem and identify three necessary elements in a model aimed at reproducing the observed dynamic fracture behavior at an interface in PMMA: (1) softening near the crack tip to account for changes in PMMA properties due to heat-generation induced by the high strain rates reached around the crack tip in dynamic fracture, (2) independence of extension (mode I) and shear (mode II) modes of fracture, and (3) a two-parameter bond-failure model, that can match both strength and fracture toughness for any horizon size. The PD model with these elements captures the experimentally observed dynamic fracture characteristics in bi-layer PMMA: the presence/absence of crack branching at the interface, depending on the interface location; cracks running along the interface for a while before punching through the second PMMA layer; slight crack path oscillations as the cracks approach the free surface. The computed crack speed profiles are close to those measured experimentally. The simulations help explain the observed behavior of dynamic crack growth through an interface. The model shows an enlargement of the fracture process zone when the cracks running along the interface penetrate into the second PMMA layer, as observed experimentally. This is where nonlocality of the PD model becomes relevant and critical.

Similar content being viewed by others

Notes

Please note that, while not specified in reference (Li et al. 2020), this formulation is valid only for infinitesimal deformations and infinitesimal rotations. These conditions are met in the impact problem discussed in our paper, but for a problem with large deformations, the more general state-based PD model should be used.

References

Abdel-Wahab AA, Ataya S, Silberschmidt VV (2017) Temperature-dependent mechanical behaviour of PMMA: Experimental analysis and modelling. Polym Test 58:86–95. https://doi.org/10.1016/j.polymertesting.2016.12.016

Acharya S, Mukhopadhyay AK (2014) High strain rate compressive behavior of PMMA. Polym Bull 71(1):133–149. https://doi.org/10.1007/s00289-013-1050-9

Atkins AG, Lee CS, Caddell RM (1975) Time-temperature dependent fracture toughness of PMMA - Part 1. J Mater Sci 10(8):1381–1393. https://doi.org/10.1007/BF00540829

Basu S, Van der Giessen E (2002) A thermo-mechanical study of mode I, small-scale yielding crack-tip fields in glassy polymers. Int J Plast 18(10):1395–1423. https://doi.org/10.1016/S0749-6419(02)00009-8

Bobaru F, Zhang G (2015) Why do cracks branch? A peridynamic investigation of dynamic brittle fracture. Int J Fract 196:59–98. https://doi.org/10.1007/s10704-015-0056-8

Bobaru F, Yang M, Alves LF, Silling SA, Askari E, Xu J (2009) Convergence, adaptive refinement, and scaling in 1D peridynamics. Int J Numer Methods Eng 77(6):852–877. https://doi.org/10.1002/nme.2439

Bobaru F, Ha YD, Hu W (2010) Numerical integration in peridynamics. Technical report

Bobaru F, Ha YD, Hu W (2012) Damage progression from impact in layered glass modeled with peridynamics. Central Eur J Eng 2(4):551–561. https://doi.org/10.2478/s13531-012-0020-6

Bußler M et al (2017) Visualization of fracture progression in peridynamics. Computers and Graphics (pergamon) 67:45–57. https://doi.org/10.1016/j.cag.2017.05.003

Chen W-C, Lee S-J, Ho B-C (1998) Diffusion coefficients of acrylic monomers in poly (methyl methacrylate). J Polym Res 5(3):187–191. https://doi.org/10.1007/s10965-006-0055-6

Crank J (1979) The mathematics of diffusion. Oxford University Press, Oxford

Diana V, Casolo S (2019) A bond-based micropolar peridynamic model with shear deformability: Elasticity, failure properties and initial yield domains. Int J Solids Struct 160:201–231. https://doi.org/10.1016/j.ijsolstr.2018.10.026

Dondeti S, Tippur HV (2019) A Hybrid Experimental-Numerical Study of Crack Initiation and Growth in Transparent Bilayers Across a Weak Interface. In: Kimberley J, Lamberson LE, Mates S (eds) Dynamic Behavior of Materials, vol 1. Springer, Cham, pp 57–63

Fuller KNG, Fox PG, Field JE (1975) The temperature rise at the tip of fast-moving cracks in glassy polymers. Proc R Soc Lond A 341(1627):537–557. https://doi.org/10.1098/rspa.1975.0007

Gori M, Rubino V, Rosakis AJ, Lapusta N (2018) Pressure shock fronts formed by ultra-fast shear cracks in viscoelastic materials. Nat Commun. https://doi.org/10.1038/s41467-018-07139-4

Ha YD, Bobaru F (2010) Studies of dynamic crack propagation and crack branching with peridynamics. Int J Fract 162(1–2):229–244. https://doi.org/10.1007/s10704-010-9442-4

Ha YD, Bobaru F (2011) Characteristics of dynamic brittle fracture captured with peridynamics. Eng Fract Mech 78(6):1156–1168. https://doi.org/10.1016/j.engfracmech.2010.11.020

Hu YL, Madenci E (2016) Bond-based peridynamic modeling of composite laminates with arbitrary fiber orientation and stacking sequence. Compos Struct 153:139–175. https://doi.org/10.1016/j.compstruct.2016.05.063

Hu W, Wang Y, Yu J, Yen CF, Bobaru F (2013) Impact damage on a thin glass plate with a thin polycarbonate backing. Int J Impact Eng 62:152–165. https://doi.org/10.1016/j.ijimpeng.2013.07.001

Jafarzadeh S, Chen Z, Bobaru F (2018a) Peridynamic modeling of intergranular corrosion damage. J Electrochem Soc 165(7):C362. https://doi.org/10.1149/2.0821807jes

Jafarzadeh S, Chen Z, Bobaru F (2018b) Peridynamic modeling of repassivation in pitting corrosion of stainless steel. Corrosion 74(4):393–414. https://doi.org/10.5006/2615

Jafarzadeh S, Wang L, Larios A, Bobaru F (2021) A fast convolution-based method for peridynamic transient diffusion in arbitrary domains. Comput Methods Appl Mech Engrg 375:113633. https://doi.org/10.1016/j.cma.2020.113633

Jafarzadeh S, Mousavi F, Wang L, Bobaru F (2023) PeriFast/Dynamics: a MATLAB code for explicit fast convolution-based peridynamic analysis of deformation and fracture. J Peridyn Nonlocal Model. https://doi.org/10.1007/s42102-023-00097-6

Kramer EJ, Berger LL (1990) Fundamental processes of craze growth and fracture. Crazing in Polymers, vol 2. Springer, Berlin, pp 1–68

Kreyszig E (2011) Advanced Engineering Mathematics. Wiley, Hoboken

Le QV, Bobaru F (2018) Surface corrections for peridynamic models in elasticity and fracture. Comput Mech 61(4):499–518. https://doi.org/10.1007/s00466-017-1469-1

Li WJ, Zhu QZ, Ni T (2020) A local strain-based implementation strategy for the extended peridynamic model with bond rotation. Comput Methods Appl Mech Eng 358:112625. https://doi.org/10.1016/j.cma.2019.112625

Lu X, Chen BY, Tan VBC, Tay TE (2018) A separable cohesive element for modelling coupled failure in laminated composite materials. Compos Part A Appl Sci Manuf 107:387–398. https://doi.org/10.1016/j.compositesa.2018.01.014

Madenci E, Dorduncu M, Barut A, Phan N (2018) A state-based peridynamic analysis in a finite element framework. Eng Fract Mech 195:104–128. https://doi.org/10.1016/j.engfracmech.2018.03.033

Madenci E, Barut A, Phan N (2021) Bond-based peridynamics with stretch and rotation kinematics for opening and shearing modes of fracture. J Peridyn Nonlocal Model. https://doi.org/10.1007/s42102-020-00049-4

Mehrmashhadi J, Chen Z, Zhao J, Bobaru F (2019a) A stochastically homogenized peridynamic model for intraply fracture in fiber-reinforced composites. Compos Sci Technol 182:107770. https://doi.org/10.1016/j.compscitech.2019.107770

Mehrmashhadi J, Wang L, Bobaru F (2019b) Uncovering the dynamic fracture behavior of PMMA with peridynamics: the importance of softening at the crack tip. Eng Fract Mech 219:106617. https://doi.org/10.1016/j.engfracmech.2019.106617

Mehrmashhadi J, Bahadori M, Bobaru F (2020) On validating peridynamic models and a phase-field model for dynamic brittle fracture in glass. Eng Fract Mech 240:107355. https://doi.org/10.1016/j.engfracmech.2020.107355

Niazi S, Chen Z, Bobaru F (2021) Crack nucleation in brittle and quasi-brittle materials: A peridynamic analysis. Theoret Appl Fract Mech 112:102855. https://doi.org/10.1016/j.tafmec.2020.102855

Rao SS (2019) Engineering optimization: theory and practice. Wiley, Hoboken

Ravi-Chandar K, Yang B (1997) On the role of microcracks in the dynamic fracture of brittle materials. J Mech Phys Solids 45(4):535–563

Ren B, Wu CT, Askari E (2017) A 3D discontinuous Galerkin finite element method with the bond-based peridynamics model for dynamic brittle failure analysis. Int J Impact Eng 99:14–25. https://doi.org/10.1016/j.ijimpeng.2016.09.003

Sahputra IH, Alexiadis A, Adams MJ (2018) Temperature and configurational effects on the Young’s modulus of poly (methyl methacrylate): a molecular dynamics study comparing the DREIDING, AMBER and OPLS force fields. Mol Simul 44(9):774–780. https://doi.org/10.1080/08927022.2018.1450983org/10.1080/08927022.2018.1450983

Sarego G, Le QV, Bobaru F, Zaccariotto M, Galvanetto U (2016) Linearized state-based peridynamics for 2-D problems. Int J Numer Methods Eng 108(10):1174–1197. https://doi.org/10.1002/nme.5250

Seleson P (2014) Improved one-point quadrature algorithms for two-dimensional peridynamic models based on analytical calculations. Comput Methods Appl Mech Eng 282:184–217. https://doi.org/10.1016/j.cma.2014.06.016

Silling SA (2000) Reformulation of elasticity theory for discontinuities and long-range forces. J Mech Phys Solids 48(1):175–209. https://doi.org/10.1016/S0022-5096(99)00029-0

Silling SA, Askari E (2005) A meshfree method based on the peridynamic model of solid mechanics. Comput Struct 83(17–18):1526–1535. https://doi.org/10.1016/j.compstruc.2004.11.026

Silling SA, Epton M, Weckner O, Xu J, Askari E (2007) Peridynamic states and constitutive modeling. J Elast 88(2):151–184. https://doi.org/10.1007/s10659-007-9125-1

Song JH, Wang H, Belytschko T (2008) A comparative study on finite element methods for dynamic fracture. Comput Mech 42(2):239–250. https://doi.org/10.1007/s00466-007-0210-x

Sundaram BM, Tippur HV (2016a) Dynamics of crack penetration vs. branching at a weak interface: an experimental study. J Mech Phys Solids 96:312–332. https://doi.org/10.1016/j.jmps.2016.07.020

Sundaram BM, Tippur HV (2016b) Dynamic crack growth normal to an interface in bi-layered materials: an experimental study using digital gradient sensing technique. Exp Mech 56(1):37–57. https://doi.org/10.1007/s11340-015-0029-x

Suresh S, Sugimura Y, Tschegg EK (1992) The growth of a fatigue crack approaching a perpendicularly-oriented, bimaterial interface. Scr Metall Mater 27(9):1189–1194. https://doi.org/10.1016/0956-716X(92)90597-8

Verlet L (1967) Computer" experiments" on classical fluids. I. Thermodynamical properties of Lennard-Jones molecules. Phys Rev 159(1):98. https://doi.org/10.1103/PhysRev.159.98

Wang L, Bobaru F (2021) Connections between the meshfree peridynamics discretization and graph Laplacian for transient diffusion problems. J Peridyn Nonlocal Model 3(4):307–326. https://doi.org/10.1007/s42102-021-00053-2

Wang L, Jafarzadeh S, Mousavi F, Bobaru F (2023) PeriFast/corrosion: a 3D pseudospectral peridynamic MATLAB code for corrosion. J Peridyn Nonlocal Model. https://doi.org/10.1007/s42102-023-00098-5

Wool RP (1995) Polymer Interfaces: Structure and Strength. Hanser Pub Inc, Cincinnati

Wu P, Yang F, Chen Z, Bobaru F (2021) Stochastically homogenized peridynamic model for dynamic fracture analysis of concrete. Eng Fract Mech 253(April):107863. https://doi.org/10.1016/j.engfracmech.2021.107863

Xu Z, Zhang G, Chen Z, Bobaru F (2018) Elastic vortices and thermally-driven cracks in brittle materials with peridynamics. Int J Fract 209(1–2):203–222. https://doi.org/10.1007/s10704-017-0256-5

Zhang Y, Qiao P (2019) A new bond failure criterion for ordinary state-based peridynamic mode II fracture analysis. Int J Fract 215(1–2):105–128. https://doi.org/10.1007/s10704-018-00341-x

Zhang G, Le Q, Loghin A, Subramaniyan A, Bobaru F (2016) Validation of a peridynamic model for fatigue cracking. Eng Fract Mech 162:76–94. https://doi.org/10.1016/j.engfracmech.2016.05.008

Zhang G, Gazonas GA, Bobaru F (2018) Supershear damage propagation and sub-Rayleigh crack growth from edge-on impact: A peridynamic analysis. Int J Impact Eng 113(April 2017):73–87. https://doi.org/10.1016/j.ijimpeng.2017.11.010

Zhao J, Chen Z, Mehrmashhadi J, Bobaru F (2020) A stochastic multiscale peridynamic model for corrosion-induced fracture in reinforced concrete. Eng Fract Mech. https://doi.org/10.1016/j.engfracmech.2020.106969

Zhou X, Wang Y, Shou Y, Kou M (2018) A novel conjugated bond linear elastic model in bond-based peridynamics for fracture problems under dynamic loads. Eng Fract Mech 188:151–183. https://doi.org/10.1016/j.engfracmech.2017.07.031

Zhu Q, Ni T (2017) Peridynamic formulations enriched with bond rotation effects. Int J Eng Sci 121:118–129. https://doi.org/10.1016/j.ijengsci.2017.09.004

Acknowledgements

This work has been supported by National Science Foundation under CDS&E CMMI Award No. 1953346. This work was completed utilizing the Holland Computing Center of the University of Nebraska, which receives support from the Nebraska Research Initiative.

Author information

Authors and Affiliations

Contributions

LW, JM, and FB developed the model and wrote the main manuscript text. LW and JM implemented the code and ran the computational simulations. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary file1 (mp4 1504 KB)

Supplementary file2 (mp4 1577 KB)

Supplementary file3 (mp4 5533 KB)

Supplementary file4 (mp4 7893 KB)

Supplementary file5 (mp4 664 KB)

Supplementary file6 (mp4 1611 KB)

Supplementary file7 (mp4 831 KB)

Supplementary file8 (mp4 2411 KB)

Supplementary file9 (mp4 6225 KB)

Supplementary file10 (mp4 3666 KB)

Supplementary file11 (mp4 1833 Kb)

Supplementary file12 (mp4 38626 Kb)

Appendix

Appendix

To demonstrate the criticality of each of the model components discussed in Sect. 4, we show from PD models that lack as least one of the essential components. We also show results from a PD model in which interface bonds are also softened, to mimic the potential sensitivity of the glue to rapidly propagating cracks.

1.1 Results from models missing at least one critical component

The PD model introduced in Section 4, three elements were called “critical”: (1) the HAZ that softens bonds around the crack tip to account for changes in PMMA mechanical properties due to heat generated by the rapidly propagating crack; (2) independent modes of fracture (mode I independent from mode II, achieved here by using a special case of a state-based model); and (3) a bi-linear model for bond-failure (bond-softening before final failure), capable to match both a given fracture toughness and the material strength, with any horizon size.

The influence of the HAZ has been studied in our previous study (Mehrmashhadi et al. 2019b). Without HAZ, the simulated crack propagation velocity in PMMA is around twice as fast as the experimentally measured values. In Fig. 21, we compare the crack propagation velocity in the case with the interface at 7mm.

Comparisons of crack propagation speed (PD models with and without HAZ) in the bi-layered PMMA with the interface location at 7 mm. Experimental results from Sundaram and Tippur (2016a)

Having independent modes of fracture (mode I independent from mode II) is also critical to accurately capturing the mode-II dominated fracture along the interface. In Fig. 22, we show the results from bond-based models in which the mode II fracture is not independent from mode I. We observe that for the cases with the interface located at 17 and 28 \(\mathrm{mm}\), the cracks do not branch at the interface, and do not run along the interface.

A bond-failure model that uses a sudden drop of bond force from its highest value to zero (a one-parameter bond-failure model) can only match, for a given horizon size, either the fracture toughness or the material strength. Using this model with a critical bond strain matched to the fracture toughness, for example, will match a material’s strength for a particular size of the PD horizon. That size, however, may turn out to be extremely small and thus not usable for practical computations. A two-parameter bond-failure model, however, can match both the fracture toughness and the material strength, for any horizon size [see (Niazi et al. 2020) for details]. Matching material strength is critical in obtaining crack initiation at the correct stress levels in samples in which there are no pre-cracks. This is exactly our case in which we have crack initiation at the interface (before the main crack arrives there) and crack initiation into the second PMMA layer. Simulation results from a model that uses a one-parameter bond-damage model instead of the bi-linear model used in the main text of the paper are shown in Fig. 23. While branching appears to happen at the interface for the 17, 28, and 42 mm, there is very little propagation along the interface.

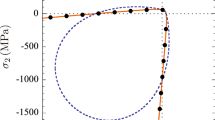

1.2 Results from model with heat-induced softening of interface bonds

While we do not have available data on the temperature variation of material properties for the glue material used in the PMMA bi-layered structure, it may be reasonable to assume a similar type of behavior as the HAZ model we used for PMMA. We therefore assume that interface bonds are affected by heat. In the model used here we do not include the independent modes of fracture (we use the bond-based model), nor the bi-linear bond-failure model. We hypothesize that the glue is more sensitive to the high temperatures caused by the rapid crack propagation, compared with PMMA. We use the bilinear model (pink dash line) shown in the figure below. The micromodulus of interface bonds decreases to 0.01 \({c}_{glue}\) when the bond strain is larger than 0.1 \({s}_{0}\) (Fig. 24).

The constitutive model for interface bonds in the HAZ is:

Similar to Eq. (37), to maintain the fracture energy \({G}_{0}\) the same, the following condition needs to be satisfied (areas under linear and bilinear functions need to match) for the interfacial bonds:

The critical strain \({s}_{glue-bi-0}\) for the bilinear function of interface bonds is 4.23 \({s}_{0}\).

With this model, the damage maps for PMMA samples with weak/strong interface and samples with different interface locations are shown below. The histories of the crack tip propagation speeds are compared with experiments as well. In Figs. 25 and 26, the crack path and crack velocity of PMMA samples with weak/strong interface match well with the experiments.

Comparisons between experimental results (from Sundaram and Tippur 2016b) and results obtained with the bond-based PD model with heat-induced softening of interface bonds for crack propagation speed in the bi-layered PMMA with: a strong interface, and b weak interface

However, since in the regular bond-based model (with one-parameter bond-failure model), the mode II fracture is not independent from mode I fracture, and the material strength will differ depending on the horizon size, mode II-dominated fracture and crack initiation along the interface are not going to be accurately captured. Indeed, as seen from Fig. 27, the crack lengths along the interface obtained by these simulations, especially when d = 42 mm, are significantly smaller compared with the experimental results (Sundaram and Tippur 2016a). Also, when d = 7 mm, the crack branches inside the second layer of PMMA, which is not observed in experiments (Sundaram and Tippur 2016a). Since the HAZ in PMMA is considered here, crack propagation speeds, shown in Figs. 26 and 28 are in good agreement with experiments.

Comparisons between experimental results (from Sundaram and Tippur 2016a) and results obtained with the bond-based PD model with heat-induced softening of interface bonds crack propagation speed in the bi-layered PMMA with the interface location at: a 7 mm, b 17 mm, and c 42 mm

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, L., Mehrmashhadi, J. & Bobaru, F. Interfaces in dynamic brittle fracture of PMMA: a peridynamic analysis. Int J Fract 244, 217–245 (2023). https://doi.org/10.1007/s10704-023-00731-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-023-00731-w