Abstract

Ring Brazilian disc specimens are favored for determining the tensile strength and mixed mode fracture toughness. To further understand the fracture mechanism of ring Brazilian disc specimens, the phase field method is used to investigate the cracking process and peak load of ring Brazilian disc specimens. First, the numerical validity and accuracy of the phase field method is verified by a benchmark example. Then, the effect of aperture ratio and crack inclination angle on the failure process and peak load of ring Brazilian disc specimens is studied. Finally, by combining the phase field method and J-integral method, the influence of prefabricated crack inclination angle and aperture ratios on mode I and II fracture toughness of cracked ring Brazilian disc specimens is discussed.

Similar content being viewed by others

Data availability

Data supporting this research article are available from the corresponding author via e-mail.

Abbreviations

- \(\Omega \) :

-

An arbitrary domain

- \(\partial \Omega \) :

-

External boundary

- \(\Gamma \) :

-

Internal discontinuity boundary

- \({\bar{\mathrm{u}}}\) :

-

Preserved displacement

- \(\partial \Omega _{\text {u}}\) :

-

Displacement boundary

- \({\bar{t}}\) :

-

Preserved traction

- \(\partial \Omega _{\text {t}}\) :

-

Traction boundary

- d :

-

Phase field

- \(\Pi \) :

-

Total potential energy

- \(\Pi ^{\text {int}}\) :

-

Internal potential energy

- \(\Pi ^{\text {ext}}\) :

-

External potential energy

- \(E ({\varvec{\varepsilon }}, d)\) :

-

Elastic energy

- W(d):

-

Fracture energy

- \(\psi ({\varvec{\varepsilon }})\) :

-

Elastic strain energy density function

- \(g_{\text {c}}\) :

-

Critical energy release rate

- \(l_{0}\) :

-

Length scale parameter

- \(\gamma (d, \nabla d)\) :

-

Crack surface density

- u :

-

Displacements vector

- \({\varvec{\varepsilon }}\) :

-

Strain tensor

- \({\varvec{\varepsilon }}^{+}\) :

-

Tensile strain tensor

- \({\varvec{\varepsilon }}^{-}\) :

-

Compressive strain tensor

- \(\varepsilon _{a}\) :

-

Principal strain

- \({{\varvec{n}}}_{a}\) :

-

Principal strain direction

- \(\psi ^{+}\) :

-

Elastic density caused by tension

- \(\psi ^{-}\) :

-

Elastic density caused by compression

- b :

-

Prescribed volume force

- \({\varvec{\sigma }}\) :

-

Cauchy stress tensor

- H :

-

History variable

- \(Y_{I}\) :

-

Mode I dimensionless SIF

- t :

-

Specimen thickness

- GFEM:

-

Generalized finite element method

- DDA:

-

Discontinuous deformation analysis

- DDM:

-

Displacement discontinuity method

- PFC:

-

Particle flow code

- PFM:

-

Phase field method

- SCB:

-

Notched semi- circular bending

- \({{\varvec{N}}}_{i}\) :

-

Shape function associated with the ith node

- \({\text {B}}_i^u\) :

-

Strain gradient matrix of the node i

- \({\text {B}}_i^d\) :

-

Cartesian derivative matrices of the node i

- \({{\varvec{R}}}^{\text {u}}\) :

-

Displacement residue vector

- \({{\varvec{R}}}^{\text {d}}\) :

-

Phase filed residue vector

- \(K_n^u\) :

-

Displacement tangent matrix

- \(K_n^d\) :

-

Phase field tangent matrix

- \({{\mathbb {D}}}\) :

-

Fourth-order elasticity tensor

- \({{\varvec{H}}}_{\upvarepsilon } (x)\) :

-

Heaviside function

- \({{\mathbb {P}}}^{\pm }\) :

-

Fourth-order projection tensor

- \({{\mathbb {J}}}\) :

-

Fourth-order tensor

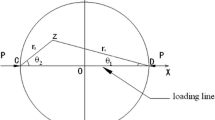

- R :

-

Radius of CCCD specimen

- 2a :

-

Crack length of CCCD specimen

- k :

-

Numerical smoothing coefficient

- \(\beta \) :

-

Crack inclination angles

- E :

-

Young’s modulus

- v :

-

Poisson’s ratio

- P :

-

Diametric concentrated forces

- \(R_{\text {i}}\) :

-

Inner diameter of ring Brazilian disc

- \(R_{\text {o}}\) :

-

Outer diameter of ring Brazilian disc

- \(\lambda \) :

-

Ratio of inner radius to outer radius

- \(P^{*}\) :

-

Dimensionless peak load

- a :

-

Fitting parameter

- b :

-

Fitting parameter

- c :

-

Fitting parameter

- \(K_{\text {Ic}}\) :

-

Mode I fracture toughness

- \(K_{\text {IIc}}\) :

-

Mode II fracture toughness

- SIFs:

-

Stress intensity factors

- \(Y_{II}\) :

-

Mode II dimensionless SIF

- XFEM:

-

Extended finite element method

- DEM:

-

Discrete element method

- PD:

-

Peridynamics

- GPD:

-

General particle dynamics

- CZM:

-

Cohesive zone model

- CCCD:

-

Centrally cracked circular disc

References

Akbardoost J, Ayatollahi MR, Aliha MRM, Pavier MJ, Smith DJ (2014) Size-dependent fracture behavior of Guiting limestone under mixed mode loading. Int J Rock Mech Min Sci 71:369–380

Akbardoost J, Ghadirian HR, Sangsefidi M (2017) Calculation of the crack tip parameters in the holed-cracked flattened Brazilian disk (HCFBD) specimens under wide range of mixed mode I/II loading. Fatigue Fract Eng Mater Struct 40(9):1416–1427

Aliha MRM, Ayatollahi MR, Pakzad R (2008) Brittle fracture analysis using a ring-shape specimen containing two angled cracks. Int J Fract 153(1):63

Aliha MRM, Ayatollahi MR, Smith DJ, Pavier MJ (2010) Geometry and size effects on fracture trajectory in a limestone rock under mixed mode loading. Eng Fract Mech 77(11):2200–2212

Aliha MRM, Ayatollahi MR, Akbardoost J (2012) Typical upper bound-lower bound mixed mode fracture resistance envelopes for rock material. Rock Mech Rock Eng 45(1):65–74

Aliha MRM, Ayatollahi MR (2013a) Two-parameter fracture analysis of SCB rock specimen under mixed mode loading. Eng Fract Mech 103:115–123

Aliha MRM, Hosseinpour GhR, Ayatollahi MR (2013b) Application of cracked triangular specimen subjected to three-point bending for investigating fracture behavior of rock materials. Rock Mech Rock Eng 46(5):1023–1034

Aliha MRM, Bahmani A, Akhondi Sh (2015) Determination of mode III fracture toughness for different materials using a new designed test configuration. Mater Design 86:863–871

Aliha MRM, Bahmani A, Akhondi Sh (2016a) A novel test specimen for investigating the mixed mode I+III fracture toughness of hot mix asphalt composites-Experimental and theoretical study. Int J Solids Struct 90:167–177

Aliha MRM, Bahmani A, Akhondi Sh (2016b) Mixed mode fracture toughness testing of PMMA with different three-point bend type specimens. Eur J Mech A-solid 58:148–162

Aliha MRM, Bahmani A (2017) Rock fracture toughness study under mixed mode I/III lloading. Rock Mech Rock Eng 50(7):1739–1751

Aliha MRM, Berto F, Mousavi A, Razavi SMJ (2017) On the applicability of ASED criterion for predicting mixed mode I+II fracture toughness results of a rock material. Theor Appl Fract Mec 92:198–204

Aliha MRM, Linul E, Bahmani A, Marsavina L (2018a) Experimental and theoretical fracture toughness investigation of PUR foams under mixed mode I+III loading. Polym Test 67:75–83

Aliha MRM, Mahdavi E, Ayatollahi MR (2018b) Statistical analysis of rock fracture toughness data obtained from different chevron notched and straight cracked mode I specimens. Rock Mech Rock Eng 51(7):2095–2114

Aliha MRM, Razmi A, Mousavi A (2018c) Fracture study of concrete composites with synthetic fibers additive under modes I and III using ENDB specimen. Constr Build Mater 190:612–622

Amrollahi H, Baghbanan A, Hashemolhosseini H (2011) Measuring fracture toughness of crystalline marbles under modes I and II and mixed mode I-II loading conditions using CCNBD and HCCD specimens. Int J Rock Mech Min Sci 48(7):1123–1134

Bai QS, Tu ST, Zhang C (2016) DEM investigation of the fracture mechanism of rock disc containing hole(s) and its influence on tensile strength. Theor Appl Fract Mech 86:197–216

Bi J, Zhou XP, Qian QH (2016) The 3D numerical simulation for the propagation process of multiple pre-existing flaws in rock-like materials subjected to biaxial compressive loads. Rock Mech Rock Eng 49(5):1611–1627

Bourdin B, Francfort GA, Marigo JJ (2000) Numerical experiments in revisited brittle fracture. J Mech Phys Solids 48(4):797–826

Bourdin B, Francfort GA, Marigo JJ (2008) The variational approach to fracture. J Elast 91(1):5–148

Carlsson J, Isaksson P (2019) Crack dynamics and crack tip shielding in a material containing pores analysed by a phase field method. Eng Fract Mech 206:526–540

Chang L, Jiang G (2019) Cracking simulation of asphalt concrete beam specimen using cohesive zone model. Constr Build Mater 214:49–60

Chen CH, Chen CS, Wu JH (2008) Fracture toughness analysis on cracked ring disks of anisotropic rock. Rock Mech Rock Eng 41(4):539–562

Chen CS, Hsu SC (2001) Measurement of indirect tensile strength of anisotropic rocks by the ring test. Rock Mech Rock Eng 34(4):293–321

Dai F, Wei MD, Xu NW, Ma Y, Yang DS (2015) Numerical assessment of the progressive rock fracture mechanism of cracked chevron notched Brazilian disc specimens. Rock Mech Rock Eng 48(2):463–479

Eftekhari M, Baghbanan A, Hashemolhosseini H (2015) Fracture propagation in a cracked semicircular bend specimen under mixed mode loading using extended finite element method. Arab J Geosci 8(11):9635–9646

Eftekhari M, Baghbanan A, Hashemolhosseini H, Amrollahi H (2015) Mechanism of fracture in macro- and micro-scales in hollow centre cracked disc specimen. J Cent South Univ 22:4426–4433

Erarslan N, Liang ZZ, Williams DJ (2012) Experimental and numerical studies on determination of indirect tensile strength of rocks. Rock Mech Rock Eng 45(5):739–751

Fries TP, Belytschko T (2010) The extended/generalized finite element method: an overview of the method and its applications. Int J Numer Methods Eng 84(3):253–304

Gürses E, Miehe C (2009) A computational framework of three-dimensional configurational-force-driven brittle crack propagation. Comput Meth Appl Mech Eng 198(15–16):1413–1428

Griffith AA (1921) The Phenomena of Rupture and Flow in Solids. Phil Trans R Soc Lond 221:163–198

Ghazvinian A, Nejati HR, Sarfarazi V, Hadei MR (2013) Mixed mode crack propagation in low brittle rock-like materials. Arab J Geosci 6(11):4435–4444

Haeri H, Khaloo A, Marji MF (2015) Fracture analyses of different pre-holed concrete specimens under compression. Acta Mech Sin 31(6):855–870

Hobbs DW (1965) An assessment of a technique for determining the tensile strength of rock. Brith J Appl Phys 16(2):259–268

Huang YH, Yang SQ (2014) Particle flow simulation of fracture characteristics and crack propagation mechanism of holed-cracked Brazilian disc specimen. Rock Soil Mech 35(8):2269–2285

Hudson JA (1969) Tensile strength and the ring test. Int J Rock Mech Min Sci Geomech Abstr 6(1):91–97

Ju MH, Li JC, Li XF, Zhao J (2019a) Fracture surface morphology of brittle geomaterials influenced by loading rate and grain size. Int J Impact Eng 133:103363

Ju MH, Li JC, Yao QL, Li XF, Zhao J (2019b) Rate effect on crack propagation measurement results with crack propagation gauge, digital image correlation, and visual methods. Eng Fract Mech 217:106537

Kourkoulis SK, Markides ChF (2014) Stresses and displacements in a circular ring under parabolic diametral compression. Int J Rock Mech Min Sci 71:272–292

Kourkoulis SK, Markides CF, Pasiou ED (2015) A combined analytic and experimental study of the displacement field in a circular ring. Meccanica 50(2):493–515

Li XB, Feng F, Li DY (2018) Numerical simulation of rock failure under static and dynamic loading by splitting test of circular ring. Eng Fract Mech 188:184–201

Li DY, Wang T, Cheng TJ, Sun XL (2016) Static and dynamic tensile failure characteristics of rock based on splitting test of circular ring. Trans Nonferrous Met Soc China 26(7):1912–1918

Liao ZY, Zhu JB, Tang CA (2019) Numerical investigation of rock tensile strength determined by direct tension, Brazilian and three-point bending tests. Int J Rock Mech Min Sci 115:21–32

Ma YF, Huang HY (2018) DEM analysis of failure mechanisms in the intact Brazilian test. Int J Rock Mech Min Sci 102:109–119

Mansourian A, Hashemi S, Aliha MRM (2018) Evaluation of pure and mixed modes (I/III) fracture toughness of Portland cement concrete mixtures containing reclaimed asphalt pavement. Constr Build Mater 178:10–18

Melro A, Camanho P, Pires FA, Pinho S (2013) Micromechanical analysis of polymer composites reinforced by unidirectional fbres: Part I-Constitutive modelling. Int J Solids Struct 50:1897–905

Meng T, Bao XK, Zhao JC, Hu YQ (2018) Study of mixed mode fracture toughness and fracture characteristic in gypsum rock under brine saturation. Environ Earth Sci 77:364–368

Miehe C, Hofacker M, Welschinger F (2010) A phase field model for rate-independent crack propagation: robust algorithmic implementation based on operator splits. Comput Meth Appl Mech Eng 199(45–48):2765–2778

Miehe C, Welschinger F, Hofacker M (2010) Thermodynamically consistent phase-field models of fracture: variational principles and multi-field fe implementations. Int J Numer Methods Eng 83(10):1273–311

Mirsayar MM, Berto F, Aliha MRM, Park P (2016) Strain-based criteria for mixed-mode fracture of polycrystalline graphite. Eng Fract Mech 156:114–123

Mirsayar MM, Razmi A, Aliha MRM, Berto F (2018) EMTSN criterion for evaluating mixed mode I/II crack propagation in rock materials. Eng Fract Mech 190:186–197

Molnár G, Gravouil A (2017) 2D and 3D Abaqus implementation of a robust staggered phase-field solution for modeling brittle fracture. Finite Elem Anal Des 130:27–38

Ning YJ, Yang J, An XM, Ma GW (2010) Modelling rock fracturing and blast induced rock mass failure via advanced discretisation within the discontinuous deformation analysis framework. Comput Geotech 38(1):40–9

Pakzad R, Ayatollahi MR (2016) A comprehensive study on crack tip parameters of modified ring specimen for mixed-mode fracture toughness tests on brittle materials. Geotech Test J 39(1):144–156

Patil RU, Mishra BK, Singh IV (2019) A multiscale framework based on phase field method and XFEM to simulate fracture in highly heterogeneous materials. Theor Appl Fract Mech 100:390–415

Rabczuk T, Zi G, Bordas S, Nguyen-Xuan H (2008) A geometrically non-linear three-dimensional cohesive crack method for reinforced concrete structures. Eng Fract Mech 75(16):4740–4758

Razavi SMJ, Aliha MRM, Berto F (2018) Application of an average strain energy density criterion to obtain the mixed mode fracture load of granite rock tested with the cracked asymmetric four-point bend specimens. Theor Appl Fract Mec 97:419–425

Tanné E, Li T, Bourdin B, Marigo JJ, Maurini C (2018) Crack nucleation in variational phase-field models of brittle fracture. J Mech Phys Solids 110:80–99

Tian WL, Yang SQ, Xie LX, Wang ZL (2018) Cracking behavior of three types granite with different grain size containing two non-coplanar fissures under uniaxial compression. Arch Civ Mech Eng 18(4):1580–1596

Vasarhelyi B, Bobet A (2000) Modeling of crack initiation, propagation and coalescence in uniaxial compression. Rock Mech Rock Eng 33(2):119–39

Wang LF, Zhou XP (2020) Phase field modelfor simulating the fracture behaviors of some disc-type specimens. Eng Fract Mech. https://doi.org/10.1016/j.engfracmech.2020.106870

Wang YT, Zhou XP, Kou MM (2019) An improved coupled thermo-mechanic bond-based peridynamic model for cracking behaviors in brittle solids subjected to thermal shocks. Eur J Mech A-Solids 73:282–305

Wang YT, Zhou XP, Xu X (2016) Numerical simulation of propagation and coalescence of flaws in rock materials under compressive loads using the extended non-ordinary state-based peridynamics. Eng Fract Mech 163:248–273

Wang YT, Zhou XP, Shou YD (2017) The modeling of crack propagation and coalescence in rocks under uniaxial compression using the novel conjugated bond-based peridynamics. Int J Mech Sci 128–129:614–643

Wu SC, Ma J, Cheng Y, Xu MF, Huang XQ (2018) Numerical analysis of the flattened Brazilian test: Failure process, recommended geometric parameters and loading conditions. Eng Fract Mech 204:288–305

Wu JY, Q JF, Nguyen VP, Mandal TK, Zhuang LJ (2019) Computational modeling of localized failure in solids: XFEM vs PF-CZM. Comput Meth Appl Mech Eng 345:618–643

Xie YS, Cao P, Jin J, Wang M (2017) Mixed mode fracture analysis of semi-circular bend (SCB) specimen: A numerical study based on extended finite element method. Comput. Geotech 82:157–172

Zhang YB, Liang ZZ, Tang SB, Jia JH (2012) Numerical simulation of ring-shape rock failure under compressive loading. Adv Mater Res 378–379:15–18

Zhou F, Molinari JF (2004) Dynamic crack propagation with cohesive elements: a methodology to address mesh dependency. Int J Numer Methods Eng 59(1):1–24

Zhou SW, Rabczuk T, Zhuang XY (2018a) Phase field modeling of quasi-static and dynamic crack propagation: COMSOL implementation and case studies. Adv Eng Softw 122:31–49

Zhou SW, Xia CC (2018b) Propagation and coalescence of quasi-static cracks in Brazilian disks: an insight from a phase field model. Acta Geotech 14(4):1195–1214

Zhou SW, Zhuang XY (2018c) Adaptive phase field simulation of quasi-static crack propagation in rocks. Undergr Space 3(3):190–205

Zhou XP, Bi J, Qian QH (2015) Numerical simulation of crack growth and coalescence in rock-like materials containing multiple pre-existing flaws. Rock Mech Rock Eng 48(3):1097–114

Zhou XP, Wang LF, Berto F, Zhou LS (2019) Comprehensive study on the crack tip parameters of two types of disc specimens under combined confining pressure and diametric concentrated forces. Theor Appl Fract Mech 103:102317

Zhou XP, Wang YT (2016) Numerical simulation of crack propagation and coalescence in pre-cracked rock-like Brazilian disks using the non-ordinary state-based peridynamics. Int J Mech Sci 89:235–249

Acknowledgements

The work is supported by the National Natural Science Foundation of China (Nos. 51839009 and 51679017).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhou, X., Wang, L. & Shou, Y. Understanding the fracture mechanism of ring Brazilian disc specimens by the phase field method. Int J Fract 226, 17–43 (2020). https://doi.org/10.1007/s10704-020-00476-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-020-00476-w