Abstract

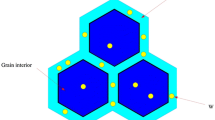

This work examines the influence of changes in grain boundary (GB) strength on microstructure dependent crack propagation in polycrystalline tungsten (W). The property of focus is brittleness index (BI) originally introduced by Evans and Marshall in 1976 and 1979, respectively, used in order to quantify the extent of brittleness of a material. In an earlier work, GBs of Ni-doped polycrystalline W have been characterized for embrittlement using ab-initio quantum mechanical simulations as a function of Ni atomic volume fraction and GB thickness. This work focuses on quantifying the influence of GB strength on microstructure dependent crack propagation. Continuum mechanical GB strength properties and effective W grain properties are derived from ab-initio simulation based stress–strain curves. The crack propagation simulations when GBs are considered of finite width are based on an extended finite element (XFEM) framework. Simulations that consider GBs of infinitesimal width due to mesh resolution issues are based on a combined XFEM-cohesive finite element model that employs cohesive elements at GBs. Analyses of crack propagation through finite width GBs focus on understanding the role of square root of length scale dimension in the original BI formulation. Based on analyses of crack propagation through finite width GBs oriented at angles varying from \(0^{\circ }\,\hbox {to}\,90^{\circ }\) with respect to advancing crack, a quantitative criterion based on a failure index which predicts crack propagation path in polycrystalline W is proposed and examined.

Similar content being viewed by others

References

ABAQUS Users Manual (2010) V. 6.10-1. Dassault Systemes Simulia Corp., Providence

Agah-Tehrani A, Lee EH, Mallett RL, Onat ET (1987) The theory of elastic-plastic deformation at finite strain with induced anisotropy modeled as combined isotropic-kinematic hardening. J Mech Phys Solids 35(5):519–539

ASM International (1986) Guide to materials engineering data and information. ASM International, Metals Park

ASTM-E1823 (1996) Standard terminology relating to fatigue and fracture testing. ASTM International, West Conshohocken

ASTM-E399 (1997) Standard test method for plane-strain fracture toughness of metallic materials. Annu Book ASTM Stand 3:485–451

Atluri S, Kobayashi A, Nakagaki M (1975) An assumed displacement hybrid finite element model for linear fracture mechanics. Int J Fract 11(2):257–271

Bartolucci S, Schlössin HH (1966) Plastic deformation preceding fracture in tungsten Carbide–Cobalt alloys. Acta Metall 14(3):337–339

Bažant ZP, Estenssoro LF (1979) Surface singularity and crack propagation. Int J Solids Struct 15(5):405–426

Belytschko T, Black T (1999) Elastic crack growth in finite elements with minimal remeshing. Int J Numer Methods Eng 45(5):601–620

Benthem JP (1977) State of stress at the vertex of a quarter-infinite crack in a half-space. Int J Solids Struct 13(5):479–492

Benzeggagh ML, Kenane M (1996) Measurement of mixed-mode delamination fracture toughness of unidirectional glass/epoxy composites with mixed-mode bending apparatus. Compos Sci Technol 56(4):439–449

Benzley SE (1974) Representation of singularities with isoparametric finite elements. Int J Numer Methods Eng 8(3):537–545

Bittencourt TN, Wawrzynek PA, Ingraffea AR, Sousa JL (1996) Quasi-automatic simulation of crack propagation for 2D LEFM problems. Eng Fract Mech 55(2):321–334

Cartwright D, Rooke D (1975) Evaluation of stress intensity factors. J Strain Anal Eng Des 10(4):217–224

Cermelli P, Fried E, Sellers S (2001) Configurational stress, yield and flow in rate–independent plasticity. Proc R Soc Lond Ser A Math Phys Eng Sci 457(2010):1447–1467

Dolbow J, Moës N, Belytschko T (2000) Discontinuous enrichment in finite elements with a partition of unity method. Finite Elem Anal Des 36(3–4):235–260

Dolbow J, Moës N, Belytschko T (2001) An extended finite element method for modeling crack growth with frictional contact. Comput Methods Appl Mech Eng 190(51–52):6825–6846

Erdogan F, Sih G (1963) On the crack extension in plates under plane loading and transverse shear. J Basic Eng 85:519

Evans AG, Wilshaw TR (1976) Quasi-static solid particle damage in brittle solids: I. Acta Metall 24(10):939–956

Gludovatz B, Wurster S, Hoffmann A, Pippan R (2010) Fracture toughness of polycrystalline tungsten alloys. Int J Refract Metals Hard Mater 28(6):674–678

Gravouil A, Moës N, Belytschko T (2002) Non-planar 3D crack growth by the extended finite element and level sets—part II: level set update. Int J Numer Methods Eng 53(11):2569–2586

Gumbsch P (2003) Brittle fracture and the brittle-to-ductile transition of tungsten. J Nucl Mater 323(2–3):304–312

Guo X, Leung AYT, He XQ, Jiang H, Huang Y (2008) Bending buckling of single-walled carbon nanotubes by atomic-scale finite element. Compos Part B Eng 39:202–208

Gupta VK, Yoon D-H, Meyer Iii HM, Luo J (2007) Thin intergranular films and solid-state activated sintering in nickel-doped tungsten. Acta Mater 55(9):3131–3142

Huang R, Sukumar N, Prévost JH (2003) Modeling quasi-static crack growth with the extended finite element method part II: numerical applications. Int J Solids Struct 40(26):7539–7552

Irwin GR (1957) Analysis of stresses and strains near the end of a crack traversing a plate. J Appl Mech 24:361–364

Kong X, Qiao Y (2005) Crack trapping effect of persistent grain boundary islands. Fatigue Fract Eng Mater Struct 28(9):753–758

Krasko GL (1993) Effect of impurities on the electronic structure of grain boundaries and intergranular cohesion in tungsten. Int J Refract Metals Hard Mater 12(5):251–260

Lawn BR, Marshall DB (1979) Hardness, toughness, and brittleness: an indentation analysis. J Am Ceram Soc 62(7–8):347–350

Lee EH (1969) Elastic–plastic deformation at finite strains. J Appl Mech 36(1):1–6

Lee H, Tomar V (2012) Understanding effect of grain boundaries in the fracture behavior of polycrystalline tungsten under mode-I loading. ASME J Eng Mater Technol 134(3):031010

Lee H, Tomar V (2013) An examination of nickel doping effect on the mechanical strength of a tungsten grain boundary. Comput Mater Sci 77:131–138

Lee H, Tomar V (2014) Understanding the influence of grain boundary thickness variation on the mechanical strength of a nickel-doped tungsten grain boundary. Int J Plast 53:135–147

Liu XY, Xiao QZ, Karihaloo BL (2004) XFEM for direct evaluation of mixed mode SIFs in homogeneous and bi-materials. Int J Numer Methods Eng 59(8):1103–1118

Luo J, Gupta VK, Yoon DH, Meyer HM III (2005) Segregation-induced grain boundary premelting in nickel-doped tungsten. Appl Phys Lett 87(23):231902–231903

Mai Y-W, Lawn BR (1987) Crack-interface grain bridging as a fracture resistance mechanism in ceramics: II, theoretical fracture mechanics model. J Am Ceram Soc 70(4):289–294

Margevicius RW, Riedle J, Gumbsch P (1999) Fracture toughness of polycrystalline tungsten under mode I and mixed mode I/II loading. Mater Sci Eng A 270(2):197–209

Moës N, Dolbow J, Belytschko T (1999) A finite element method for crack growth without remeshing. Int J Numer Methods Eng 46(1):131–150

Moës N, Gravouil A, Belytschko T (2002) Non-planar 3D crack growth by the extended finite element and level sets—part I: mechanical model. Int J Numer Methods Eng 53(11):2549–2568

Nash Gifford L Jr, Hilton PD (1978) Stress intensity factors by enriched finite elements. Eng Fract Mech 10(3):485–496

Natarajan S, Mahapatra DR, Bordas SPA (2010) Integrating strong and weak discontinuities without integration subcells and example applications in an XFEM/GFEM framework. Int J Numer Methods Eng 83(3):269–294

Nuismer RJ (1975) An energy release rate criterion for mixed mode fracture. Int J Fract 11(2):245–250

Ramasubramanian PV, Stein DF (1973) An investigation of grain-boundary embrittlement in Fe–P, Fe–P–S, and Fe–Sb–S alloys. Metall Trans 4(7):1735–1742

Ray A, Mukherjee D, Sarkar B, Mishra S (1994) Influence of microstructure on the premature failure of a second-intermediate sendzimir mill drive roll. J Mater Eng Perform 3(5):649–656

Rice JR (1968) A path independent integral and the approximate analysis of strain concentration by notches and cracks. J Appl Mech 35:379–386

Rooke DP, Cartwright DJ, Britain G (1976) Compendium of stress intensity factors

Rooke DP, Baratta FI, Cartwright DJ (1981) Simple methods of determining stress intensity factors. Eng Fract Mech 14(2):397–426

Sato K, Miyazaki H, Ikuhara Y, Kurishita H, Yoshinaga H (1990) Structure and strength of grain-boundaries in si bicrystals with \(<1{\rm H}>\) twist misorientations. Mater Trans JIM 31(10):865–872

Sih GC (1974) Strain-energy-density factor applied to mixed mode crack problems. Int J Fract 10(3):305–321

Steinmann P, Ackermann D, Barth FJ (2001) Application of material forces to hyperelastostatic fracture mechanics. II. Computational setting. Int J Solids Struct 38(32–33):5509–5526

Sukumar N, Moës N, Moran B, Belytschko T (2000) Extended finite element method for three-dimensional crack modelling. Int J Numer Methods Eng 48(11):1549–1570

Sukumar N, Prévost JH (2003) Modeling quasi-static crack growth with the extended finite element method part I: computer implementation. Int J Solids Struct 40(26):7513–7537

Takasugi T, Izumi O (1985) Electronic and structural studies of grain boundary strength and fracture in L12 ordered alloys–I. On binary A3B alloys. Acta Metall 33(7):1247–1258

Tamaki J, Zhang Z, Fujimori K, Akiyama M, Harada T, Miura N, Yamazoe N (1994) Grain-size effects in tungsten oxide-based sensor for nitrogen oxides. J Electrochem Soc 141(8):2207–2210

Tomar V, Zhai J, Zhou M (2004) Bounds on element size in a variable stiffness cohesive finite element method. Int J Numer Methods Eng 61:1894–1920

Watanabe T, Tsurekawa S (1999) The control of brittleness and development of desirable mechanical properties in polycrystalline systems by grain boundary engineering. Acta Mater 47(15–16):4171–4185

Weber GG, Lush AM, Zavaliangos A, Anand L (1990) An objective time-integration procedure for isotropic rate-independent and rate-dependent elastic-plastic constitutive equations. Int J Plast 6(6):701–744

Wei Q, Jiao T, Ramesh KT, Ma E, Kecskes LJ, Magness L, Dowding R, Kazykhanov VU, Valiev RZ (2006) Mechanical behavior and dynamic failure of high-strength ultrafine grained tungsten under uniaxial compression. Acta Mater 54(1):77–87

Westbrook J, Wood D (1961) Embrittlement of grain boundaries by equilibrium segregation. Nature 192:1280–1281

Zhu X-K, Joyce JA (2012) Review of fracture toughness (G, K, J, CTOD, CTOA) testing and standardization. Eng Fract Mech 85:1–46

Zurek AK, Gray GT III (1991) Dynamic strength and strain rate effects on fracture behavior of tungsten and tungsten alloys. Le J Phys IV 1(C3):C3-631–C3-637

Acknowledgments

This work is partially supported by a DoE-NETL Grant DEFE0011291 (Hongsuk Lee) and an US-AFoSR Grant FA9550-15-1-0202 (Program Manager Dr. Jennifer Jordon) (Chandra Prakash).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Prakash, C., Lee, H., Alucozai, M. et al. An analysis of the influence of grain boundary strength on microstructure dependent fracture in polycrystalline tungsten. Int J Fract 199, 1–20 (2016). https://doi.org/10.1007/s10704-016-0083-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-016-0083-0