Abstract

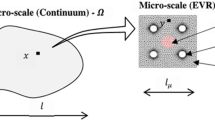

A three-dimensional unit cell model with an inclusion is established, where an interfacial layer between the matrix and inclusion is modeled by a cohesive zone mode. This model is then used to investigate the effect of the stress state of the unit cell on the crack nucleation at the interface and subsequently the void growth, which gives the evolutions of the macro equivalent stress and relative void volume fraction associated with the macro equivalent strain. The interface debonding process indicates that both the stress triaxility and the Lode parameter play a remarkable role in the process and void nucleation and growth. Compared with the model of pure void, the inclusion increases the load carrying capacity and lowers the void growth rate for the same stress triaxiality. Meanwhile the inclusion causes a lag in the expansion of the void due to the interface fracture, which becomes significant as the stress triaxiality increases. The interfacial crack nucleates from different position for different Lode parameter and propagates in different pattern as the Lode parameter changes the principal stresses even for the same stress triaxiality. The two points, where the crack initiates and where the interface is fully debonded, vary with stress triaxiality and Lode parameter, and are getting closer for different Lode parameters when stress triaxiality increases.

Similar content being viewed by others

References

Barrenblatt GI (1962) The mathematical theory of equilibrium cracks in brittle fracture. Adv Appl Mech 7:55–125

Camacho GT, Ortiz M (1996) Computational modelling of impact damage in brittle materials. Int J Solids Struct 33:2899–2938

Chang YW, Asaro RJ (1978) Bauschinger effects and work-hardening in spheroidized steels. Metal Sci 12:277–284

de-Andrés A, Pérez JL, Ortiz M (1999) Elastoplastic finite element analysis of three-dimensional fatigue crack growth in aluminum shafts subjected to axial loading. Int J Solids Struct 36:2231–2258

Dugdale DS (1960) Yielding of steel sheets containing slits. J Mech Phys Solids 8:100–108

Gall K, Horstemeyer MF, Degner BW, McDowell DL, Fan JH (2001) On the driving force for fatigue crack formation from inclusions and voids in a cast A356 aluminum alloy. Int J Fract 108:207–233

Galvez JC, Cendon DA, Planas J (2002) Influence of shear parameters on mixed-mode fracture of concrete. Int J Fract 118:163–189

Garrison WM, Wojcieszynski AL (2009) A discussion of the spacing of inclusions in the volume and of the spacing of inclusion nucleated voids on fracture surfaces of steels. Mater Sci Eng A 505:52–61

Hermes FH (2010) Process zone and cohesive element size in numerical simulation of delamination in bi-layers, In: Deparment of mechanical engineering 2010, Eindhoven University of Technology, Eindhoven

Keer LM, Dundurs J, Kiattikomol K (1973) Separation of a smooth circular inclusion from a matrix. Int J Eng Sci 11:1221–1233

Kim J, Gao X, Srivatsan TS (2004) Modeling of void growth in ductile solids: effects fo stress triaxiality and initial porosity. Eng Fract Mech 71:379–400

Koplik J, Needleman A (1988) Void growth and coalescence in porous plastic solids. Int J Solids Struct 24:835–853

Koplik J, Needleman A (1988) Void growth and coalescence in porous plastic solids. Int J Solids Struct 24:835–853

Kuna M, Sun DZ (1996) Three-dimensional cell model analyses of void growth in ductile materials. Int J Fract 81:235–258

Landron C, Bouaziz O, Maire E, Adrien J (2010) Characterization and modeling of void nucleation by interface decohesion in dual phase steels. Scr. Mater. 63:973–976

Legarth BN (2005) Effects of geometrical anisotropy on failure in a plastically anisotropic metal. Eng Fract Mech 72:2792–2807

McDowell DL, Gall K, Horstemeyer MF, Fan J (2003) Micro structure-based fatigue modeling of cast A356–T6 alloy. Eng Fract Mech 70:49–80

MSC.Software Corporation (2005) MSC.MARC 2005r3, volume A: theory and user information

Needleman A, Rice JR (1978) Limits to ductility set by plastic flow localization. In: Koistinen DP, Wang N-M (eds) Mechanics of sheet metal forming. Plenum Press, New York, pp 237–265

Needleman A (1987) A continuum model for void nucleation by inclusion debonding. J Appl Mech T ASME 54:525–531

Pessard E, Morel F, Morel A, Bellett D (2011) Modelling the role of non-metallic inclusions on the anisotropic fatigue behaviour of forged steel. Int J Fatigue 33:568–577

Prasannavenkatesan R, Zhang J, McDowell DL, Olson GB, Jou H-J (2009) 3D modeling of subsurface fatigue crack nucleation potency of primary inclusions in heat treated and shot peened martensitic gear steels. Int J Fatigue 31:1176–1189

Qian J, Li SF (2011) Application of multiscale cohesive zone model to simulate fracture in polycrystalline solids. J Eng Mater T ASME 133:011010

Qian GA, Zhou CE, Hong YS (2011) Experimental and theoretical investigation of environmental media on very-high-cycle fatigue behavior for a structural steel. Acta Mater 59:1321–1327

Scheider I, Brocks W (2003) Simulation of cup-cone fracture using the cohesive model. Eng Fract Mech 70:1943–1961

Shabrov MN, Needleman A (2002) An analysis of inclusion morphology effects on void nucleation. Model Simul Mater Sci 10:163–183

Shenoy MM, Kumar RS, McDowell DL (2005) Modeling effects of nonmetallic inclusions on LCF in DS nickel-base superalloys. Int J Fatigue 27:113–127

Taya M, Patterson W (1982) Growth of a debonded void at a rigid secondary particle in a viscous metal. J Mater Sci 17:115–120

Tvergaard V, Hutchinson JW (2008) Mode III effects on interface delamination. J Mech Phys Solids 56:215–229

Tvergaard V (2008) Effect of T-stress on crack growth under mixed mode I–III loading. Int J Solids Struct 45:5181–5188

Tvergaard V (2010) Effect of pure mode I, II or III loading or mode mixity on crack growth in a homogeneous solid. Int J Solids Struct 47:1611–1617

Xu XP, Needleman A (1993) Voin nucleation by inclusion debonding in a crystal matrix. Model Simul Mater Sci 1:111–132

Xue Y, McDowell DL, Horstemeyer MF, Dale MH, Jordon JB (2007) Micro structure-based multistage fatigue modeling of aluminum alloy 7075–T651. Eng Fract Mech 74:2810–2823

Yu QM, Hou NX, Yue ZF (2010) Finite element analysis of void growth behavior in nickel-based single crystal superalloys. Comput Mater Sci 48:597–608

Zhang KS, Bai JB, Francois D (2001) Numerical analysis of the influence of the Lode parameter on void growth. Int J Solids Struct 38:5847–5856

Acknowledgments

This work is supported by National Natural Science Foundation of China (11272260) and the Fundamental Research Funds for the Central Universities (3102015ZY031).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, Q.M. Influence of the stress state on void nucleation and subsequent growth around inclusion in ductile material. Int J Fract 193, 43–57 (2015). https://doi.org/10.1007/s10704-015-0016-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-015-0016-3