Abstract

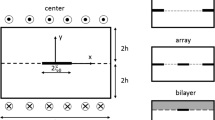

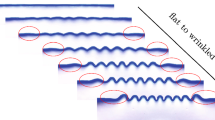

A thin skin of low tensile failure strain, if bonded to the tensile surface of an un-notched impact bend specimen of much tougher material, can change the global failure mode from ductile to brittle. A novel model of this well-known effect is developed and applied to results from impact tests on a tough core of polyamide-polyethylene blend, with a single skin of brittle EVOH. At a fixed crosshead speed, notched specimens of the blend become brittle at a relatively low temperature T bt. Un-notched bilayer specimens continue to show skin fracture up to a considerably higher temperature T fs; above this temperature they do not fail at all but below T bt they too fail in a brittle manner. Within the temperature range from T fs down to T bt there is a transition from crack arrest, either at the skin/core interface or further into the core where a crack would not normally propagate, to brittle fracture. This brittle fracture temperature is predicted by modelling the process as a three-phase impact event. In the first phase, the striker bends the bilayer quasi-statically. The second phase begins with instantaneous fracture of the skin at its failure strain. The skin ends retract at finite speed, and a craze grows in the adjacent core material to accommodate the local strain singularity. The last phase is a striker-driven impact event similar to that in a notched bend specimen of the core material, except that the crack-tip craze already bears the adiabatic temperature distribution generated while it was driven open by skin retraction. The criterion for craze decohesion, and hence for a crack jump, is the same adiabatic decohesion criterion which accounts for the speed-dependence of impact fracture in notched monolayer specimens. Applied computationally, this model predicts whether a bilayer structure fails in a brittle way or whether cracks initiated in the skin are arrested, either temporarily or permanently, at the skin/core interface.

Similar content being viewed by others

Abbreviations

- β :

-

Thermomechanical efficiency

- ΔH f :

-

Latent heat of fusion

- δ :

-

Crack tip opening displacement (COD)

- δ F :

-

COD at end of skin retraction

- δ r :

-

COD under remote loading

- δ u :

-

COD under uniform cohesive stress

- \({\dot{\delta}}\) :

-

Crack tip opening rate

- \({\dot{\delta}_0}\) :

-

Initial COD rate during skin retraction

- \({\epsilon_{\rm fs}}\) :

-

Failure strain

- κ :

-

Thermal diffusivity

- λ F :

-

Fibril draw ratio

- ρ :

-

Mass density

- ρ*:

-

Relative craze density

- σ c :

-

Cohesive stress or craze stress

- σ r :

-

Remote stress

- σ u :

-

Uniform normal cohesive traction

- a :

-

Crack length

- B :

-

Thickness of a TPB specimen

- C :

-

Load point compliance

- c :

-

Craze length

- C*:

-

Non-dimensional compliance

- c 0 :

-

Longitudinal wave speed

- C p :

-

Specific heat

- d :

-

Displacement of the striker on a TPB specimen

- E :

-

Young’s modulus

- E sec :

-

Secant modulus

- F :

-

Load measured during a TPB test

- h :

-

Surface heat transfer coefficient

- j :

-

Finite volume cell number

- k :

-

Thermal conductivity

- K Ir :

-

Stress intensity factor under remote loading

- K Iu :

-

Stress intensity factor under uniform cohesive stress

- L :

-

Length of a TPB specimen

- L 0 :

-

Cell size of finite volume model

- \({\dot{q^{\prime\prime}}}\) :

-

Rate of heat generated per unit area

- r(a):

-

Geometry function of stress intensity factor under remote loading

- S :

-

Span of a TPB specimen

- s :

-

Skin thickness of a bilayer specimen

- s c :

-

Critical thickness of the melt layer in the adiabatic decohesion model

- T :

-

Temperature

- t :

-

Time

- T 0 :

-

Initial test temperature

- T bts :

-

Transition temperature of a bilayer structures

- T bt :

-

Brittle/tough transition temperature

- t dc :

-

Failure time predicted by the adiabatic decohesion model

- T fs :

-

Temperature of failure of the skin of a bilayer structure

- T m :

-

Melting temperature

- u(c,a):

-

Geometry function of stress intensity factor under uniform cohesive stress

- W :

-

Width of a TPB specimen

- Fo :

-

Fourier number

References

Andersons J, Modniks J, Leterrier Y, Tornare G, Dumont P, Månsons J-AE (2008) Evaluation of toughness by finite fracture mechanics from crack onset strain of brittle coatings on polymers. Theor Appl Fract Mech 49: 151–157

Cudré-Mauroux N, Kausch HH, Cantwell WJ, Roulin-Moloney AC (1991) High speed crack propagation in bi-phase materials: an experimental study. Int J Fract 50(1): 67–77

Djiauw LK, Fesko DG (1976) Elongation of painted high-modulus elastomers at low temperatures. Rubber Chem Technol 49: 1111

Godovsky YK (1992) Thermophysical properties of polymers. Springer-Verlag, Berlin

Hayes DJ, Williams JG (1972) A practical method for determining Dugdale model solutions for cracked bodies of arbitrary shape. Int J Fract Mech 8(3): 239–256

Ivankovic A, Williams JG (1993) A local modulus analysis of rapid crack propagation in polymers. Int J Fract 64(4): 251–268

Kim SR, Nairn JA (2000) Fracture mechanics analysis of coating/substrate systems. Part I: analysis of tensile and bending experiments. Eng Fract Mech 65(5): 573–593

Könczöl L, Döll W, Ediger B (1991) On the mechanisms of surface embrittlement of ductile thermoplastics by brittle surface layers. Paper presented at the 8th Deformation, Yield and Fracture of Polymers conference, Cambridge

Leevers PS (1995) Impact and dynamic fracture of tough polymers by thermal decohesion in a Dugdale zone. Int J Fract 73(2): 109–127

Leevers PS, Godart MA (2008) Adiabatic decohesion in thermoplastic craze thickening at constant or increasing rate. J Mech Phys Solids 56: 2149–2170

Leevers PS, Morgan RE (1995) Impact fracture of polyethylene: a non-linear-elastic thermal decohesion model. Eng Fract Mech 52(6): 999–1014

Romeo A, Ballarini R (1997) A cohesive zone model for cracks terminating at a bimaterial interface. Int J Solids Struct 34(11): 1307–1326

Schoolenberg GE, Meijer HDF (1991) Ultra-violet degradation of polypropylene: 2. Residual strength and failure mode in relation to the degraded surface layer. Polymer 32(3): 438–444

So P, Broutman LJ (1982) The effect of surface embrittlement on the mechanical behavior of rubber-modified polymers. Polym Eng Sci 22(14): 888–894

Theocaris PS, Milios J (1981) Crack-arrest at a bimaterial interface. Int J Solids Struct 17(2): 217–230

Verpy C, Gacougnolle JL, Dragon A, Vanlerberghe A, Chesneau A, Cozette F (1994) The surface embrittlement of a ductile blend due to a brittle paint layer. Prog Org Coatings 24(1–4): 115–129

Wappling D, Gunnars J, Ståhle P (1998) Crack growth across a strength mismatched bimaterial interface. Int J Fract 89: 223–243

Zak AR, Williams ML (1963) Crack point singularities at a bimaterial interface. J Appl Mech 30: 142–143

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Godart, MA., Leevers, P. Effect of skin fracture on failure of a bilayer polymer structure. Int J Fract 148, 315–329 (2007). https://doi.org/10.1007/s10704-008-9204-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-008-9204-8