Abstract

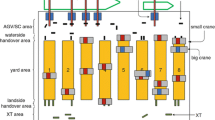

Loading of containers onto a vessel can be delayed if the containers are inappropriately stacked at the yard. Remarshaling is the preparatory task of rearranging the containers ahead of loading time to minimize the delay at the time of loading. Previous works on remarshaling derive a remarshaling plan assuming that a certain amount of continuous period of time is available for the remarshaling jobs to be done in a batch; remarshaling jobs cannot be mixed together with the current main jobs in the crane schedule. In contrast, the method proposed in this paper allows remarshaling jobs to be scheduled together with the current jobs under the framework of iterative rescheduling, in which scheduling and execution of the jobs within a predetermined fixed-length look-ahead horizon are repeated in a regular interval. The remarshaling jobs selected for the mix are those that contribute the most to the reduction of future loading delay. The number of remarshaling jobs and their temporal positions within the mixed schedule for a look-ahead horizon are determined appropriately to best utilize the idle time of the automated cranes, which is enforced by an objective function to minimize the delay of the current main jobs as well as the makespan of all the jobs in the horizon.

Similar content being viewed by others

References

Ahn EY, Park K, Kang B, Ryu KR (2007) Real time scheduling by coordination for optimizing operations of equipments in a container terminal. In: Proceedings of the 19th IEEE international conference on tools with artificial intelligence (ICTAI2007), Patras, Greece, Oct 2007, pp 44–48

Choe R, Park T, Oh M, Kang J, Ryu KR (2011) Generating a rehandling-free intra-block remarshaling plan for an automated container yard. J Intell Manuf 22(2):201–217

Choe R, Yuan H, Yang Y, Ryu KR (2012) Real-time scheduling of twin stacking cranes in an automated container terminal using a genetic algorithm. In: Proceedings of the 27th Annual ACM symposium on applied computing (ACM SAC 2012), Riva del Garda, Italy, March 2012, pp 238–243

Hirashima Y, Ishikawa N, Takeda K (2006) A new reinforcement learning for group-based marshalling plan considering desired layout of containers in port Terminals. In Proceedings of the 2006 IEEE conference on networking, sensing and control (ICNSC 2006), Ft. Lauderdale, FL, USA, April 2006, pp 670–675

Jang H, Choe R, Ryu KR (2012) Deriving a robust policy for container stacking using a noise-tolerant genetic algorithm. In: Proceedings of the 2012 ACM research in applied computation symposium (ACM RACS 2012), San Antonio, TX, USA, Oct 2012, pp 31–36

Jung SH, Kim KH (2006) Load scheduling for multiple quay cranes in port container terminals. J Intell Manuf 17:479–492

Kang J, Oh MS, Ahn EY, Ryu KR, Kim KH (2006) Planning for intra-block remarshalling in a container terminal. Adv Appl Artif Intell LNCS 4031:1211–1220

Kim KH, Bae JW (1998) Re-marshalling export containers in port container terminals. Comput Ind Eng 35:655–658

Kim KH, Hong GP (2006) A heuristic rule for relocating blocks. Comput Oper Res 33:940–954

Kim KY, Kim KH (1999) An optimal routing algorithm for a transfer crane in port container terminal. Transp Sci 33(1):17–33

Kim KY, Kim KH (2003) Heuristic algorithm for routing yard-side equipment for minimizing loading times in container terminals. Nav Res Logist 50:498–514

Kim KH, Kang JS, Ryu KR (2004) A beam search algorithm for the load sequencing of export containers in port container terminals. OR Spectr 26:93–116

Kozan E, Preston P (1999) Genetic algorithms to schedule container transfers at multimodal terminals. Int Trans Oper Res 6:311–329

Lee Y, Hsu NY (2007) An optimization model for the container pre-marshalling problem. Comput Oper Res 34(11):3295–3313

Lee DH, Cao Z, Meng Q (2007) Scheduling of two-transtainer systems for loading export containers in port container terminals with simulated annealing algorithm. Int J Prod Econ 107:115–124

Narasimhan A, Palekar US (2002) Analysis and algorithms for the transtainer routing problem in container port operations. Transp Sci 36:63–78

Ng WC (2005) Crane scheduling in container yards with inter-crane interference. Eur J Oper Res 164:64–78

Ng WC, Mak KL (2005a) Yard crane scheduling in port container terminals. J Appl Math Model 29:263–276

Ng WC, Mak KL (2005b) An effective heuristic for scheduling a yard crane to handle jobs with different ready times. J Eng Optim 37:867–877

Park K, Park T, Ryu KR (2009) Planning for remarshaling in an automated container terminal using cooperative coevolutionary algorithms. In: Proceedings of ACM symposium on applied computing (ACM SAC 2009), Honolulu, HI, USA, March 2009, pp 1098–1105

Park T, Choe R, Ok SM, Ryu KR (2010a) Real-time scheduling for twin ASCs in an automated container. OR Spectr 32:593–615

Park T, Kim J, Ryu KR (2010b) Iterative replanning using genetic algorithms for remarshaling in a container terminal. In: Proceedings of IASTED international conference on artificial intelligence and applications (AIA 2010), Innsbruck, Austria, Feb 2010, in CD

Park T, Sohn M, and Ryu KR (2010c) Optimizing stacking policies using an MOEA for an automated container terminal. In: Proceedings of the 40th international conference on computers and industrial engineering (CIE), pp 1–6

Park K, Park T, Ryu KR (2013) Planning for selective remarshaling in an automated container terminal using coevolutionary algorithms. Int J Ind Eng Theory Appl Pract 20:176–187

Parragh SN, Doerner KF, Hartl RF (2008) A survey on pickup and delivery problems Part II: transportation between pickup and delivery locations. J Betriebswirtsch 58(2):81–117

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Choe, R., Kim, T.S., Kim, T. et al. Crane scheduling for opportunistic remarshaling of containers in an automated stacking yard. Flex Serv Manuf J 27, 331–349 (2015). https://doi.org/10.1007/s10696-013-9186-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10696-013-9186-3