Abstract

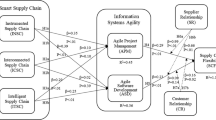

Agility can be viewed as a need to encourage the enterprise-wide integration of flexible and core competent resources so as to offer value-added product and services in a volatile competitive environment. Since flexibility is considered a property that provides change capabilities of different enterprise-wide resources and processes in time and cost dimensions, supply chain flexibility can be considered a composite state to enterprise-wide resources to meet agility needs. Enterprise modeling frameworks depicting these composite flexibility states are difficult to model because of the complex and tacit interrelationship among system parameters and also because agility thrives on many business objectives. In view of this, the modeling framework presented in this paper is based on analytical network process (ANP) since this methodology can accommodate the complex and tacit interrelationship among factors affecting enterprise agility. The modeling framework forms a three-level network with the goal of attaining agility from the perspective of market, product, and customer as the actors. The goal depends on substrategies that address the characteristics of the three actors. Each of these substrategies further depends on manufacturing, logistic, sourcing, and information technology (IT) flexibility elements of the enterprise supply chain (SC). The research highlights that, under different environmental conditions, enterprises require synergy among appropriate supply chain flexibilities for practising agility. In the present research, the ANP modeling software tool Super Decisions™ has been used for relative prioritization of the supply chain flexibilities. We demonstrate through sensitivity analysis that dynamic conditions do require adjustments in the enterprise-wide flexibility spectrum.

Similar content being viewed by others

References

Adams W (2004) Abstract, available as http://www.creativedecisions.net/papers/papers_etc/calcwhite-paper.pdf, cited in June, 2004

Anderson LD, Britt EF, Favre JD (1997) The seven principles of supply chain management. Supply Chain Manage Rev 1(Spring):31–43

Beach R, Muhlemann AP, Price DHR, Paterson A, Sharp JA (2000) A review of manufacturing flexibility. Eur J Oper Res 122:41–57

Browne J, Dubois D, Rathmill K, Sethi SP, Stecke KE (1984) Classification of flexible manufacturing systems. FMS Mag 2:114–117

Chan FTS, Chung SH, Wadhwa S (2004) A heuristic methodology for order distribution in a demand driven collaborative supply chain. Int J Prod Res 42(1):1–19

Da Silveira G, Borenstein D, Fogliatto FS (2001) Mass customization: literature review and research directions. Int J Prod Res 72:1–13

De Meyer A, Nakane J, Miller JG, Ferdows K (1989) Flexibility: the next competitive battle: the manufacturing futures survey. Strategic Manage J 10:135–144

Fawcett SE, Clinton SR (1996) Enhancing logistics performance to improve the competitiveness of manufacturing organizations. Prod Inventory Manage J 37:40–46

Ferdows K, De Meyar A (1990) Lasting improvements in manufacturing performance: in search of a new theory. J Oper Manage 9:168–183

Goldman SL, Nagel RN (1993) Management, technology and agility: the emergence of a new era in manufacturing. Int J Technol Manage 8:18–38

Goldman SL, Nagel RN, Preiss K (1995) Agile competitors and virtual organizations: strategies for enriching the customer. Von Nostrand Reinhold, New York, pp 3–60

Gunasakeran A (1998) Agile manufacturing: enablers and implementation framework. Int J Prod Res 36(5):1223–1247

Gunasakeran A (1999) Agile manufacturing: a framework for research and development. Int J Prod Econ 62:87–105

Harland D, Scharlaken WJ (1997) Global supply chain planning: synchronizing operations and logistics with the pulse of the international market place. In: 40th APICS international conference proceedings, pp 211–219

Jaikumar R (1986) Post-industrial manufacturing. Harvard Bus Rev 64(6):69–76

Kidd PT (1995) Agile manufacturing: forging new frontiers. Addison-Wesley, London

Leslie KD, Rhonda LR, Vokurka RJ (2001) A conceptual model of supply chain flexibility. In: Proceedings of decision sciences institute, pp 446–456

Meade LM, Liles DE, Sarkis J (1997) Justifying strategic alliances and partnering: a prerequisite for virtual enterprises. Omega Int J Manage Sci 25(1):29–42

Meade L, Sarkis J (1999) Analyzing organizational project alternatives for agile manufacturing processes: an analytical network approach. Int J Prod Res 37(2):241–261

Mishra MN, Wadhwa S (2003) A framework for agile manufacturing enterprises. In: Proceedings of INCARF, IIT Delhi, paper no. 371

Narasimhan R, Das A (1999) Manufacturing agility and supply chain practices. Prod Inventory Manage J, First Quart 40:4–10

Naylor JB, Naim MM, Berry D (1999) LeAgile: integrating the lean and agile manufacturing paradigms in the total supply chain. Int J Prod Econ 62:107–118

Nonaka I, Takeuchi H (1995) The knowledge-creating company: how Japanese companies create the dynamics of innovation. Oxford Univ. Press, New York

Olhager J, West BM (2002) The house of flexibility: using the QFD approach to deploy manufacturing flexibility. Int J Oper Prod Manage 22(1):50–79

Saaty TL (1980) The analytical hierarchy process. McGraw Hill, New York

Saaty TL (2001) Decision making with dependence and feedback: the analytic network process. RWS, Pittsburgh, pp 83–135

Sarkis J (2003) A strategic decision framework for green supply chain management. J Cleaner Prod 11:397–409

Scully J, Fawcett SE (1993) Comparative logistics and production cost for global manufacturing strategy. Int J Oper Prod Manage 13(12):62–78

Sharifi H, Colquhoun G, Barclay I, Dan Z (2001) Agile manufacturing: a management and operational framework. In: Proceedings of institution of mechanical engineers, part B, pp 857–869

Sharifi H, Zhang Z (1999) A methodology for achieving agility in manufacturing organizations: an introduction. Int J Prod Econ 62:7–22

Soliman F, Youssef M (2001) The impact of some recent developments in e-business on the management of next generation manufacturing. Int J Oper Prod Manage 21:538–564

Stecke KE (1992) Procedures to determine part mix ratios for independent demands in flexible manufacturing systems. IEEE Trans Eng Manage 39:359–369

Swafford P, Ghosh S, Murthy N (2003) A model of global supply chain agility and its impact on competitive performance. In: Proceedings of the 31st National DSI meeting, Florida, pp 103–103

Tan KC, Kanan VR, Handfield RB, Ghosh S (1998) Supply chain management: supplier performance and firm performance. Int J Purchasing Mater Manage 30:2–9

Tiwana A (2000) The knowledge management toolkit. Prentice Hall

Tomke SH (1997) The role of flexibility in the development of new products: an empirical study. Res Policy 26:105–119

Upton DM (1995) Flexibility as process mobility: the management of plant capabilities for quick response manufacturing. J Oper Manage 13(3):205–224

Upton DM (1997) Process range in manufacturing: an empirical study of flexibility. Manage Sci 43(8):1079–1092

Viswanadham N, Srinivasa R (1997) Flexibility in manufacturing enterprises. Sadhana India 22(2):135–163

Vokurka RJ, Fliedner G (1998) The journey toward agility. Ind Manage Data Syst 98(4):165–171

Wadhwa S, Browne J (1989) Modeling FMS with decision petri nets. Int J Flex Manuf Syst 1:253–280

Wadhwa S, Chopra A (2000) A genetic algorithm application: dynamic reconfiguration of agile manufacturing systems. J Stud Inform Control 9:1–9

Wadhwa S, Rao KS (2000) Flexibility: an emerging meta-competence for managing high technology. Int J Technol Manage 19(7):820–845

Wadhwa S, Rao KS (2002) Framework for a flexibility maturity model. Global J Flex Syst Manage 3(2):45–54

Wadhwa S, Rao KS (2003) Enterprise modeling of supply chains involving multiple entity flows: role of flexibility in enhancing lead time performance. SIC J 12(1):5–20

Wadhwa S, Rao KS (2004) A unified framework for manufacturing and supply chain flexibility. Global J Flex Syst Manage 51:15–22

Yang SL, Li TF (2002) Agility evaluation of mass customization product manufacturing. J Mater Process Technol 129:640–644

Yusuf YY, Sarhadi M, Gunasakeran A (1999) Agile manufacturing: the drivers, concepts and attributes. Int J Prod Econ 62:33–43

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wadhwa, S., Mishra, M. & Saxena, A. A network approach for modeling and design of agile supply chains using a flexibility construct. Int J Flex Manuf Syst 19, 410–442 (2007). https://doi.org/10.1007/s10696-008-9044-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10696-008-9044-x