Abstract

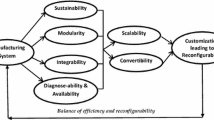

In a globally competitive market for products, manufacturers are faced with an increasing need to improve their flexibility, reliability, and responsiveness to meet the demands of their customers. Reconfigurable manufacturing systems (RMS) have become an important manufacturing paradigm, because they broadly encompass the ability to react efficiently to this environment by providing the exact capacity and functionality needed when needed. This paper studies how such new systems can manage their capacity scalability planning in a cost effective manner. An approach for modeling capacity scalability planning is proposed. The development of the model is based on set theory and the regeneration point theorem which is mapped to the reconfigurable manufacturing paradigm as the capacity scalability points of that system. The cost function of the model incorporates both the physical capacity cost based on capacity size and costs associated with the reconfiguration process which referred to as the scalability penalty cost and scalability effort cost. A dynamic programming (DP) approach is manipulated for the development of optimal capacity scalability plans. The effect of the reconfiguration costs on the capacity scalability planning horizon and overall cost is investigated. The results showed the relation between deciding on the optimal capacity scalability planning horizon and the different reconfiguration costs. Results also highlighted the fact that decreasing costs of reconfiguration will lead to cost effective implementation of reconfigurable manufacturing systems.

Similar content being viewed by others

References

Angelus A, Porteus EL, Wood SC (1997) Optimal sizing and timing of capacity expansion with implications for modular semiconductor wafer fabs, Graduate School of Business, Stanford University, Research Paper No. 1479R2

Asl R, Ulsoy A (2002a) Capacity management via feedback control in reconfigurable manufacturing systems, Proceeding of Japan-USA symposium on flexible manufacturing automation, Hiroshima, Japan

Asl R, Ulsoy A (2002b) Capacity management in reconfigurable manufacturing systems with stochastic market demand, Proceeding of ASME international mechanical engineering congress and exposition

Bertsekas D (1987) Dynamic programming: deterministic and stochastic models. Prentice Hall, Englewood Cliffs NJ

ElMaraghy H (2006) Flexible and Reconfigurable Manufacturing Systems Paradigms. Int J Flex Manuf Sys, Special Issue on Reconfigurable Manufacturing Systems 17(4):261–276

Freidenfelds J (1981) Capacity expansion alnalysis of simple models with applications. Elsevier North Holland Inc New York, New York

Koren Y, Heisel U, Jovane F, Moriwaki T (1999) Reconfigurable manufacturing system. Ann CIRP 48(2):527–540

Leachman RC, Carmon TF (1992) On capacity modeling for production planning with alternative machine types. IIE Trans 24(4):62–72

Liberpoulos G (2002) Production capacity modeling of alternative, non-identical flexible machines. Int J FMS, 14:345–359

Luss H (1982) Operation research and capacity expansion problems: a survey. Oper Res 30(5):907–947

Manne Alan S (1961) Capacity expansion and probabilistic growth. Econometrica 29(4):632–649

Manne Alan S (1967) Investments for capacity expansion, size, location, and time-phasin. The MIT Press, Cambridge MA

Rocklin A, Kashper M (1984) Capacity expansion/reduction of a facility with demand augmantation dynamics. Oper Res 32(2):133–147

Roundy R, Zhang F, Cakanyildirum M (2000) Optimal capacity expansion for multi-product, multi-machine manufacturing systems with stochastic demand, Technical Report 1271, School of Operations Research and Industrial Engineering. Cornell University, NY

Son SY, Olsen TL, Yip-Hoi D (2001) An approach to scalability and line balancing for reconfigurable manufacturing systems. Integr Manuf Syst 12(7):500–511

Son SY (2000) Design principles and methodologies for reconfigurable machining systems, Ph.D. Dissertation, University of Michigan

Spicer JP (2002) A design methodology for scalable machining systems, Ph.D. Dissertation, University of Michigan

Youssef AMA, ElMaraghy HA (2006) Assessment of manufacturing systems reconfiguration smoothness. Int J Adv Manuf Technol, paper reference # 3641 30(1-2):174–193.

Author information

Authors and Affiliations

Corresponding author

Additional information

An erratum to this article is available at http://dx.doi.org/10.1007/s10696-014-9207-x.

The Editor-in-Chief of the Flexible Services and Manufacturing Journal, formerly known as the International Journal of Flexible Manufacturing Systems, has decided to retract this article. Upon investigation carried out according to the Committee on Publication Ethics guidelines (COPE), it has been found that the article duplicates without proper attribution a significant portion of text from the same authors' publication, Ahmed M. Deif and Waguih ElMaraghy: Investigating optimal capacity scalability scheduling in a reconfigurable manufacturing system. International Journal of Ad-vanced Manufacturing Technology, (2007) 32: 557-562, DOI 10.1007/s00170-005-0354-9 (Published online: 22 February 2006)."

About this article

Cite this article

Deif, A.M., ElMaraghy, W. RETRACTED ARTICLE: Effect of reconfiguration costs on planning for capacity scalability in reconfigurable manufacturing systems. Int J Flex Manuf Syst 18, 225–238 (2006). https://doi.org/10.1007/s10696-006-9006-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10696-006-9006-0