Abstract

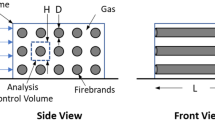

Characterizing propagation of a thermal runaway hazard in cell arrays and modules is critical to understanding fire hazards in energy storage systems. In this paper, the thermal runaway propagation of a pouch cell array has been examined by developing a 1D finite difference model. The results are compared with experimental data. First, the thermal runaway reactions found in the literature are reviewed. Using the insight of the literature review and premixed flame propagation theory, a global first order Arrhenius type reaction is characterized. While applying the multiple kinetic reactions, an “onset temperature” of the combustion reactions has been determined by performing an induction time analysis on ethylene. The propagation speeds are predicted with a 1D finite difference model by using both multi-reaction kinetics and one step reduced-order kinetics. These results are in a good agreement with experiments for both 10 Ah and 5 Ah cell arrays.

Similar content being viewed by others

References

Lopez CF, Jeevarajan JA, Mukherjee PP (2015) Experimental analysis of thermal runaway and propagation in lithium-ion battery modules. J Electrochem Soc 162(9):A1905–A1915. https://doi.org/10.1149/2.0921509jes

Feng X et al (2015) Characterization of penetration induced thermal runaway propagation process within a large format lithium ion battery module. J Power Sources 275:261–273. https://doi.org/10.1016/j.jpowsour.2014.11.017

Feng X, Lu L, Ouyang M, Li J, He X (2016) A 3D thermal runaway propagation model for a large format lithium ion battery module. Energy 115:194–208. https://doi.org/10.1016/j.energy.2016.08.094

Qi C, Zhu Y, Gao F, Yang K, Jiao Q (2018) Mathematical model for thermal behavior of lithium ion battery pack under overcharge. Int J Heat Mass Transf 124:552–563. https://doi.org/10.1016/j.ijheatmasstransfer.2018.03.100.

Gao S et al (2019) Experimental study on module-to-module thermal runaway-propagation in a battery pack. J Electrochem Soc 166(10):A2065–A2073. https://doi.org/10.1149/2.1011910jes

Said AO, Lee C, Stoliarov SI, Marshall AW (2019) Comprehensive analysis of dynamics and hazards associated with cascading failure in 18650 lithium ion cell arrays. Appl. Energy 248:415–428. https://doi.org/10.1016/j.apenergy.2019.04.141

Wang Q, Ping P, Zhao X, Chu G, Sun J, Chen C (2012) Thermal runaway caused fire and explosion of lithium ion battery. J Power Sources 208:210–224. https://doi.org/10.1016/j.jpowsour.2012.02.038

Feng X, Ouyang M, Liu X, Lu L, Xia Y, He X (2018) Thermal runaway mechanism of lithium ion battery for electric vehicles: a review. Energy Storage Mater 10:246–267. https://doi.org/10.1016/j.ensm.2017.05.013

Richard MN, Dahn JR (1999) Accelerating rate calorimetry study on the thermal stability of lithium intercalated graphite in electrolyte. I. Experimental. J Electrochem Soc 146(6):2068–2077. https://doi.org/10.1149/1.1391893

Richard MN, Dahn JR (1999) Accelerating rate calorimetry study on the thermal stability of lithium intercalated graphite in electrolyte. II. Modeling the results and predicting differential scanning calorimeter curves. J Electrochem Soc 146(6):2078–2084. https://doi.org/10.1149/1.1391894

Wang Q, Sun J, Yao X, Chen C (2006) Thermal behavior of lithiated graphite with electrolyte in lithium-ion batteries. J Electrochem Soc 153(2):A329–A333. https://doi.org/10.1149/1.2139955

Maleki H, Deng G, Kerzhner-Haller I, Anani A, Howard JN (2000) Thermal stability studies of binder materials in anodes for lithium-ion batteries. J Electrochem Soc 147(12):4470–4475. https://doi.org/10.1149/1.1394088

Feng X et al (2015) Thermal runaway propagation model for designing a safer battery pack with 25 Ah LiNi Co MnO2 large format lithium ion battery. Appl Energy 154:74–91. https://doi.org/10.1016/j.apenergy.2015.04.118

Hatchard TD, MacNeil DD, Basu A, Dahn JR (2001) Thermal model of cylindrical and prismatic lithium-ion cells. J Electrochem Soc 148(7):A755–A761. https://doi.org/10.1149/1.1377592

Kriston A, Adanouj I, Ruiz V, Pfrang A (2019) Quantification and simulation of thermal decomposition reactions of Li-ion battery materials by simultaneous thermal analysis coupled with gas analysis. J Power Sources 435:226774. https://doi.org/10.1016/j.jpowsour.2019.226774

Ren D et al (2018) Model-based thermal runaway prediction of lithium-ion batteries from kinetics analysis of cell components. Appl Energy 228:633–644. https://doi.org/10.1016/j.apenergy.2018.06.126

MacNeil DD, Dahn JR (2001) The reaction of charged cathodes with nonaqueous solvents and electrolytes: I. LixCoO2. J Electrochem Soc 148(11):A1205. https://doi.org/10.1149/1.1407245

MacNeil DD, Dahn JR (2001) The reaction of charged cathodes with nonaqueous solvents and electrolytes: II. LiMn2O4 charged to 4.2 V. J Electrochem Soc 148(11):A1211. https://doi.org/10.1149/1.1407246

MacNeil DD, Dahn JR (2001) Test of reaction kinetics using both differential scanning and accelerating rate calorimetries as applied to the reaction of LixCoO2 in non-aqueous electrolyte. J Phys Chem A 105(18):4430–4439. https://doi.org/10.1021/jp001187j

MacNeil DD, Dahn JR (2002) The reactions of Li0.5CoO2 with nonaqueous solvents at elevated temperatures. J Electrochem Soc 149(7):A912. https://doi.org/10.1149/1.1483865

Wang Q, Sun J, Yao X, Chen C (2005) Thermal stability of LiPF6/EC + DEC electrolyte with charged electrodes for lithium ion batteries. Thermochim Acta 437(1–2):12–16. https://doi.org/10.1016/j.tca.2005.06.010

Baba Y, Okada S, Yamaki J (2002) Thermal stability of LixCoO2 cathode for lithium ion battery. Solid State Ion 148(3–4):311–316. https://doi.org/10.1016/s0167-2738(02)00067-x

Wang L, Maxisch T, Ceder G (2007) A first-principles approach to studying the thermal stability of oxide cathode materials. Chem Mater 19(3):543–552. https://doi.org/10.1021/cm0620943

Jiang J, Dahn JR (2004) ARC studies of the thermal stability of three different cathode materials: LiCoO2; Li[Ni0.1Co0.8Mn0.1]O2; and LiFePO4, in LiPF6 and LiBoB EC/DEC electrolytes. Electrochem Commun 6(1):39–43. https://doi.org/10.1016/j.elecom.2003.10.011

Yamaki J, Shinjo Y, Doi T, Okada S (2014) The rate equation for oxygen evolution by decomposition of LixCoO2 at elevated temperatures. J Electrochem Soc 161(10):A1648–A1654. https://doi.org/10.1149/2.0621410jes

Furushima Y, Yanagisawa C, Nakagawa T, Aoki Y, Muraki N (2011) Thermal stability and kinetics of delithiated LiCoO2. J Power Sources 196(4):2260–2263. https://doi.org/10.1016/j.jpowsour.2010.09.076

Jung D-H, Umirov N, Kim T, Bakenov Z, Kim J-S, Kim S-S (2019) Thermal and structural stabilities of LixCoO2 cathode for Li secondary battery studied by a temperature programmed reduction. Eurasian Chem-Technol J 1:3. https://doi.org/10.18321/ectj780

Ping P, Wang Q, Huang P, Sun J, Chen C (2014) Thermal behaviour analysis of lithium-ion battery at elevated temperature using deconvolution method. Appl Energy 129:261–273. https://doi.org/10.1016/j.apenergy.2014.04.092

Wang QS, Sun JH, Chen CH, Zhou XM (2008) Thermal properties and kinetics study of charged LiCoO2 by TG and C80 methods. J Therm Anal Calorim 92(2):563–566. https://doi.org/10.1007/s10973-007-8289-z

Law CK (2010) Combustion physics. Cambridge University Press, Cambridge

Bilyaz S, Archibald E, Marr KC, Ezekoye OA (2019) Parameter estimation for battery kinetic and thermophysical parameters. In: ASTFE Digital Library

Somandepalli V, Marr K, Horn Q (2014) Quantification of combustion hazards of thermal runaway failures in lithium-ion batteries. SAE Int J Altern Powertrains 3:98–104. https://doi.org/10.4271/2014-01-1857

Varatharajan B, Williams FA (2002) Ethylene ignition and detonation chemistry, part 2: ignition histories and reduced mechanisms. J Propuls Power 18(2):352–362. https://doi.org/10.2514/2.5941

Merchant SS, Goldsmith CF, Vandeputte AG, Burke MP, Klippenstein SJ, Green WH (2015) Understanding low-temperature first-stage ignition delay: propane. Combust Flame 162(10):3658–3673. https://doi.org/10.1016/j.combustflame.2015.07.005

Acknowledgements

This work is supported by the United State Department of Homeland Security under Grant Number EMW-2016-FP-00833. Erik Archibald and Robert Kennedy are acknowledged for contributing the experimental data.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: Ignition Time Discussion

Appendix: Ignition Time Discussion

There are various hydrocarbons that may present when oxygen is available in the cell. The main fuel source is the electrolyte. Since DMC and DEC have high vapor pressures at low temperatures (low boiling tempearture), a significant amount of them might be vented before the presence of oxygen. Therefore, we assumed that when oxygen appears at around 240°C, the available fuel is rich for EC and its related Lithium-Electrolyte reaction (labeled as A3 or AnE in the text) product, ethylene (C2H4). Varatharajan and Williams [33] examined the ignition and detonation characteristics of ethylene extensively. At low temperatures, the ignition consist of a chain-branching stage and a constant concentration stage. In the chain-branching stage, the ethylene and oxygen starts forming radicals such as HO2 and H2O2. In the study [33], it is shown that the time of this chain-branching stage can be determined by the concentration of the HO2 radical. Thus, a reduced order chemical model is applied for the chain-branching stage and the time evolution for HO2 concentration has been modeled. [33] The evolution of the radical HO2 is given as

Chain-branching stage will end when the concentration of HO2 will reach the following

\(k\) and \(\alpha\) are the reaction rates such as

q and s are also related with reaction rates such as

where the subscript numbers are associated with the number of reactions defined in Varatharajan and Williams [33]. This means, for any initial C2H4, O2 concentration and temperature, the ignition time can be estimated as follows: starting with zero HO2 concentration, Eq. 29 can be integrated, and the ignition happens when HO2 concentration reaches the value determined by Eq. 30. This is often called numerical estimation. Varatharajan and Williams [33] also developed an analytical formula to estimate the chain-branching time as

Therefore, the ignition time can either be evaluated by using the analytical formula in Eq. 36, or numerically. Further details can be found in Varatharajan and Williams [33].

Concisely, the ignition time can be written as a function of temperature and initial fuel and oxygen concentrations as

Fuel and oxygen concentrations are determined by using a mixture concentration and an equivalence ratio. Using the equation of state, the concentration of the mixture can be evaulated as

In Eq. 38, P is the total pressure of the gas mixture and R is the specific gas constant. The concentration of the mixture can be distributed to the fuel and oxygen based on the equivalence ratio (\(\phi\)) as follows

Since the experiment was performed in a nitrogen environment, the oxygen that caused combustion must be provided by LCO decomposition. Many researchers observed the oxygen after 240°C or associated exothermic reactions to oxidation of electrolyte after 200°C. At this temperature, there can be flammable hydrocarbons in the cell due to Anode–Electrolyte reaction or electrolyte evaporation. As long as there is oxygen and fuel in the cell, combustion might occur, providing a sufficient time for auto-ignition. At low temperatures, the ignition times can be high due to long chain branching stages. For stoichiometric ethylene–oxygen mixture at 1 bar, the ignition times are predicted using the aforementioned analytical and numerical models and compared with the values in the literature in Fig. 10. The data provided by Varatharajan are evaluated by using detailed chemical mechanisms. Please note that for temperatures lower than 1000 K, Varatharajan does not provide ignition time data. Therefore, as a sanity check, we presented the ignition times of propane and butane in this low temperature (500 K to 1000 K) range [34]. The results are in a reasonable agreement.

At the lower temperatures for which the oxygen–hydrocarbon mixture may present in the cell, (after 240°C), assuming that the oxygen starts to be present after 240°C, it is possible to estimate the onset temperature of thermal runaway by evaluating the ignition time after oxygen is generated. Ignition is assumed to happen when the ignition time is achieved

A representative temperature profile is compared with the ignition times that are evaluated by the numerical model in Fig. 11. At the left-hand side of the dashed dot and solid curve intersection, the cell temperature is low and corresponding required ignition time is so high that the necessary conditions for ignition could not be achieved. When temperature is increased and intersected with the ignition time prediction, a sufficient time has been passed after the presence of oxygen and fuel, which makes the ignition possible. For the ignition time prediction, the pressure is set to 1.2 bar, which is measured by the load cell in the experiment.

Rights and permissions

About this article

Cite this article

Bilyaz, S., Marr, K.C. & Ezekoye, O.A. Modeling of Thermal Runaway Propagation in a Pouch Cell Stack. Fire Technol 56, 2441–2466 (2020). https://doi.org/10.1007/s10694-020-00970-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10694-020-00970-6