Abstract

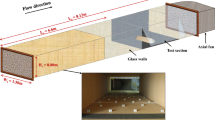

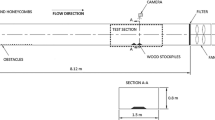

Emission factors are largely used to quantify particle emissions from industrial open storage piles. These factors are based on the knowledge of velocity distribution and flow patterns over the stockpile surface which still requires further research. The aim of the present work is to investigate the airflow characteristics over a single typical oblong pile and in its near-ground surroundings for various wind flow directions. Wind tunnel experiments using an oil-film surface coating technique were carried out for near-wall flow visualization. Numerical simulation results, favorably compared to PIV measurements, were used to allow comparison analysis of flow features. For the stockpile oriented 90° to the wind main direction, typical topology of flow around wall-mounted obstacles were observed, notably a wake zone downstream the pile including two main counter-rotating vortices. Further analysis of numerical wall shear stress distribution and streamlines indicates that two complex three-dimensional vortical flow structures develop downstream the pile. For other incoming wind flow directions (30 and 60°), the flow characteristics over the storage pile greatly differ as a single helical main vortex develops from the pile’s crest. Corresponding high values of wall shear stress are noticed downstream the storage pile. For each configuration studied, downwash and upwash zones are induced by the vortical structures developed. This near-wall flow topology combined with areas of high friction levels may be linked to potential dust emission from the ground surface surrounding industrial stockpiles.

Similar content being viewed by others

References

AbuOmar MM, Martinuzzi RJ (2008) Vortical structures around a surface-mounted pyramid in a thin boundary layer. J Wind Eng Ind Aerodyn 96: 769–778

Badr T, Harion J-L (2005) Numerical modellingof flow over stockpiles: implications on dust emissions. Atmos Environ 39: 5576–5584

Badr T, Harion J-L (2007) Effect of aggregate storage piles configuration on dust emissions. Atmos Environ 41: 360–368

Chen T, Liou L (2011) Blockage corrections in wind tunnel tests of small horizontal-axis wind turbines. Exp Therm Fluid Sci 35: 565–569

Desreumaux O, Bourez JP (1989) Préparation de bouillies pour visualisation pariétales sur maquette de sous-marin à à CEPRA 19. Rapport de l’Institut de Mécanique des Fluides de Lille (IMFL), numéro 89/19

Diego I, Pelegry A, Torno S, Toraño J, Menendez M (2009) Simultaneous CFD evaluation of wind flow and dust emission in open storage piles. Appl Math Model 33: 3197–3207

Ferreira AD, Lambert RJ (2011) Numerical and wind tunnel modeling on the windbreak effectiveness to control the aeolian erosion of conical stockpiles. Environ Fluid Mech 11: 61–76

Ferreira A, Fino M (2012) A wind tunnel study of wind erosion and profile reshaping of transverse sand piles in tandem. Geomorphology 139(140): 230–241

FLUENT User’s guide V6.3. http://www.ansys.com/Products/Simulation+Technology/Fluid+Dynamics/ANSYS+Fluent

Gowardhan A, Pardyjak E, Senocak I, Brown M (2011) A CFD-based wind solver for an urban fast response transport and dispersion model. Environmental Fluid Mechanics. doi:10.1007/s10652-011-9211-6

Guiming T (1994) Surface oil flow technique and liquid crystal thermography for flow visualization in impulse wind tunnels. Acta Mech Sin 10: 220–226

Havel B, Hangan H, Martinuzzi R (2001) Buffeting for 2D and 3D sharp-edged bluff bodies. J Wind Eng Ind Aerodyn 89: 1369–1381

Lee H-W, Park JJ, Lee JS (2002) Flow visualization and film cooling effectiviness measurements around shaped holes with compound angle orientations. J Heat Mass Transf 45: 145–156

Leeuw WC, Pagendarm H-G, Post FH, Walter B (1995) Visual simulation of experimental oil-flow visualization by spot noise images from numerical flow simulation. In: Sixth Eurographics workshop on visualization in scientific computing, vol 50. Springer, Wien, pp 150–165

Mosharov VY, Radchenko N (2009) Method of gas or liquid flow visualization on an object surface. http://www.patentstorm.us/applications/20090038407/fulltext.html

Pagendarm HG, Post H (1995) Comparative visualization—approaches and examples. Vis Sci Comput 15: 95–108

Sada K, Sato A (2002) Numerical calculation of flow and stack-gas concentration fluctuation around a cubical building. Atmos Environ 36: 5527–5534

Santos JM, Reis NC, Goulart EV, Mavroidis I (2009) Numerical simulation of flow and dispersion around an isolated cubical building: the effect of the atmospheric stratification. Atmos Environ 43: 5484–5492

Shi RF, Cui GX, Wang ZS, Xu CX, Zhang ZS (2008) Large eddy simulation of wind field and plume dispersion in building array. Atmos Environ 42: 1083–1097

Takeda K, Kato M (1992) Wind tunnel blockage effects on drag coefficient and wind-induced vibration. J Wind Eng Ind Aerodyn 42: 897–908

Toraño J, Torno S, Diego I, Menendez M, Gent M (2009) Dust emissions calculations in open storage piles protected by means of barriers, CFD and experimental tests. Environ Fluid Mech 9: 493–507

Turpin C (2010) Amélioration des modèles de quantification des émissions particulaires diffuses lieés a l’érosion éolienne de tas de stockage de matières granulaires sur sites industriels. PhD Thesis, University of Valenciennes, Industrial Energy Department, Ecole de Mines de Douai, France

Turpin C, Harion J-L (2009) Numerical modelling of flow structures over various flat-topped stockpiles height: implications on dust emissions. Atmos Environ 43: 5579–5587

Turpin C, Harion J-L (2010) Effect of the topography of an industrial site on dust emissions from open storage yards. Environ Fluid Mech 10: 677–690

US EPA (1985) Windbreak effectiveness for storage-pile fugitive-dust control. A wind Tunnel Study. Department of Marine, Earth and Atmospheric Sciences, North Carolina State University, EPA, NC 27695-8208

US EPA (2006) Miscellaneous sources, industrial wind erosion, AP-42, 5th edn, vol I, Chap 13.2.5, November 2006. http://www.epa.gov/ttn/chief/ap42/ch13/final/c13/final/c13s0205.pdf

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Furieri, B., Russeil, S., Harion, JL. et al. Experimental surface flow visualization and numerical investigation of flow structure around an oblong stockpile. Environ Fluid Mech 12, 533–553 (2012). https://doi.org/10.1007/s10652-012-9249-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10652-012-9249-0