Abstract

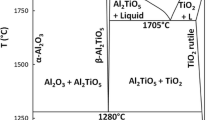

Processes of nonisothermal oxidation, nitridation, and ageing of aluminum powders with different particle sizes (nano-sized powder, ASD-1 powder, and PAP-2 powder) are considered. Application of non-oxide coatings onto particles of aluminum nanopowders reduces their thermal stability. Owing to scale-shaped particles, the PAP-2 powder after long-time storage preserves high activity of oxidation and nitridation, which is commensurable with that of the aluminum nanopowder. The activity of the coarse ASD-1 powder consisting of spherical particles in terms of oxidation and nitridation is low and only slightly changes during ageing.

Similar content being viewed by others

References

A. P. Il’in, A. A. Gromov, and G. V. Yablunovskii, “Reactivity of aluminum powders,” Combust., Expl., Shock Waves, 37, No. 4, 418–422 (2001).

N. Eisenreich, H. Fietzek, M. M. Juez-Lorenzo, et al., “On the mechanism of low temperature oxidation for aluminum particles down to the nano-scale,” Propell., Expl., Pyrotech., 29, No. 3, 137–145 (2004).

D. E. G. Jones, R. Turcotte, R. C. Fouchard, et al., “Hazard characterization of aluminum nanopowder compositions,” Propell., Expl., Pyrotech., 28, No. 3, 120–131 (2003).

A. Maranda, A. Papilski, and D. Galezowski, “Investigation on detonation and thermochemical parameters of aluminized ANFO,” Energ. Mater., 21, 1–13 (2003).

Yu. F. Ivanov, M. N. Osmonoliev, V. S. Sedoi, et al., “Productions of ultra-fine powders and their use in high energetic compositions,” Propell., Expl., Pyrotech., 28, No. 6, 319–333 (2003).

A. P. Il’in and A. A. Gromov, Combustion of Aluminum and Boron in a Superthin State [in Russian], Izd. Tomsk. Univ., Tomsk (2002).

A. I. Rat’ko, V. E. Romanenkov, E. V. Bolotnikova, and Zh. V. Krupen’kova, “Hydrothermal synthesis of a porous cermet material Al2O3/Al. I. Laws of oxidation of powdered aluminum and formation of the structure of the porous composite Al(OH)3/Al,” Kinet. Katal., 45, No. 1, 154–161 (2004).

J. C. Sanchez-Lopez, A. Fernandez, C. F. Conde, et al., “The melting behavior of passivated nanocrystalline aluminum,” Nanostruct. Mater., 7, No. 8, 813–822 (1996).

A. N. Zhigach, O. I. Leipunskii, M. L. Kuskov, et al., “Synthesis of coatings on the surface of ultrafine aluminum particles,” Khim. Fiz., 21, No. 4, 72–78 (2002).

A. L. Ramaswamy and P. Kaste, “Combustion modifiers for energetic materials,” in: Energetic Materials: Reactions of Propellants, Explosives and Pyrotechnics, Proc. 34th Int. Annual Conf. of ICT (June 24–27, Karlsruhe, 2003), Karlsruhe (2003), pp. (21-1)–(21-15).

Y. S. Kwon, A. A. Gromov, A. P. Ilyin, and G. H. Rim, “Passivation process for superfine aluminum powders obtained by electrical explosion of wires,” Appl. Surface Sci., 211, 57–67 (2003).

Y. S. Kwon, Y. H. Jung, N. A. Yavorovsky, et al., “Ultrafine metal powders by wires electric explosion method,” Scripta Mater., 44, 2247–2251 (2001).

A. P. Il’in, Yu. A. Krasnyatov, and D. B. Tikhonov, “Method for obtaining powders,” Patent of the Russian Federation No. 2139776.

B. Leo and A. W. Searcy, “The gaseous species of the Al-Al2O3 system,” J. Amer. Chem. Soc., 73, 5308–5314 (1951).

Author information

Authors and Affiliations

Additional information

__________

Translated from Fizika Goreniya i Vzryva, Vol. 42, No. 2, pp. 61–69, March–April, 2006.

Rights and permissions

About this article

Cite this article

Gromov, A.A., Il’in, A.P., Foerter-Barth, U. et al. Effect of the passivating coating type, particle size, and storage time on oxidation and nitridation of aluminum powders. Combust Explos Shock Waves 42, 177–184 (2006). https://doi.org/10.1007/s10573-006-0036-4

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/s10573-006-0036-4