Abstract

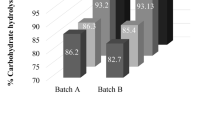

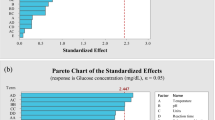

In an enzymatically driven lignocellulosic biorefinery, pretreatment and hydrolysis modules are the two most significant cost contributors for obtaining high gravity sugar solutions. The present study aimed to reduce the use of alkali and Cellic CTec2 during the bioprocessing of sugarcane bagasse (SCB). Later its impact on the overall process economics and the environment was evaluated. During pretreatment, solid loading of 15% (w/w) and use of 2% (w/v) sodium hydroxide at 121 °C for 30 min emerged as an optimum strategy. It resulted in > 65% delignification of SCB, retaining ≥ 90% and 65% of glucan and xylan fraction, respectively, in the pretreated biomass. Two approaches were evaluated in parallel to minimize the requirement of this commercial cellulase enzyme blend. The first strategy involved its partial replacement with an in-house enzyme cocktail by blending. The second route was performing hydrolysis with reduced loadings of cellulase enzyme blend above its optimum temperature, which gave more promising results. Hydrolysis of 20% alkali pretreated SCB with cellulase enzyme blend dosed at 15 mg protein g−1 glucan led to 84.13 ± 1 and 83.5 ± 2.3% glucan and xylan conversion yields respectively in 48 h at 52.5 °C. The filtrate and wash fraction contained ≥ 165 and ≥ 65 g L−1 sugar monomers representing glucose and xylose. However, in both the fractions > 75%, sugar accounted for glucose. The techno-economic analysis revealed that the sugar production cost from SCB was 1.32 US$/kg, with the optimized bioprocess. Environmental impact study showed that the process contributed to 1.57 kg CO2 eq in terms of climate change.

Similar content being viewed by others

Data availability

The raw data is available with us. On request, the same would be furnished.

References

Adsul M, Sandhu SK, Singhania RR et al (2020) Designing a cellulolytic enzyme cocktail for the efficient and economical conversion of lignocellulosic biomass to biofuels. Enzyme Microb. Technol 133:109442. https://doi.org/10.1016/j.enzmictec.2019.109442

Antunes FA, Chandel AK, Terán-Hilares R et al (2019) Overcoming challenges in lignocellulosic biomass pretreatment for second-generation (2G) sugar production: emerging role of nano, biotechnological and promising approaches. 3 Biotech 9(6):230. https://doi.org/10.1007/s13205-019-1761-1

Application Sheet of Novozymes (2010) Cellic® CTec2 and HTec2-enzymes for hydrolysis of lignocellulosic materials. https://www.yumpu.com/en/document/view/35286682/novozymes-cellicar-ctec2-and-htec2-enzymes-for-hydrolysis-of. Assessed on 15th Mar 2021

Ascencio JJ, Chandel AK, Philippini RR et al (2020) Comparative study of cellulosic sugars production from sugarcane bagasse after dilute nitric acid, dilute sodium hydroxide and sequential nitric acid-sodium hydroxide pretreatment. Biomass Convers Biorefin 10(4):813–822. https://doi.org/10.1007/s13399-019-00547-6

Baral P, Pundir A, Kumar V et al (2020a) Expeditious production of concentrated glucose-rich hydrolysate from sugarcane bagasse and its fermentation to lactic acid with high productivity. Food Bioprod Process 124:72–81. https://doi.org/10.1016/j.fbp.2020.08.005

Baral P, Jain L, Kurmi AK et al (2020b) Augmented hydrolysis of acid pretreated sugarcane bagasse by PEG 6000 addition: a case study of Cellic CTec2 with recycling and reuse. BioprocBiosysEngg 43(3):473–482. https://doi.org/10.1007/s00449-019-02241-3

Baruah J, Nath BK, Sharma R et al (2018) Recent trends in the pretreatment of lignocellulosic biomass for value-added products. Front Energy Res 6:141. https://doi.org/10.3389/fenrg.2018.00141

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. AnalBiochem 72(1–2):248–254. https://doi.org/10.1006/abio.1976.9999

Brar KK, Agrawal D, Chadha BS et al (2019) Evaluating novel fungal secretomes for efficient saccharification and fermentation of composite sugars derived from hydrolysate and molasses into ethanol. Bioresour Technol 273:114–121. https://doi.org/10.1016/j.biortech.2018.11.004

Brar KK, Santo MC, Pellegrini VO (2020) Enhanced hydrolysis of hydrothermally and autohydrolytically treated sugarcane bagasse and understanding the structural changes leading to improved saccharification. Biomass Bioenergy 139:105639. https://doi.org/10.1016/j.biombioe.2020.105639

Brondi MG, Elias AM, Furlan FF et al (2020) Performance targets defined by retro-techno-economic analysis for the use of soybean protein as saccharification additive in an integrated biorefinery. Sci Rep 10(1):1–13. https://doi.org/10.1038/s41598-020-64316-6

Chandel AK, Garlapati VK, Jeevan Kumar SP et al (2020) The role of renewable chemicals and biofuels in building a bioeconomy. Biofuel Bioprod Bioref. 14:830–844. https://doi.org/10.1002/bbb.2104

Cheng MH, Huang H, Dien BS et al (2019) The costs of sugar production from different feedstocks and processing technologies. Biofuel BioprodBioref 13(3):723–739. https://doi.org/10.1002/bbb.1976

Cheng MH, Kadhum HJ, Murthy GS et al (2020) High solids loading biorefinery for the production of cellulosic sugars from bioenergysorghum. BioresourTechnol 318:124051. https://doi.org/10.1016/j.biortech.2020.124051

da Silva AS, de Souza MF, Ballesteros I et al (2016) High-solids content enzymatic hydrolysis of hydrothermally pretreated sugarcane bagasse using a laboratory-made enzyme blend and commercial preparations. ProcBiochem 51(10):1561–1567. https://doi.org/10.1016/j.procbio.2016.07.018

Daful AG, Haigh K, Vaskan P et al (2016) Environmental impact assessment of lignocellulosic lactic acid production: integrated with existing sugar mills. Food Bioprod Process 99:58–70. https://doi.org/10.1016/j.fbp.2016.04.005

de Godoy CM, Machado DL, da Costa AC (2019) Batch and fed-batch enzymatic hydrolysis of pretreated sugarcane bagasse–assays and modeling. Fuel 253:392–399. https://doi.org/10.1016/j.fuel.2019.05.038

Dunaway KW, Dasari RK, Bennett NG (2010) Characterization of changes in viscosity and insoluble solids content during enzymatic saccharification of pretreated corn stover slurries. Bioresour Technol 101(10):3575–3582. https://doi.org/10.1016/j.biortech.2009.12.071

Fahmy M, Sohel MI, Vaidya AA et al (2019) Does sugar yield drive lignocellulosic sugar cost? Case study for enzymatic hydrolysis of softwood with added polyethylene glycol. ProcBiochem 80:103–111. https://doi.org/10.1016/j.procbio.2019.02.004

Galbe M, Wallberg O (2019) Pretreatment for biorefineries: a review of common methods for efficient utilization of lignocellulosic materials. Biotechnol Biofuels 12(1):1–26. https://doi.org/10.1186/s13068-019-1634-1

Ghosh TK (1987) Measurement of cellulase activities. Pure Appl Chem 59:257–268

Gong Z, Wang X, Yuan W et al (2020) Fed-batch enzymatic hydrolysis of alkaline organosolv-pretreated corn stover facilitating high concentrations and yields of fermentable sugars for microbial lipid production. Biotechnol Biofuels 13(1):13. https://doi.org/10.1186/s13068-019-1639-9

Harmsen PF, Huijgen W, Bermudez L et al (2010) Literature review of physical and chemical pretreatment processes for lignocellulosic biomass. Research Report ECN-E-10-013

Hodge DB, Karim MN, Schell DJ, McMillan JD (2008) Soluble and insoluble solids contributions to high-solids enzymatic hydrolysis of lignocellulose. Bioresourc Technol 99(18):8940–8948. https://doi.org/10.1016/j.biortech.2008.05.015

Humbird D, Davis R, Tao L et al (2011) Process design and economics for biochemical conversion of lignocellulosic biomass to ethanol: dilute-acid pretreatment and enzymatic hydrolysis of corn stover. Natl Renew Energy Lab. https://doi.org/10.2172/1107470

Jain L, Agrawal D (2018) Rational approach for mutant selection of Talaromycesverruculosus IIPC 324 secreting biofuel cellulases—assessing saccharification potential. Ind CropProd 114:93–97. https://doi.org/10.1016/j.indcrop.2018.01.078

Jain L, Kurmi AK, Agrawal D (2019) Benchmarking hydrolytic potential of cellulase cocktail obtained from mutant strain of Talaromycesverruculosus IIPC 324 with commercial biofuel enzymes. 3Biotech 9(1):23. https://doi.org/10.1007/s13205-018-1547-x

Kadhum HJ, Mahapatra DM, Murthy GS (2019) A comparative account of glucose yields and bioethanol production from separate and simultaneous saccharification and fermentation processes at high solids loading with variable PEG concentration. BioresourTechnol 283:67–75. https://doi.org/10.1016/j.biortech.2019.03.060

Kancelista A, Chmielewska J, Korzeniowski P et al (2020) Bioconversion of sweet sorghum residues by Trichodermacitrinoviride C1 enzymes cocktail for effective bioethanol production. Catalysts 10(11):1292. https://doi.org/10.3390/catal10111292

Kim DH, Park HM, Jung YH et al (2019) Pretreatment and enzymatic saccharification of oak at high solids loadings to obtain high titers and high yields of sugars. BioresourTechnol 284:391–397. https://doi.org/10.1016/j.biortech.2019.03.134

Kumar MN, Ravikumar R, Thenmozhi S et al (2019) Choice of pretreatment technology for sustainable production of bioethanol from lignocellulosic biomass: bottlenecks and recommendations. Waste Biomass Valor 10(6):1693–1709. https://doi.org/10.1007/s12649-017-0177-6

Kumar M, Pandey AK, Kumari S et al (2020) Secretome produced by a newly isolated Aspergillus flavus strain in engineered medium shows synergy for biomass saccharification with a commercial cellulase. Biomass Convers Bioref. https://doi.org/10.1007/s13399-020-00935-3

Li Y, Bhagwat SS, Cortés-Peña Y et al (2021) Sustainable lactic acid production from lignocellulosic biomass. ACS Sustain ChemEng 9:1341–1351. https://doi.org/10.1021/acssuschemeng.0c08055

Liu Y, Cao Y, Yu Q et al (2020) Enhanced sugars production with high conversion efficiency from alkali-pretreated sugarcane bagasse by enzymatic mixtures. BioResources 15(2):3839–3849

Maeda RN, Serpa VI, Rocha VA et al (2011) Enzymatic hydrolysis of pretreated sugar cane bagasse using Penicilliumfuniculosum and Trichodermaharzianumcellulases. ProcBiochem 46(5):1196–1201. https://doi.org/10.1016/j.procbio.2011.01.022

Manandhar A, Shah A (2020) Techno-economic analysis of bio-based lactic acid. Processes 8(2):199. https://doi.org/10.3390/pr8020199

Maryana R, Ma’rifatun D, Wheni AI et al (2014) Alkaline pretreatment on sugarcane bagasse for bioethanol production. EnergProcedia 47:250–254. https://doi.org/10.1016/j.egypro.2014.01.221

Morão A, de Bie F (2019) Life cycle impact assessment of polylactic acid (PLA) produced from sugarcane in Thailand. J Polymer Environ 27(11):2523–2539. https://doi.org/10.1007/s10924-019-01525-9

Mukasekuru MR, Kaneza P, Sun H et al (2020) Fed-batch high-solids enzymatic saccharification of lignocellulosic substrates with a combination of additives and accessory enzymes. Ind Crop Prod 146:112156. https://doi.org/10.1016/j.indcrop.2020.112156

Munagala M, Shastri Y, Konde K et al (2021) Valorization of sugarcane bagasse to lactic acid: life cycle assessment and economic evaluation in Indian scenario. Waste Manag 126:52–64. https://doi.org/10.1016/j.wasman.2021.02.052

Murali G, Shastri YS (2019) Biofuels Life cycle assessment based comparison of different lignocellulosic ethanol production routes. Biofuels. https://doi.org/10.1080/17597269.2019.1670465

Nalawade K, Baral P, Patil S et al (2020) Evaluation of alternative strategies for generating fermentable sugars from high-solids alkali pretreated sugarcane bagasse and successive valorization to L (+) lactic acid. Renew Energy 157:708–717. https://doi.org/10.1016/j.renene.2020.05.089

Ögmundarson Ó, Sukumara S, Herrgård MJ et al (2020) Combining environmental and economic performance for bioprocess optimization. Trends Biotechnol 38(11):1203–1214. https://doi.org/10.1016/j.tibtech.2020.04.011

Pachón ER, Vaskan P, Raman JK et al (2018) Transition of a South African sugar mill towards a biorefinery. A feasibility assessment. Applenerg 229:1–17. https://doi.org/10.1016/j.apenergy.2018.07.104

Rahmati S, Doherty W, Dubal D et al (2020) Pretreatment and fermentation of lignocellulosic biomass: reaction mechanisms and process engineering. ReactChemEng 5(11):2017–2047. https://doi.org/10.1039/D0RE00241K

Saini JK, Singhania RR, Satlewal A et al (2016) Improvement of wheat straw hydrolysis by cellulolytic blends of two Penicillium spp. Renew Energy 98:43–50. https://doi.org/10.1016/j.renene.2016.01.025

Saini R, Osorio-Gonzalez CS, Hegde K et al (2020) Lignocellulosic biomass-based biorefinery: an insight into commercialization and economic standout. Curr Sustain Renew Energy Rep 23:1–5. https://doi.org/10.1007/s40518-020-00157-1

Sharma S, Kuila A, Sharma V (2017) Enzymatic hydrolysis of thermochemically pretreated biomass using a mixture of cellulolytic enzymes produced from different fungal sources. Clean TechnolEnviron Policy 19(5):1577–1584. https://doi.org/10.1007/s10098-017-1346-9

Sluiter A, Hames B, Ruiz R et al (2010) Determination of structural carbohydrates and lignin in biomass. Laboratory Analytical Procedure (TP-510-42618)

Sreekumar A, Shastri Y, Wadekar P et al (2020) Life cycle assessment of ethanol production in a rice-straw-based biorefinery in India. Clean Technol Environ Policy 22:409–422. https://doi.org/10.1007/s10098-019-01791-0

Su CY, Yu CC, Chien IL et al (2013) Plant-wide economic comparison of lactic acid recovery processes by reactive distillation with different alcohols. IndEngChem Res 52:11070–11083. https://doi.org/10.1021/ie303192x

Valdivia M, Galan JL, Laffarga J et al (2016) Biofuels 2020: biorefineries based on lignocellulosic materials. MicrobBiotechnol 9(5):585–594. https://doi.org/10.1111/1751-7915.12387

Yang Y, Yang J, Liu J et al (2018) The composition of accessory enzymes of Penicilliumchrysogenum P33 revealed by secretome and synergistic effects with commercial cellulase on lignocellulose hydrolysis. BioresourTechnol 257:54–61. https://doi.org/10.1016/j.biortech.2018.02.028

Yoo CG, Meng X, Pu Y et al (2020) The critical role of lignin in lignocellulosic biomass conversion and recent pretreatment strategies: a comprehensive review. BioresourTechnol 301:122784. https://doi.org/10.1016/j.biortech.2020.122784

Zhao X, Zhang L, Liu D (2012a) Biomass recalcitrance. Part I: the chemical compositions and physical structures affecting the enzymatic hydrolysis of lignocellulose. Biofuels BioprodBioref 6(4):465–482. https://doi.org/10.1002/bbb.1331

Zhao X, Zhang L, Liu D (2012b) Biomass recalcitrance. Part II: fundamentals of different pretreatments to increase the enzymatic digestibility of lignocellulose. Biofuels BioprodBioref 6(5):561–579. https://doi.org/10.1002/bbb.1350

Zoghlami A, Paës G (2019) Lignocellulosic biomass: understanding recalcitrance and predicting hydrolysis. Front Chem 7:874. https://doi.org/10.3389/fchem.2019.00874

Acknowledgments

The authors are thankful to Dr Anjan Ray, Director CSIR-Indian Institute of Petroleum, for his valuable inputs and guidance. We are grateful to our industrial partner Dhampur Sugar Mills, Bijnor, India, for providing sugarcane bagasse.

Funding

The authors express their gratitude to the Department of Biotechnology (DBT), India, Biotechnology and Biological Sciences Research Council (BBSRC) and Innovate UK for funding the vWa Project (GAP 3513) under Indo-UK Industrial Waste 2017 grant.

Author information

Authors and Affiliations

Contributions

PB: Investigation, Methodology, Formal analysis, Writing-Original Draft; MM: Writing-Original Draft, Software, Formal analysis; YS: Supervision, Software, Resources, Data curation; VK: Writing- Review & Editing; DA- Conceptualization, Supervision, Writing-Original Draft, Project Management and Fund acquisition.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that that have no conflicts of interest.

Human and animal rights statement

No animal or human trials were undertaken or conducted by any of the authors during the said study.

Consent to participate

All the authors are aware of the submission and have given their consent to participate.

Consent to publish

All the authors have read the manuscript before submission. All authors read and approved the final manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Baral, P., Munagala, M., Shastri, Y. et al. Cost reduction approaches for fermentable sugar production from sugarcane bagasse and its impact on techno-economics and the environment. Cellulose 28, 6305–6322 (2021). https://doi.org/10.1007/s10570-021-03940-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-021-03940-5