Abstract

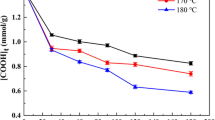

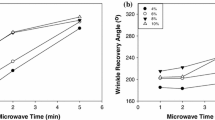

1,2,3,4-butanetetracarboxylic acid (BTCA) has been explored as formaldehyde-free crosslinking agent for many years. In this study, a novel kinetic model for cellulose reacted by BTCA was proposed and the factors that influenced the model parameters were investigated in detail, which could help us understand crosslinking mechanism clearly. Kinetic model, which is a consecutive reaction model, consisting of grafting (esterifying) reaction rate constant and crosslinking reaction rate constant, was deduced. The rate of the whole reaction depends on the rate of grafting reaction, which is related to the diffusion of free BTCA in pores of cellulose. However, the rate of crosslinking reaction depends on thermal vibration of cellulose chain grafted by BTCA, which is more sensitive to the change of curing temperature, especially when the temperature is higher than 150 °C. The Arrhenius activation energies of grafting and crosslinking reactions are 86.3 kJ/mol and 102.8 kJ/mol, respectively, showing high temperature is more conducive to increase the rate of crosslinking reactions comparing with grafting reaction. Moreover, the whole reaction is also affected by catalyst of SHP, which could react with BTCA anhydride to form BTCA-SHP compounds. Due to lower electron cloud density of carbonyl groups, BTCA-SHP compounds have much higher reactivity compared with BTCA anhydrides, which are beneficial to be attacked by hydroxyl groups in cellulose to form ester bonds, imparting excellent wrinkle-resistance to cotton fabrics.

Similar content being viewed by others

References

Brenda J, Choi H (1994) Thermal characteristics of unsaturated dicarboxylic acid durable press finishing systems. J Appl Polym Sci 51(5):769–779

Chen W, Lickfield GC, Yang CQ (2004) Molecular modeling of cellulose in amorphous state part II: effects of rigid and flexible crosslinks on cellulose. Polymer 45(21):7357–7365

Cui X, Honda T, Asoh TA, Uyama H (2019) Cellulose modified by citric acid reinforced polypropylene resin as fillers. Carbohyd Polym 230:115662

Dehabadi VA, Buschmann HJ, Gutmann JS (2013) Durable press finishing of cotton fabrics: an overview. Text Res J 83(18):1974–1995

Gu X, Yang CQ (2000) FTIR spectroscopy study of the formation of cyclic anhydride intermediates of polycarboxylic acids catalyzed by sodium hypophosphite. Text Res J 70(1):64–70

Harifi T, Montazer M (2012) Past, present and future prospects of cotton crosslinking: new insight into nano particles. Carbohyd Polym 88(4):1125–1140

Hosseinian A, Vessally E, Babazadeh M, Edjlali L, Es’ haghi M (2018) Adsorptionproperties of chloropicrin on pristine and borazine-doped nanographenes: a theoretical study. J Phys Chem Solids 115:277–282

Hou A, Sun G (2013) Multifunctional finishing of cotton fabrics with 3,3′,4,4′-benzophenone tetracarboxylic dianhydride: reaction mechanism. Carbohyd Polym 95(2):768–772

Ji B, Tang P, Yan K, Sun G (2015) Catalytic actions of alkaline salts in reactions between 1,2,3,4-butanetetracarboxylic acid and cellulose: II. Esterification Carbohyd Polym 132:228–236

Ji B, Qi H, Yan K, Sun G (2016) Catalytic actions of alkaline salts in reactions between 1,2,3,4-butanetetracarboxylic acid and cellulose: I. Anhydride Formation Cellulose 23:259–267

Ji B, Tang P, Hu C, Yan K (2019) Catalytic and ionic crosslinking actions of L-glutamate salt for the modification of cellulose by 1,2,3,4-butanetetracarboxylic acid. Carbohyd Polym 207:288–296

Kerfoot EJ, Mooney TF (1975) Formaldehyde and paraformaldehyde study in funeral homes. Am Ind Hyg Assoc J 36(7):533–537

Kristoffer L, Harald B (2013) Kinetics of cross-linking softwood kraft pulp with 1,2,3,4-Butanetetracarboxylic acid. Ind Eng Chem Res 52(33):11502–11509

Liu T, Peng X, Chen Y, Zhang J, Wang H (2020) Solid-phase esterification between poly(vinyl alcohol) and malonic acid and its function in toughening hydrogels. Polym Chem-Uk 11(29):4748–4749

Qi H, Zhao C, Qing F, Yan K, Sun G (2016) Antiwrinkle finishing of cotton fabrics with 5-(Carbonyloxy succinic)-benzene-1,2,4-tricarboxylic acid: comparison with other acids. Ind Eng Chem Res 55(46):11850–11856

Raimo N, Harri V (2010) Formaldehyde exposure in work and the general environment occurrence and possibilities for prevention. Scand J Work ENV HEA 7(2):95–100

Reinhardt RM, Harper RJ (1984) A comparison of aftertreatments to lower formaldehyde release from cottons crosslinked with various finishing agents. J Ind Text 13(4):216–227

Schramm C, Rinderer B, Bobleter O (1997) Kinetic data for the crosslinking reaction of polycarboxylic acids with cellulose. J Soc Dyers Colour 113(12):346–349

Steele R, Gidding LE (1956) Reaction of cellulose with dimethylol-and monomethylolureas. Ind Eng Chem Res 48(1):110–114

Trask-Morrell BJ, Choi HM (1994) Thermal characteristics of unsaturated dicarboxylic acid durable press finishing systems. J Appl Polym Sci 51(5):769–779

Yang CQ, Andrews BK (1991) Infrared spectroscopic studies of the nonformaldehyde durable press finishing of cotton fabrics by use of polycarboxylic acids. J Appl Polym Sci 43:1609–1616

Yang CQ (1993) Infrared spectroscopy studies of the cyclic anhydride as the intermediate for the ester crosslinking of cotton cellulose by polycarboxylic acids. I. Identification of the cyclic anhydride intermediate. J Polym Sci Pol Chem 31(5):1187–1193

Yang CQ, Bakshi GD (1996) Quantitative analysis of the nonformaldehyde durable press finish on cotton fabric: acid-base titration and infrared spectroscopy. Text Res J 66(6):377–384

Yang CQ, Wang DJ (2000) Evaluating ester crosslinking of cotton fabric by a polycarboxylic acid using acid-base titration. Text Res J 70(7):615–620

Yang CQ (2001) FTIR spectroscopy study of ester crosslinking of cotton cellulose catalyzed by sodium hypophosphite. Text Res J 71(3):201–206

Yang CQ (2003) Infrared spectroscopy studies of the cyclic anhydride as the intermediate for the ester crosslinking of cotton cellulose by polycarboxylic acids. I. Identification of the cyclic anhydride intermediate. J Polym Sci Pol Chem 31:1187–1193

Yang CQ (2013) Crosslinking: a route to improve cotton performance.". AATCC Rev 13(3):43–52

Zhao Q, Sun J, Liu B, He J (2015) Novel kinetics model for third-liquid phase-transfer catalysis system of the “complex” carbanion: competitive role between catalytic cycles. Chem Eng J 280:782–795

Acknowledgments

This research was supported by National Key Research and Development Program of China (2017YFB0309600) and the Fundamental Research Funds for Central Universities and Graduate Student Innovation Fund of Donghua University (No. CUSF-DH-D-2020064). And we also grateful for support offered by Jiangsu Lianfa Textile Co., Ltd., Nantong, China.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Hu, H., Xu, H., Dong, X. et al. Novel kinetics model for the crosslinking reaction of 1,2,3,4-butanetetracarboxylic acid with cellulose within cotton fabrics. Cellulose 28, 5071–5085 (2021). https://doi.org/10.1007/s10570-021-03823-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-021-03823-9