Abstract

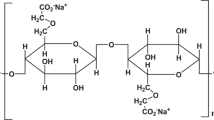

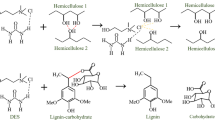

Cellulose carbamate is a bio-based, biodegradable, and environmentally friendly material and thus an interesting alternative to petroleum-based polymers or fibers from cellulose produced using the viscose process for producing fibers from cellulose. In this study we described an efficient and green method to prepare cellulose carbamates by using deep eutectic solvents. Three different urea-based deep eutectic solvents were used with different molar ratios and cellulose consistency. Nitrogen content of cellulose carbamates increases when cellulose consistency increases from 5 to 20%. Also, the reaction temperature affects the nitrogen content. In addition, the cellulose crystallinity decreases during the carbamation reaction with 20% cellulose consistency using any of the three deep eutectic solvents studied, when the sample is processed in a high-consistency reactor. By selecting suitable parameters, the nitrogen content of cellulose carbamates can be easily adjusted to a desired level.

Similar content being viewed by others

References

Abbott A, Capper G, Davies D, Rasheed R, Tambyrajah V (2003) Novel solvent properties of choline chloride/urea mixtures. Chem Commun 1:70–71

Abbott A, Boothby D, Capper G, Davies D, Rasheed R (2004) Deep eutectic solvents formed between choline chloride and carboxylic acids: versatile alternatives to ionic liquids. J Am Chem Soc 126:9142–9147

Abbott A, Capper G, Davies D, Rasheed R, Shikotra P (2005) Selective extraction of metals from mixed oxide matrixes using choline-based ionic liquids. Inorg Chem 44:6497–6499

Abbott A, Capper G, Davies D, McKenzie K, Obi S (2006) Solubility of metal oxides in deep eutectic solvents based on choline chloride. J Chem Eng Data 51(4):1280–1282

Abbott A, Cullis P, Gibson M, Harris R, Raven E (2007) Extraction of glycerol from biodiesel into a eutectic based ionic liquid. Green Chem 9:868–872

Edgar KJ, Buchanan CM, Debenham JS, Rundquist PA, Seiler BD, Shelton MC, Tindall D (2001) Advances in cellulose ester performance and application. Prog Polym Sci 26:1605–1688

Fernandes Diniz JMB, Gil MH, Castro JAAM (2004) Hornification—its origin and interpretation in wood pulps. Wood Sci Tecnol 37:489–494

Florindo C, Oliveira F, Rebelo L, Fernandes A, Marrucho I (2014) Insights into the synthesis and properties of deep eutetic solvents based on cholinium chloride and carboxylic acids. ACS Sustain Chem Eng 2:2416–2425

Fu F, Zhou J, Zhou X, Zhang L, Li D, Kondo T (2014) Green method for production of cellulose multifilament from cellulose carbamate on a pilot scale. ACS Sustain Chem Eng 2:2363–2370

Fu F, Xu M, Wang H, Wang Y, Ge H, Zhou J (2015) Improved synthesis of cellulose carbamates with minimum urea based on an easy scale-up method. ACS Sustain Chem Eng 3:1510–1517

Gorke J, Srienc F, Kazlauskas R (2008) Hydrolase-catalyzed biotransformations in deep eutectic solvents. Chem Commun 10:1235–1237

Guo Y, Zhou J, Song Y, Zhang L (2009) An efficient and environmentally friendly method for the synthesis of cellulose carbamate by microwave heating. Macromol Rapid Commun 30:1504–1508

Guo Y, Zhou J, Wang Y, Zhang L, Lin X (2010) An efficient transformation of cellulose into cellulose carbamates assisted by microwave irradiation. Cellulose 17:1115–1125

Hiltunen J, Kuutti L, Rovio S, Puhakka E, Virtanen T, Ohra-aho T, Vuoti S (2016) Using a low melting solvent mixture to extract value from wood biomass. Sci Rep 6:32420

Kato KL, Cameron RE (1999) A review of the relationship between thermally-accelerated ageing of paper and hornification. Cellulose 6:23–40

Klemm D, Heublein B, Fink HP, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem Int Ed 44:3358–3393

Lindman B, Karlström G, Stigsson L (2010) On the mechanisms of dissolution of cellulose. J Mol Liq 16:76–81

Lundström A, Andersson B, Olsson L (2009) Urea thermolysis studied under flow reactor conditions using DSC and FT-IR. Chem Eng J 150:544–550

Mormann W, Michel U (2002) Improved synthesis of cellulose carbamate without by-products. Carbohyd Polym 50:201–208

Nada A, Kamel S, El-Sakhawy M (2000) Thermal behavior and infrared spectroscopy of cellulose carbamates. Polym Degrad Stab 70:347–355

Newman RH (2004) Homogeneity in cellulose crystallinity between samples of Pinus radiate wood. Holzforschung 58:91–96

Park S, Baker J, Himmel M, Parilla P, Johnson D (2010) Cellulose crystallinity index: measurement techniques and their impact on interpreting cellulose performance. Biotechnol Biofuels 3:10

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Sharma M, Mukesh C, Mondal D, Prasad K (2013) Dissolution of α-chitin in deep eutectic solvents. RSC Adv 3:18149–18155

Smith E, Abbott A, Ryder K (2014) Deep eutectic solvents (DESs) and their applications. Chem Rev 114:11060–11082

Wahlström R, Hiltunen J, de Souza Pitaluga, Nascente Sirkka M, Vuoti S, Kruus K (2016) Comparison of three deep eutetic solvents and 1-ethyl-3-methylimidazolium acetate in the pretreatment of lignocellulose: effect on enzyme stability, lignocellulose digestibility and one-pot hydrolysis. RSC Adv 6:68100–68110

Weise U (1997) Characterization and mechanisms of changes in wood pulp fibres causes by water removal. Acta Polytechnic Scandinavica, 249, Finnish University of Technology

Yin C, Shen X (2007) Synthesis of cellulose carbamate by supercritical CO2-assisted impregnation: structure and rheological properties. Eur Polym J 43:2111–2116

Yin C, Li J, Xu Q, Peng Q, Liu Y, Shen X (2007) Chemical modification of cotton cellulose in supercritical carbon dioxide: synthesis and characterization of cellulose carbamate. Carbohyd Polym 67:147–154

Zeng C, Qi S, Xin R, Wang Y (2016) Synergistic behavior of betaine-urea mixture: formation of deep eutectic solvent. J Mol Liq 219:74–78

Zhang Q, Vigier K, Royer S, Jérôme F (2012) Deep eutectic solvents: syntheses, properties and applications. Chem Soc Rev 41:7108–7146

Zhang Y, Yin C, Zhang Y, Wu H (2013) Synthesis and Characterization of cellulose carbamate from wood pulp, assisted by supercritical carbon dioxide. Bioresources 8(1):1398–1408

Zhao H, Baker G, Holmes S (2011) New eutectic ionic liquids for lipase activation and enzymatic preparation of biodiesel. Org Biomol Chem 9(6):1908–1916

Acknowledgments

This work was a part of the ACel program of the Finnish Bioeconomy Cluster FIBIC. The funding of the Finnish Funding Agency for Technology and Innovation (TEKES) is acknowledged. We would like to thank Eija Silvasti, Mari Leino and Aleksi Sahari for their laboratory assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Willberg-Keyriläinen, P., Hiltunen, J. & Ropponen, J. Production of cellulose carbamate using urea-based deep eutectic solvents. Cellulose 25, 195–204 (2018). https://doi.org/10.1007/s10570-017-1465-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-017-1465-9