Abstract

Many tonnes of agricultural wastes are generated annually, which contains a relatively high amount of cellulose; banana pseudo-stem is one waste type that is a promising material for nanocellulose production. This research characterised nanocellulose from inner and outer layers of banana pseudo-stem as a preliminary research strategy for designing biodegradable packaging material from banana pseudo-stem nanocellulose. Nanocellulose was successfully prepared through TEMPO (2,2,6,6-tetramethylpiperidine 1-oxyl)-mediated oxidation. The extracted nanocellulose from both the inner and outer layers had observed widths of approximately 7–35 nm and long fibrillated fibre. They had high negative zeta potential (lower than −33.6) that provided good colloidal stability. The purity of the nanocellulose was high as demonstrated by 13C solid-state NMR and Fourier transform infrared spectroscopy. Nanocellulose from both layers was significantly more crystalline than the raw materials. Thermal stability of nanocellulose sourced from inner and outer layers was relatively similar, with degradation temperature of approximately 220 °C, which was slightly lower than the degradation temperature of its native form (232 °C for inner layer and 261 °C for outer layer).

Similar content being viewed by others

References

Abraham E, Deepa B, Pothan LA, Jacob M, Thomas S, Cvelbar U, Anandjiwala R (2011) Extraction of nanocellulose fibrils from lignocellulosic fibres: a novel approach. Carbohydr Polym 86:1468–1475. doi:10.1016/j.carbpol.2011.06.034

Arifuzzaman Khan G, Shams A, Kabir MR, Gafur M, Terano M, Alam M (2013) Influence of chemical treatment on the properties of banana stem fiber and banana stem fiber/coir hybrid fiber reinforced maleic anhydride grafted polypropylene/low-density polyethylene composites. J Appl Polym Sci 128:1020–1029

Aziz NAA, Ho LH, Azahari B, Bhat R, Cheng LH (2011) Chemical and functional properties of the native banana (Musa acuminata × balbisiana Colla cv. Awak) pseudo-stem and pseudo-stem tender core flours. Food Chem 128:748–753

Ball R, McIntosh AC, Brindley J (2004) Feedback processes in cellulose thermal decomposition: implications for fire-retarding strategies and treatments. Combust Theor Model 8:281–291. doi:10.1088/1364-7830/8/2/005

Bardet M, Foray MF, Trân Q-K (2002) High-resolution solid-state CPMAS NMR study of archaeological woods. Anal Chem 74:4386–4390

Carlsson DO, Lindh J, Strømme M, Mihranyan A (2015) Susceptibility of Iα-and Iβ-dominated cellulose to TEMPO-mediated oxidation. Biomacromolecules 16:1643–1649

Cordeiro N, Mendon C, Pothan LA, Varma A (2012) Monitoring surface properties evolution of thermochemically modified cellulose nanofibers from banana pseudo-stem. Carbohydr Polym 88:125–131

Dai L, Long Z, Lv Y, Zhang D, Deng HB, Liu Q (2015) TEMPO-mediated oxidation of cellulose in carbonate buffer solution. Fibers Polym 16:319–325

Deepa B et al (2011) Structure, morphology and thermal characteristics of banana nano fibers obtained by steam explosion. Bioresour Technol 102:1988–1997

Dufresne A (2013) Nanocellulose: a new ageless bionanomaterial. Mater Today 16:220–227

Fukuzumi H, Saito T, Iwata T, Kumamoto Y, Isogai A (2008) Transparent and high gas barrier films of cellulose nanofibers prepared by TEMPO-mediated oxidation. Biomacromolecules 10:162–165

Fukuzumi H, Saito T, Okita Y, Isogai A (2010) Thermal stabilization of TEMPO-oxidized cellulose. Polym Degrad Stab 95:1502–1508

Hatcher PG (1987) Chemical structural studies of natural lignin by dipolar dephasing solid-state 13C nuclear magnetic resonance. Org Geochem 11:31–39

Isogai A (2013) Wood nanocelluloses: fundamentals and applications as new bio-based nanomaterials. J Wood Sci 59:449–459

Isogai A, Saito T, Fukuzumi H (2011) TEMPO-oxidized cellulose nanofibers. Nanoscale 3:71–85

Jayaprabha JS, Brahmakumar M, Manilal VB (2011) Banana pseudostem characterization and its fiber property evaluation on physical and bioextraction. J Nat Fibers 8:149–160. doi:10.1080/15440478.2011.601614

Jiang F, Hsieh Y-L (2013) Chemically and mechanically isolated nanocellulose and their self-assembled structures. Carbohydr Polym 95:32–40

Li K, Fu S, Zhan H, Zhan Y, Lucia LA (2010) Analysis of the chemical composition and morphological structure of banana psudo-stem. BioResources 5:576–585

Li F, Mascheroni E, Piergiovanni L (2015) The potential of nanocellulose in the packaging field: a review. Packag Technol Sci 28:475–508

Lin J, Yu L, Tian F, Zhao N, Li X, Bian F, Wang J (2014) Cellulose nanofibrils aerogels generated from jute fibers. Carbohydr Polym 109:35–43. doi:10.1016/j.carbpol.2014.03.045

Lu C, Chen SY, Zheng Y, Zheng WL, Xiang C, Wang HP (2014) TEMPO-mediated oxidation of bacterial cellulose in buffer solution. In: Materials science forum. Trans Tech Publ, pp 90–94

Monspart-S´enyi J (2012) Fruit processing waste management. In: Sinha NK, Sidhu JS, Barta JSBW, Cano MP (eds) Handbook of fruits and fruit processing. Wiley, NewYork, pp 315–331

Mueller S, Weder C, Foster EJ (2014) Isolation of cellulose nanocrystals from pseudostems of banana plants RSC. Advances 4:907–915. doi:10.1039/C3RA46390G

Padam BS, Tin HS, Chye FY, Abdullah MI (2014) Banana by-products: an under-utilized renewable food biomass with great potential. J Food Sci Technol 51(12):3527–3545

Park S, Baker JO, Himmel ME, Parilla PA, Johnson DK (2010) Cellulose crystallinity index: measurement techniques and their impact on interpreting cellulase performance. Biotechnol Biofuels 3:1–10

Pelissari F, Sobral PA, Menegalli F (2014) Isolation and characterization of cellulose nanofibers from banana peels. Cellulose 21:417–432. doi:10.1007/s10570-013-0138-6

Pereira ALS, do Nascimento DM, Morais JPS, Vasconcelos NF, Feitosa JP, Brígida AIS, Rosa MDF (2014) Improvement of polyvinyl alcohol properties by adding nanocrystalline cellulose isolated from banana pseudostems. Carbohydr Polym 112:165–172

Phanthong P, Guan G, Ma Y, Hao X, Abudula A (2016) Effect of ball milling on the production of nanocellulose using mild acid hydrolysis method. J Taiwan Inst Chem Eng 60:617–622

Rusli R, Shanmuganathan K, Rowan SJ, Weder C, Eichhorn SJ (2011) Stress transfer in cellulose nanowhisker composites influence of whisker aspect ratio and surface charge. Biomacromolecules 12:1363–1369

Ryu S-R, Lee D-J (2001) Effects of fiber aspect ratio, fiber content, and bonding agent on tensile and tear properties of short-fiber reinforced rubber. KSME Int J 15:35–43

Saito T, Nishiyama Y, Putaux J-L, Vignon M, Isogai A (2006) Homogeneous suspensions of individualized microfibrils from TEMPO-catalyzed oxidation of native cellulose. Biomacromolecules 7:1687–1691

Saito T, Hirota M, Tamura N, Kimura S, Fukuzumi H, Heux L, Isogai A (2009) Individualization of nano-sized plant cellulose fibrils by direct surface carboxylation using TEMPO catalyst under neutral conditions. Biomacromolecules 10:1992–1996

Santhanam V, Chandrasekaran M, Venkateshwaran N (2013) Model I fracture toughness of banana fiber and glass fiber reinforced composites. Adv Mater Res 622–623:1320–1324

Sharma PR, Varma AJ (2014) Thermal stability of cellulose and their nanoparticles: effect of incremental increases in carboxyl and aldehyde groups. Carbohydr Polym 114:339–343

Shatkin JA, Wegner TH, Bilek ET, Cowie J (2014) Market projections of cellulose nanomaterial-enabled products-part 1: applications. TAPPI J 13(5):9–16

Silva L, Panzera T, Velloso V, Rubio J, Christoforo A, Scarpa F (2013) Statistical design of polymeric composites reinforced with banana fibres and silica microparticles. J Compos Mater 47:1199–1210

Tibolla H, Pelissari FM, Menegalli FC (2014) Cellulose nanofibers produced from banana peel by chemical and enzymatic treatment. LWT-Food Sci Technol 59:1311–1318

Tkacheva N, Morozov S, Grigor’ev I, Mognonov D, Kolchanov N (2013) Modification of cellulose as a promising direction in the design of new materials. Polym Sci Ser B 55:409–429

Velásquez-Cock J, Castro C, Gañán P, Osorio M, Putaux JL, Serpa A, Zuluaga R (2016) Influence of the maturation time on the physico-chemical properties of nanocellulose and associated constituents isolated from pseudostems of banana plant c.v valery. Ind Crops Prod 83:551–560. doi:10.1016/j.indcrop.2015.12.070

Vieira JG et al (2012) Synthesis and characterization of methylcellulose from cellulose extracted from mango seeds for use as a mortar additive. Polímeros 22:80–87

Vigneswaran C, Pavithra V, Gayathri V, Mythili K (2015) Banana fiber: scope and value added product development. J Text Appar Technol Manag 9(2):1–7

Walton D (1968) Natural polymers as film formers A. Cellulose for film manufacture. In: The science and technology of polymer films, Wiley, New York, pp 85–114

Wu C-N, Saito T, Fujisawa S, Fukuzumi H, Isogai A (2012) Ultrastrong and high gas-barrier nanocellulose/clay-layered composites. Biomacromolecules 13:1927–1932. doi:10.1021/bm300465d

Xu S, He Z, Tan W, Zhang Y (2013) Study on biological materials with the dehydration technology and equipment of banana stems. Appl Mech Mater 327:99–102

Acknowledgments

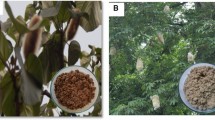

We acknowledge Dr. George Srzednicki for his kindness in assisting with the raw material supply, Mark Wainwright of the Analytical Centre for the electron microscope unit at the University of New South Wales, and the NMR facility of the Mark Wainwright Analytical Centre for access to the solid state NMR spectrometers.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Fig. S1

XRD spectra of the banana pseudo-stem nanocellulose from the outer layer (O2) and the acid-treated banana pseudo-stem cellulose (AT). AT was prepared by hydrolysing the bleached banana pseudo-stem from the outer layer with 1 % H2SO4 for 2 h at 60 °C. (TIFF 384 kb)

Rights and permissions

About this article

Cite this article

Faradilla, R.H.F., Lee, G., Rawal, A. et al. Nanocellulose characteristics from the inner and outer layer of banana pseudo-stem prepared by TEMPO-mediated oxidation. Cellulose 23, 3023–3037 (2016). https://doi.org/10.1007/s10570-016-1025-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-016-1025-8