Abstract

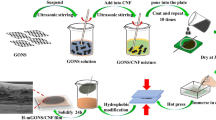

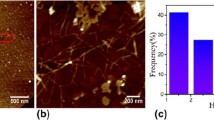

The ability to resist various solvents is critical during the preparation of flexible electronics on cellulose nanofiber (CNF) films via solution-phase coating process, as solvent cleaning steps are performed before and after the device fabrication, and solvent-based functional inks are used during the production process. However, literature on the solvent-resistance of CNF films is scarce. In this study, we investigated the solvent resistance of 2,2,6,6-tetramethylpiperidine-1-oxyl treated CNF films (TTCFs) in terms of solvent inertness and barrier properties against solvents by separately immersing the films in seven different organic solvents. As a result, the TTCFs exhibited excellent solvent resistance with no obvious change in their optical and mechanical properties, as well as dimensional and thermal stability after solvent treatment for 24 h. Furthermore, a novel method based on color-fading of thermal paper was first proposed to evaluate the barrier properties of the TTCF against diverse solvents. By applying a CNF film with a minimum coating weight of 3.94 g/m2, the thermal paper acquired the desirable barrier properties. The superior anti-solvent performance, along with the excellent stability, paves the way for the fabrication of next-generation green electronics on biodegradable and renewable TTCFs.

Similar content being viewed by others

References

Abdul Khalil HPS, Bhat AH, Ireana Yusra AF (2012) Green composites from sustainable cellulose nanofibrils: a review. Carbohydr Polym 87:963–979

Aulin C (2009) Novel oil resistant cellulosic materials. Doctoral Thesis in Pulp and Paper Industry, KTH Chemical Science and Engineering, Stockholm

Aulin C, Gällstedt M, Lindström T (2010) Oxygen and oil barrier properties of microfibrillated cellulose films and coatings. Cellulose 17:559–574

Bollström R, Määttänen A, Tobjörk D, Ihalainen P, Kaihovirta N, Österbacka R, Peltonen J, Toivakka M (2009) A multilayer coated fiber-based substrate suitable for printed functionality. Org Electron 10:1020–1023

Bollström R, Saarinen JJ, Räty J, Toivakka M (2012a) Measuring solvent barrier properties of paper. Meas Sci Technol 23:015601

Bollström R, Tuominen M, Määttänen A, Peltonen J, Toivakka M (2012b) Top layer coatability on barrier coatings. Prog Org Coat 73:26–32

Bollström R, Tobjörk D, Dolietis P, Salminen P, Preston J, Österbacka R, Toivakka M (2013) Printability of functional inks on multilayer curtain coated paper. Chem Eng Process 68:13–20

Bollström R, Pettersson F, Dolietis P, Preston J, Österbacka R, Toivakka M (2014) Impact of humidity on functionality of on-paper printed electronics. Nanotechnology 25:094003

Fang Z, Zhu H, Bao W, Preston C, Liu Z, Dai J, Li Y, Hu L (2014) Highly transparent paper with tunable haze for green electronics. Energy Environ Sci 7:3313–3319

Fujisaki Y, Koga H, Nakajima Y, Nakata M, Tsuji H, Yamamoto T, Kurita T, Nogi M, Shimidzu N (2014) Transparent nanopaper-based flexible organic thin-film transistor array. Adv Funct Mater 24:1657–1663

Fukuzumi H, Saito T, Iwata T, Kumamoto Y, Isogai A (2008) Transparent and high gas barrier films of cellulose nanofibers prepared by TEMPO-mediated oxidation. Biomacromolecules 10:162–165

Ha D, Fang Z, Hu L, Munday JN (2014) Paper-based anti-reflection coatings for photovoltaics. Adv Energy Mater 4:1301804

Hu L, Liu N, Eskilsson M, Zheng G, McDonough J, Wågberg L, Cui Y (2013a) Silicon-conductive nanopaper for Li-ion batteries. Nano Energy 2:138–145

Hu L, Zheng G, Yao J, Liu N, Weil B, Eskilsson M, Karabulut E, Ruan Z, Fan S, Bloking JT (2013b) Transparent and conductive paper from nanocellulose fibers. Energy Environ Sci 6:513–518

Huang J, Zhu H, Chen Y, Preston C, Rohrbach K, Cumings J, Hu L (2013) Highly transparent and flexible nanopaper transistors. ACS Nano 7:2106–2113

Isogai A, Saito T, Fukuzumi H (2011) TEMPO-oxidized cellulose nanofibers. Nanoscale 3:71–85

Jung YH, Chang T-H, Zhang H, Yao C, Zheng Q, Yang VW, Mi H, Kim M, Cho SJ, Park D-W (2015) High-performance green flexible electronics based on biodegradable cellulose nanofibril paper. Nat Commun 6:7170

Lagaron JM, Catalá R, Gavara R (2004) Structural characteristics defining high barrier properties in polymeric materials. Mater Sci Technol 20:1–7

Lavoine N, Desloges I, Dufresne A, Bras J (2012) Microfibrillated cellulose—its barrier properties and applications in cellulosic materials: a review. Carbohydr Polym 90:735–764

Lavoine N, Desloges I, Khelifi B, Bras J (2014) Impact of different coating processes of microfibrillated cellulose on the mechanical and barrier properties of paper. J Mater Sci 49:2879–2893

Määttänen A, Ihalainen P, Bollström R, Toivakka M, Peltonen J (2010) Wetting and print quality study of an inkjet-printed poly (3-hexylthiophene) on pigment coated papers. Colloids Surf A 367:76–84

McGonigle EA, Liggat JJ, Pethrick RA, Jenkins SD, Daly JH, Hayward D (2001) Permeability of N2, Ar, He, O2 and CO2 through biaxially oriented polyester films—dependence on free volume. Polymer 42:2413–2426

Miettunen K, Vapaavuori J, Tiihonen A, Poskela A, Lahtinen P, Halme J, Lund P (2014) Nanocellulose aerogel membranes for optimal electrolyte filling in dye solar cells. Nano Energy 8:95–102

Minelli M, Baschetti MG, Doghieri F, Ankerfors M, Lindström T, Siró I, Plackett D (2010) Investigation of mass transport properties of microfibrillated cellulose (MFC) films. J Membr Sci 358:67–75

Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40:3941–3994

Nakagaito AN, Nogi M, Yano H (2010) Displays from transparent film of natural nanofibers. MRS Bull 35:214–218

Nogi M, Komoda N, Otsuka K, Suganuma K (2013) Foldable nanopaper antennas for origami electronics. Nanoscale 5:4395–4399

Österberg M, Vartiainen J, Lucenius J, Hippi U, Seppälä J, Serimaa R, Laine J (2013) A fast method to produce strong NFC films as a platform for barrier and functional materials. ACS Appl Mater Interfaces 5:4640–4647

Preston C, Fang Z, Murray J, Zhu H, Dai J, Munday JN, Hu L (2014) Silver nanowire transparent conducting paper-based electrode with high optical haze. J Mater Chem C 2:1248–1254

Saito T, Isogai A (2005) A novel method to improve wet strength of paper. Tappi J 4:3–8

Saito T, Nishiyama Y, Putaux J-L, Vignon M, Isogai A (2006) Homogeneous suspensions of individualized microfibrils from TEMPO-catalyzed oxidation of native cellulose. Biomacromolecules 7:1687–1691

Saito T, Kimura S, Nishiyama Y, Isogai A (2007) Cellulose nanofibers prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolecules 8:2485–2491

Saito T, Hirota M, Tamura N, Kimura S, Fukuzumi H, Heux L, Isogai A (2009) Individualization of nano-sized plant cellulose fibrils by direct surface carboxylation using TEMPO catalyst under neutral conditions. Biomacromolecules 10:1992–1996

Siqueira G, Bras J, Dufresne A (2010) Cellulosic bionanocomposites: a review of preparation, properties and applications. Polymers 2:728–765

Syverud K, Stenius P (2009) Strength and barrier properties of MFC films. Cellulose 16:75–85

Xiao SY, Yang YQ, Li MX, Wang FX, Chang Z, Wu YP, Liu X (2014) A composite membrane based on a biocompatible cellulose as a host of gel polymer electrolyte for lithium ion batteries. J Power Sources 270:53–58

Yada H, Seki S (2013) Heat sensitive recording material comprising a protective layer. Google Patents US Patent 8,415,270

Zardetto V, Brown TM, Reale A, Di Carlo A (2011) Substrates for flexible electronics: a practical investigation on the electrical, film flexibility, optical, temperature, and solvent resistance properties. J Polym Sci Part B Polym Phys 49:638–648

Zhu H, Xiao Z, Liu D, Li Y, Weadock NJ, Fang Z, Huang J, Hu L (2013) Biodegradable transparent substrates for flexible organic-light-emitting diodes. Energy Environ Sci 6:2105–2111

Zhu H, Fang Z, Preston C, Li Y, Hu L (2014) Transparent paper: fabrications, properties, and device applications. Energy Environ Sci 7:269–287

Acknowledgments

Zhiqiang Fang would like to acknowledge the financial support from China Postdoctoral Science Foundation (2015M570716), the Fundamental Research Funds for the Central Universities (2015ZM156), and self-determined and innovative research funds of State Key Laboratory of Pulp and Papermaking Engineering (2015QN01). Siyi Min acknowledges the financial support from the Innovative Research Program for Undergraduate (081056122).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kuang, Y., Chen, G., Ming, S. et al. Solvent resistance of 2,2,6,6-tetramethylpiperidine-1-oxyl (TEMPO) treated cellulose nanofiber film for flexible electronics. Cellulose 23, 1979–1987 (2016). https://doi.org/10.1007/s10570-016-0906-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-016-0906-1