Abstract

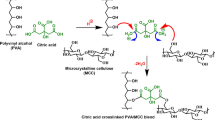

Several studies demonstrate that the addition of microfibrillated cellulose (MFC) to urea-formaldehyde (UF) wood adhesive improves the mechanical bond strength of wood particle board. In order to elucidate potential underlying mechanisms, the distribution of unmodified UF as well as MFC-modified UF (UF-MFC) in particle board was studied by means of light microscopy. The viscosity and cure characteristic of the adhesive systems were also characterised. UF-MFC showed high viscosity and shear thinning compared to UF. Both chemical and mechanical cure of adhesive were delayed in the presence of MFC. In UF-MFC, the size distribution of adhesive particles shifts towards larger particles compared to UF. More adhesive is directly available for adhesive bonding, and a larger part of the wood is covered with adhesive. This may be the cause for the better mechanical performance of particle board bonded with UF-MFC compared to UF.

Similar content being viewed by others

References

Charreau H, Foresti ML, Vázquez A (2013) Nanocellulose patents trends: a comprehensive review on patents on cellulose nanocrystals, microfibrillated and bacterial cellulose. Recent Pat Nanotechnol 7(1):56–80

Clauß S, Allenspach K, Gabriel J, Niemz P (2011) Improving the thermal stability of one-component polyurethane adhesives by adding filler material. Wood Sci Technol 45:383–388

Diem H, Matthias G, Wagner RA (2010) Amino resins. In: Ullmann’s encyclopaedia of industrial chemistry. doi:10.1002/14356007.a02_115.pub2

Dimić-Mišić K, Sanavane Y, Paltakari J, Maloney T (2013) Small scale rheological observation of high consistency nanofibrillar material based furnishes. J Appl Eng Sci 11(3):146

Dufresne A (2012) Nanocellulose: from nature to high performance tailored materials. Walter de Gruyter, Berlin

Dukarska D, Czarnecki R (2015) Fumed silica as a filler for MUPF resin in the process of manufacturing water-resistant plywood. Eur J Wood Wood Prod. doi:10.1007/s00107-015-0955-4

Dunky M, Niemz P (2002) Holzwerkstoffe und Leime - Technologie und Einflußfaktoren. Springer, Berlin

Eichhorn SJ, Dufresne A, Aranguren M, Marcovich NE, Capadona JR, Rowan SJ, Weder C, Thielemans W, Roman M, Renneckar S, Gindl W, Veigel S, Keckes J, Yano H, Abe K, Nogi M, Nakagaito AN, Mangalam A, Simonsen J, Benight AS, Bismarck A, Berglund LA, Peijs T (2010) Review: current international research into cellulose nanofibres and nanocomposites. J Mater Sci 45(1):1–33

EN 319 (1993) Particleboards and fiberboards-determination of tensile strength perpendicular to the plane of the board. Austrian Standards Institute, Vienna, Austria

EN 323 (1993) Wood-based panels-determination of density. Austrian Standards Institute, Vienna, Austria

Frihart CR (2009) Adhesive groups and how they relate to the durability of bonded wood. J Adhes Sci Technol 23(4):601–617

Gardner DJ, Oporto GS, Mills R, Azizi Samir MAS (2008) Adhesion and surface issues in cellulose and nanocellulose. J Adhes Sci Technol 22:545–567

Grüneberger F, Künninger T, Zimmermann T, Arnold M (2014) Rheology of nanofibrillated cellulose/acrylate systems for coating applications. Cellulose 21(3):1313–1326

Iotti M, Gregersen ØW, Moe S, Lenes M (2011) Rheological studies of microfibrillar cellulose water dispersions. J Polym Environ 19(1):137–145

Jorfi M, Foster EJ (2015) Recent advances in nanocellulose for biomedical applications. J Appl Polym Sci 132(14). doi:10.1002/app.41719

Kaboorani A, Riedl B, Blanchet P, Fellin M, Hosseinaei O, Wang S (2012) Nanocrystalline cellulose (NCC): a renewable nano-material for polyvinyl acetate (PVA) adhesive. Eur Polymer J 48(11):1829–1837

Klemm D, Kramer F, Moritz S, Lindström T, Ankerfors M, Gray D, Dorris A (2011) Nanocelluloses: a new family of nature-based materials. Angew Chem 50(24):5438–5466

Leemann U, Ruch F (1972) Cytofluorometric determination of basic and total proteins with sulfaflavine. J Histochem Cytochem 20(9):659–671

Lei H, Du G, Pizzi A, Celzard A (2008) Influence of nanoclay on urea-formaldehyde resins for wood adhesives and its model. J Appl Polym Sci 109(4):2442–2451

Lei H, Du G, Pizzi A, Celzard A, Fang Q (2010) Influence of nanoclay on phenol-formaldehyde and phenol-urea-formaldehyde resins for wood adhesives. J Adhes Sci Technol 24(8):1567–1576

Liu J, Howard GD, Lewis SH, Barros MD, Stansbury JW (2012) A study of shrinkage stress reduction and mechanical properties of nanogel-modified resin systems. Eur Polymer J 48(11):1819–1828

Mahrdt E, Stöckel F, van Herwijnen HWG, Müller U, Kantner W, Moser J, Gindl-Altmutter W (2015) Light microscopic detection of UF adhesive in industrial particle board. Wood Sci Technol. doi:10.1007/s00226-015-0715-y

Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40(7):3941–3994

Puisto A, Illa X, Mohtaschemi M, Alava M (2012) Modeling the rheology of nanocellulose suspensions. Nord Pulp Pap Res J 27(2):277–281

Richter K, Bordeanu N, López-Suevos F, Zimmermann T (2009) Performance of cellulose nanofibrils in wood adhesives. In: Proceedings of the Swiss bonding, pp 239–246

Riegler M, Gindl-Altmutter W, Hauptmann M, Müller U (2012) Detection of UF resin on wood particles and in particleboards: potential of selected methods for practice-oriented offline detection. Eur J Wood Wood Prod 70(6):829–837

Salari A, Tabarsa T, Khazaeian A, Saraeian A (2013) Improving some of applied properties of oriented strand board (OSB) made from underutilized low quality paulownia (Paulownia fortunie) wood employing nano-SiO2. Ind Crops Prod 42(1):1–9

Salas C, Nypelö T, Rodriguez-Abreu C, Carrillo C, Rojas OJ (2014) Nanocellulose properties and applications in colloids and interfaces. Curr Opin Colloid Interface Sci 19(5):383–396

Veigel S, Müller U, Keckes J, Obersriebnig M, Gindl-Altmutter W (2011) Cellulose nanofibrils as filler for adhesives: effect on specific fracture energy of solid wood-adhesive bonds. Cellulose 18(5):1227–1237

Veigel S, Rathke J, Weigl M, Gindl-Altmutter W (2012) Particle board and oriented strand board prepared with nanocellulose-reinforced adhesive. J Nanomater. doi:10.1155/2012/158503

Wang J, Laborie MPG, Wolcott MP (2011) Correlation of mechanical and chemical cure development for phenol-formaldehyde resin bonded wood joints. Thermochim Acta 513(1–2):20–25

Wei H, Rodriguez K, Renneckar S, Vikesland PJ (2014) Environmental science and engineering applications of nanocellulose-based nanocomposites. Environ Sci Nano 1(4):302–316

Zahedsheijani R, Faezipour M, Tarmian A, Layeghi M, Yousefi H (2012) The effect of Na+ montmorillonite (NaMMT) nanoclay on thermal properties of medium density fiberboard (MDF). Eur J Wood Wood Prod 70(5):565–571

Acknowledgments

The authors gratefully acknowledge the financial support by the Austrian Comet program (Competence Centre for Wood Composites and Wood Chemistry, Wood K Plus, Austria). They would also like to thank Metadynea (Metadynea Austria GmbH) for providing adhesives.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mahrdt, E., Pinkl, S., Schmidberger, C. et al. Effect of addition of microfibrillated cellulose to urea-formaldehyde on selected adhesive characteristics and distribution in particle board. Cellulose 23, 571–580 (2016). https://doi.org/10.1007/s10570-015-0818-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-015-0818-5