Abstract

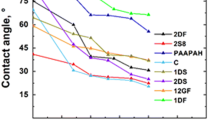

A chemically modified hydrophobic cellulose material was wetted by force in vacuo and allowed to dry under ambient conditions. Most known materials shrink upon drying and swell upon wetting, a phenomenon known as dry-shrinkage; and thus are characterized by a dry-shrinkage coefficient either equal or greater than zero. Different from conventional materials, sheets of hydrophobic cellulose fibres expand upon drying, which implies that they exhibit dry-expansion. This property is calculated as a negative dry-shrinkage coefficient. We are unaware of any other material with this property. Such sheets can expand to over 500 % in thickness upon drying in the first cycle of use. This property degrades with each cycle because more hydrophilic areas come in contact with water as a result of mechanical damage to the material, thus making the sheets less hydrophobic. With increasing solid content, a decrease in tensile strength is observed, which is opposite to the conventional trend in wet web strength. A mechanism for the dry-expansion of this material is being proposed.

Similar content being viewed by others

References

Hermans PH, Vermaas JJ, Vermaas D (1945) Density of cellulose fibers. II. Density and refractivity of model filaments. J Polym Sci 1(3):156–161

Jayme G (1944) Micromeasurements of the swelling of pulps. Papierfabrikant-Wochenblatt Fuer Papierfabrikation 6:187–194

Li S, Xie H, Zhang S, Wang X (2007) Facile transformation of hydrophilic cellulose into superhydrophobic cellulose. Chem Commun 46:4857–4859

Marklund E, Varna J (2009) Modeling the hygroexpansion of aligned wood fiber composites. Compos Sci Technol 69:1108–1114

McMillin CW (1973) Fibril angle of loblolly pine wood as related to specific gravity, growth rate, and distance from pith. Wood Sci Technol 7:251–255

Nanri Y, Uesaka T (1993) Dimensional stability of mechanical pulps: drying shrinkage and hygroexpansivity. Tappi J 76:62–66

Pulkkinen I, Fiskari J, Alopaeus V (2009a) The effect of hardwood fiber morphology on the hygroexpansivity of paper. BioResources 4:126–141

Pulkkinen I, Fiskari J, Alopaeus V (2009b) The effect of sample size and shape on the hygroexpansion coefficient—a study made with advanced methods for hygroexpansion measurement. Tappsa J 26–33

Sampson WW, Yamamoto J (2011) The drying shrinkage of cellulosic fibres and isotropic paper sheets. J Mater Sci 46(2):541–547

Suty S, Petrilakova K, Katuscak S, Kirschnerova S, Jablonsky M, Vizarova K, Vrska M (2012) Change in the capability of cellulose fibres to retain water during thermally accelerated ageing of paper. Cellul Chem Technol 46:631–635

Tejado A, van de Ven TGM (2010) Why does paper get stronger as it dries? Mater Today 13(9):42–49

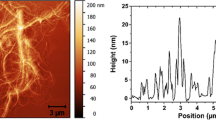

Tejado A, Chen WC, Alam MN, van de Ven TGM (2014) Superhydrophobic foam-like cellulose made of hydrophobized cellulose fibres. Cellulose 21:1735–1743

Uesaka T, Moss C (1997) Effects of fiber morphology on hygroexpansivity of paper—a micromechanics approach. In: Transactions of the fundamental research symposium, vol 1, Cambridge, pp 663–679

Uesaka T, Qi D (1994) Hygroexpansivity of paper—effects of fiber-to-fiber bonding. J Pulp Paper Sci 20:175–179

Vainio A, Sirvio M, Paulapuro H (2007) Observation on the microfibril angle of finnish papermaking fibers. In: International paper physics conference, Gold Coast, pp 397–403

Wallström L, Lindberg KAH, Johansson I (1995) Wood surface stabilization. Holz als Roh-und Werkstoff 53:87–92

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, W.C., Tejado, A., Alam, M.N. et al. Hydrophobic cellulose: a material that expands upon drying. Cellulose 22, 2749–2754 (2015). https://doi.org/10.1007/s10570-015-0645-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-015-0645-8