Abstract

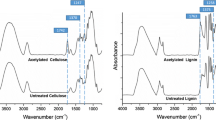

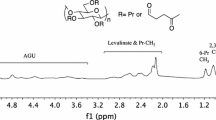

The acylation of three cellulose samples by acetic anhydride, Ac2O, in the solvent system LiCl/N,N-dimethylacetamide, DMAc (4 h, 110 °C), has been revisited in order to investigate the dependence of the reaction efficiency on the structural characteristics of cellulose, and its aggregation in solution. The cellulose samples employed included microcrystalline, MCC; mercerized cotton linters, M-cotton, and mercerized sisal, M-sisal. The reaction efficiency expresses the relationship between the degree of substitution, DS, of the ester obtained, and the molar ratio Ac2O/AGU (anhydroglucose unit of the biopolymer); 100% efficiency means obtaining DS = 3 at Ac2O/AGU = 3. For all celluloses, the dependence of DS on Ac2O/AGU is described by an exponential decay equation: DS = DSo − Ae−[(Ac2O/AGU)/B]; (A) and (B) are regression coefficients, and DSo is the calculated maximum degree of substitution, achieved under the conditions of each experiment. Values of (B) are clearly dependent on the cellulose employed: B(M-cotton) > B(M-sisal) > B(MCC); they correlate qualitatively with the degree of polymerization of cellulose, and linearly with the aggregation number, Nagg, of the dissolved biopolymer, as calculated from static light scattering measurements: (B) = 1.709 + 0.034 Nagg. To our knowledge, this is the first report on the latter correlation; it shows the importance of the physical state of dissolved cellulose, and serves to explain, in part, the need to use distinct reaction conditions for MCC and fibrous celluloses, in particular Ac2O/AGU, time, temperature.

Similar content being viewed by others

References

(1988) TAPPI Test methods—alpha-, beta- and gamma-cellulose in pulp T203 om-88

Aono H, Tamai N, Tatsumi D, Matsumoto T (2004) Aggregate structure and rheological properties of mercerized cellulose/LiCl.DMAc solution. Nihon Reoroji Gakkaishi 32:169–177; CAN 143:99099

Aono H, Tatsumi D, Matsumoto T (2006) Scaling analysis of cotton cellulose/LiCl.DMAc solution using light scattering and rheological measurements. J Polym Sci B Polym Phys 44:2155–2160

Ass BAP, Belgasem MN, Frollini E (2006) Mercerized linters cellulose: characterization and acetylation in N, N-dimethylacetamide/lithium chloride. Carbohyd Polym 63:19–29

ASTM D1795-94 (2001) Standard test methods for intrinsic viscosity of cellulose

Braun S, Berger S (2004) 200 and more basic NMR experiments: a practical course. Wiley-VCH, Weinheim, p 128

Browning BL (1967) Methods of wood chemistry, vol 2. Interscience, New York, p 499

Buchanan CM, Edgar KJ, Hyatt JA, Wilson AK (1991) Preparation of cellulose [1-carbon-13]acetates and determination of monomer composition by NMR spectroscopy. Macromolecules 24:3050–3059

Buschle-Diller G, Zeronian SH (1992) Enhancing the reactivity and strength of cotton fibres. J Appl Polym Sci 45:967–979

Carollo P, Grospietro B (2004) In: Rustemeyer P (ed) Cellulose acetates: properties and applications. Wiley-VCH, Weinheim, pp 335–351

Cheng Q, Wang S, Rials TG, Lee S-H (2007) Physical and mechanical properties of polyvinyl alcohol and polypropylene composite materials reinforced with fibril aggregates isolated from regenerated cellulose fibers. Cellulose 14:593–602

Ciacco GT, Ass BAP, Ramos LA, Frollini E (2008) Sisal, sugarcane and microcrystalline celluloses: influence of the composition of the solvent system N, N-dimethylacetamide/lithium chloride on the solubility and acetylation of these polysaccharides. E-Polym 22:1–11

Ciacco GT, Morgado DL, Frollini E, Possidonio S, El Seoud OA (2010) Some aspects of acetylation of untreated and mercerized sisal cellulose. J Brazil Chem Soc 21:71–77

Dawsey TR, McCormick CL (1990) The lithium chloride/dimethylacetamide solvent for cellulose: a literature review. JMS-Rev Macromol Chem Phys C30:405–440

Dupont A-L, Harrison G (2004) Conformation and dn/dc determination of cellulose in N, N-dimethylacetamide containing lithium chloride. Carbohy Polym 58:233–243

Edgar KJ (2007) Cellulose esters in drug delivery. Cellulose 14:49–64

Edgar KJ, Arnold KM, Blount WW, Lawniczak JE, Lowman DW (1995) Synthesis and properties of cellulose acetates. Macromolecules 28:4122–4128

Edgar KJ, Buchanan CM, Debenham JS, Rundquist PA, Seiler BD, Shelton MC, Tindall D (2001) Advances in cellulose ester performance and application. Prog Polym Sci 26:1605–1688

El Seoud OA, Heinze T (2005) Organic esters of cellulose: new perspectives for old polymers. Adv Polym Sci 186:103–149

El Seoud OA, Marson GA, Ciacco GT, Frollini E (2000) Macromol Chem Phys 201:882–889

El Seoud OA, Koschella A, Fidale LC, Dorn S, Heinze T (2007) Applications of ionic liquids in carbohydrate chemistry: a window of opportunities. Biomacromolecules 8:2639–2647

Fischer S, Thümmler K, Volkert B, Hettrich K, Schmidt I, Fischer K (2008) Properties and applications of cellulose acetate. Macromol Symp 262:89–96

Ganster J, Fink HP (2006) Novel cellulose fiber reinforced thermoplastic materials. Cellulose 13:271–280

Glasser WG (2004) Prospects for future applications of cellulose acetate. Macromol Symp 208:371–394

Hasegawa M, Isogai A, Onabe F (1993) Size-exclusion chromatography of cellulose and chitin using lithium chloride-N, N-dimethylacetamide as a mobile phase. J Chromatogr 635:334–337

Hattori K, Cuculo JA, Hudson SM (2002) New solvents for cellulose: hydrazine/thiocyanate salt system. J Polym Sci A 40:601–611

Heinze T, Hornig S (2009) Versatile concept for the structure design of polysaccharide-based nanoparticles. ACS Symp Ser 1017:169–183

Heinze T, Koehler S (2010) Dimethyl sulfoxide and ammonium fluorides—novel cellulose solvents. ACS Symp Series 1033:103–118

Henniges U, Schiehser S, Rosenau T, Potthast A (2010) Cellulose solubility: dissolution and analysis of “problematic” cellulose pulps in the solvent system DMAc/LiCl. ACS Symp Series 1033:165–177

Hiemenz PC, Lodge TP (2007) Polymer chemistry, 2nd edn. CRC Press, Boca Raton, p 659

Iwata T, Azuma J, Okamura K, Muramoto M, Chun B (1992) Preparation and NMR assignments of cellulose mixed esters regioselectively substituted by acetyl and propanoyl groups. Carbohyd Res 224:277–283

Jan S-W, Kim J-C, Chang J-H (2009) Preparation and characterization of cellulose nanocomposite films with two different organo-micas. Cellulose 16:445–454

Kowsaka K, Okajima K, Kamide K (1988) Determination of distribution of the substituent group in cellulose acetate by full assignment of all carbonyl carbon peaks of 13C [proton decoupled] NMR spectra. Polym J 20:827–836

Lennholm H, Larsson T, Iversen T (1994) Determination of cellulose Iα and Iβ in lignocellulosic material. Carbohydr Res 261:119–131

Liu D, Zhong T, Chang PR, Li K, Wu Q (2010) Starch composites reinforced by bamboo cellulosic crystals. Biores Technol 101:2529–2536

Marson GA, El Seoud OA (1999) A novel, efficient procedure for acylation of cellulose under homogeneous solution conditions. J Appl Polym Sci 74:1355–1360

Matsumoto T, Tatsumi D, Tamai N, Takaki T (2002) Solution properties of celluloses from different biological origins in LiCl/DMAc. Cellulose 8:275–282

Morgenstern B, Kammer H-W (1999) On the particulate structure of cellulose solutions. Polym 40:1299–1304

Ramos LA, Assaf JM, El Seoud OA, Frollini E (2005) Influence of supra-molecular structure and physico-chemical properties on the dissolution of celluloses in lithium chloride/N, N-dimethylacetamide solvent system. Biomacromolecules 6:2638–2647

Rinaudo M (1993) Polysaccharide characterization in relation with some original properties. J Appl Polym Sci Appl Polym Symp 52:11–17

Rinaudo M, Reguant J (2000) Polysaccharide derivatives. In: Frollini E, Leão A, Mattoso LHC (eds) Natural polymers and agro-fibers based composites. UNESP-Embrapa-USP, São Carlos, pp 15–39

Roder T, Morgenstern B, Glatter O (2000) Light-scattering studies on solutions of cellulose in N, N-dimethylacetamide/lithium chloride. Lenzinger Ber 79:97–101

Rustemeyer P (2004) In: Rustemeyer P (ed) Cellulose acetates: properties and applications. Wiley-VCH, Weinheim, pp 267–281

Sei T, Ishitani K, Suzuki R, Ikematsu K (1985) Distribution of acetyl group in cellulose acetate as determined by nuclear magnetic resonance analysis. Polym J 17:1065–1069

Sjöholm E, Gustafsson K, Pettersson B, Colmsjö A (1997) Characterization of the cellulosic residues from litium chloride/N, N-dimethylacetamide dissolution of softwood kraft pulp. Carbohydr Polym 32:57–63

Soykeabkaew N, Sian C, Saharman G, Nishino T, Peijs T (2009) All-cellulose nanocomposite by surface selective dissolution of bacterial cellulose. Cellulose 16:435–444

Striegel AM, Timpa JD (1995) Molecular characterization of polysaccharides dissolved in N, N-dimethylacetamide-lithium chloride by gel-permeation. Carbohydr Res 267:271–290

Toyoshima I (1993) In: Kennedy JF, Phillips GO, Williams PA (eds) Cellulosics: chemical, biochemical, and material aspects. Ellis Horwood, Chichester, p 125

Tshunashima Y, Hattori K (2000) Substituent distribution in cellulose acetate: its control and the effect on structure formation in solution. J Colloid Interface Sci 228:279–286

Acknowledgments

We thank the Fapesp (São Paulo State Research Foundation) for financial support and a research fellowship to D. L. Morgado; the CNPq (National Council of Scientific Research) for a research fellowship to V. C. da Silva, and research productivity fellowships to O. A. El Seoud and E. Frollini.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Ramos, L.A., Morgado, D.L., El Seoud, O.A. et al. Acetylation of cellulose in LiCl-N,N-dimethylacetamide: first report on the correlation between the reaction efficiency and the aggregation number of dissolved cellulose. Cellulose 18, 385–392 (2011). https://doi.org/10.1007/s10570-011-9496-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-011-9496-0