Abstract

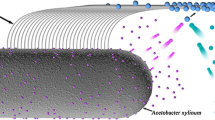

Bacterial nanocellulose (BC) is characterized by an exciting interconnection of the important and well-known cellulose properties with the outstanding features of nano-scale materials. As a remarkable benefit of BC the property-controlling fiber network and pore system formed by self-assembly of the cellulose molecules can be modified in situ using additives during biosynthesis. The addition of polyethylene glycol (PEG) 4000 causes a pore size decrease. In presence of β-cyclodextrin or PEG 400 remarkably increased pores can be achieved. Surprisingly, these co-substrates act as removable auxiliaries not incorporated in the BC samples. In contrast, carboxymethyl cellulose and methyl cellulose as additives lead to structural modified composite materials. Using cationic starch (2-hydroxy-3-trimethylammoniumpropyl starch chloride, TMAP starch) double-network BC composites by incorporation of the starch derivative in the BC prepolymer were obtained.

Similar content being viewed by others

Abbreviations

- BC:

-

Bacterial nanocellulose

- CMC:

-

Carboxymethyl cellulose

- DP:

-

Degree of polymerization

- DS:

-

Degree of substitution

- DSC:

-

Differential scanning calorimetry

- DSMZ:

-

Deutsche Sammlung von Mikroorganismen und Zellkulturen

- GlcNAc:

-

N-Acetyl glucosamine

- GPC:

-

Gel permeation chromatography

- HS:

-

Hestrin-Schramm

- MC:

-

Methyl cellulose

- MN :

-

Number molecular weight

- MW :

-

Weight molecular weight

- PDI:

-

Polydispersity

- PEG/PEO:

-

Polyethylene glycol

- SEM:

-

Scanning electron microscopy

- TMAP starch:

-

2-hydroxy-3-trimethylammoniumpropyl starch chloride

- UDP glucose:

-

uridine diphosphate glucose

- WHC:

-

Water holding capacitiy

References

Astley OM, Chanliaud E, Donald AM, Gidley MJ (2001) Structure of Acetobacter cellulose composites in the hydrated state. Int J Biol Macromol 29:193–202. doi:10.1016/S0141-8130(01)00167-2

Brown EE, Laborie M-PG (2007) Bioengineering bacterial cellulose/poly(ethylene oxide) nanocomposites. Biomacromolecules 8:3074–3081. doi:10.1021/bm700448x

Brown EE, Laborie M-PG (2008) Additions & corrections: bioengineering bacterial cellulose/poly(ethylene oxide) nanocomposites. Biomacromolecules 9:3427–3428. doi:10.1021/bm8012023

Delmer DP, Benzimann M, Klein AS, Bacic A, Mitchell B, Weinhouse H, Aloni Y, Callaghan T (1983) A comparison of the mechanism of cellulose biosynthesis in plants and bacteria. J Appl Polym Sci Symp 37:1–16

Haak V, Heinze T, Oelmeyer G, Kulicke W-M (2002) Starch derivatives of high degree of functionalization, synthesis and flocculation behavior of cationic starch polyelectrolytes. Macromol Mater Eng 287:495–502. doi:10.1002/1439-2054(20020801)287:8<495::AID-MAME495>3.0.CO;2-K

Haigler CH, White AR, Brown AR Jr, Cooper KM (1982) Alteration of in vivo cellulose ribbon assembly by carboxymethylcellulose and other cellulose derivatives. J Cell Biol 94:64. doi:10.1083/jcb.94.1.64

Heßler N (2004) Synthese von requellbarer sowie kurzkettiger Bakteriencellulose. Diploma thesis, Friedrich-Schiller-Universität, Jena

Hestrin S, Schramm M (1954) Synthesis of cellulose by Acetobacter xylinum II. Preparation of freeze-dried cells capable of polimerizing glucose to cellulose. Biochem J 58:345–352

Hibino Y, Sato T, Kaji H, Ougiya H, Watanabe K, Hioki S (1998) Manufacture of bacterial cellulose-containing paper with high filler retention. JP Patent 10273891

Jayme G, Rothamel L (1948) Development of a standard centrifugal method for determining the swelling values of pulps. Papier Bingen Ger 2:7–18

Klemm D, Schumann D, Udhardt U, Marsch S (2001) Bacterial synthesized cellulose–artifical blood vessels for microsurgery. Prog Polym Sci 26:1561–1603. doi:10.1016/S0079-6700(01)00021-1

Klemm D, Heublein B, Fink H-P, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem Int Ed 44:3358–3393. doi:10.1002/anie.200460587

Klemm D, Schumann D, Kramer F, Hessler N, Hornung M, Schmauder H-P, Marsch S (2006) Nanocelluloses as innovative polymers in research and application. Adv Polym Sci 205:49–96. doi:10.1007/12_097

Okazaki N (1999) Low-density paper containing bacteria cellulose and expandable particles with high tensile strength and manufacture thereof. JP Patent 11200282

Sakairi N, Suzuki S, Ueno K, Han S-M, Nishi N, Tokura S (1998) Biosynthesis of heteropolysaccharides by Acetobacter xylinum—synthesis and characterization of metal-ion adsorptive properties of partially carboxymethylated cellulose. Carbohydr Polym 37:409–414. doi:10.1016/S0144-8617(97)00226-9

Schumann D, Klemm DO, Kramer F, Wesarg F, Koth D, Fried W (2008) Artificial vascular implants from bacterial synthesized cellulose. Abstracts of Papers, 235th ACS national meeting, New Orleans, LA, United States

Seifert M, Hesse S, Kabrelian V, Klemm D (2004) Controlling the water content of never dried and reswollen bacterial cellulose by the addition of water-soluble polymers to the culture medium. J Polym Sci 42(A1):463–470

Smith BA, Colegrove GT, Rakitsky WG (1999) Acid-stable and cationic-compatible cellulose compositions and their manufacture. WO Patent 9940153

Yano H, Sugiyama J, Nakagaito AN, Nogi M, Matsuura T, Hikita M, Handa K (2005) Optically transparent composites reinforced with networks of bacterial nanofibers. Adv Mater 17:153–155. doi:10.1002/adma.200400597

Acknowledgments

Among many colleagues from the Institute of Organic and Macromolecular Chemistry as well as the lab, authors are especially grateful to Dr. Tim Liebert for the production of TMAP starch. We thank Dr. Völksch for SEM investigations and Mrs. Weiß for DSC measurements. Special thanks go to Prof. Antje Potthast (Department of Chemistry, University of natural resources and applied life sciences, Vienna)for the GPC investigations.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Heßler, N., Klemm, D. Alteration of bacterial nanocellulose structure by in situ modification using polyethylene glycol and carbohydrate additives. Cellulose 16, 899–910 (2009). https://doi.org/10.1007/s10570-009-9301-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-009-9301-5