Abstract

The oxidation of cyclohexane via the in-situ production of H2O2 from molecular H2 and O2 offers an attractive route to the current industrial means of producing cyclohexanone and cyclohexanol (KA oil), both key materials in the production of Nylon. Herein we demonstrate that through the in-situ production of H2O2 supported AuPd nanoparticles catalyse the formation of KA oil under conditions where activity is limited when using molecular O2, with no loss in catalytic activity observed upon re-use. The effect of key reaction parameters, including reaction temperature, catalyst mass and H2:O2 ratio are evaluated.

Graphic Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The oxidation of cyclohexane and production of cyclohexanone and cyclohexanol (collectively known as KA oil) is a key industrial process in the production of adipic acid and caprolactam, which in turn are starting materials for Nylon-6,6 and Nylon-6. The current industrial means of producing KA oil via the high temperature (> 150 °C) aerobic oxidation of cyclohexane typically utilises homogeneous cobalt salts and limits conversion to below 5% in order to maintain high selectivity towards desired products. Initially cyclohexyl hydroperoxide (CHHP) is the major product that decomposes to form cyclohexanone and cyclohexanol, with carboxylic acids also produced [1, 2]. At higher conversion rates significant amounts of ring-opened by-products, such as 6-hydroxyhexanoic acid, in addition to a range of C1–C5 (di)acids are produced [3]. In addition to the high energy costs associated with the use of elevated temperatures the difficulties associated with separation of the catalyst from product streams has driven significant research into the replacement of cobalt salts with heterogeneous catalysts, with immobilised precious metal catalysts of particular interest [4,5,6]. While further studies have reported that significantly lower reaction temperatures can be utilised by replacing molecular O2 with tert-butylhydroperoxide [7,8,9] or pre-formed H2O2, although it should be noted that H2O2 efficiency is typically limited [10, 11], often due to catalysed H2O2 decomposition [12,13,14].

Furthermore, several economic and environmental drawbacks associated with the use of commercial H2O2 exist, namely those associated with the anthraquinone oxidation (AO) process, the means by which the vast majority of H2O2 is produced on an industrial scale. Despite the high efficiency of the AO process it is only economically viable when operated at a large scale, necessitating the centralisation of production [15]. Hence, H2O2 is typically transported and stored at concentrations in excess of 70 wt% prior to dilution at point of final use. While the low stability of H2O2, undergoing rapid decomposition in the presence of relatively mild temperatures, requires the use of stabilising agents such as acetic acid [16] or phosphoric acid [17]. With the use of such additives often passing on additional costs to the end user, associated with reactor corrosion and their removal from product streams.

Therefore, the in-situ production of H2O2 from molecular H2 and O2 would offer an attractive alternative for the selective oxidation of cyclohexane, avoiding the numerous drawbacks associated with the use of pre-formed H2O2. In particular the use of in-situ produced H2O2 would lead to significantly reduced process costs, associated with lower reaction temperatures and the use of cheaper reaction feeds, namely H2 and O2.

2 Experimental

2.1 Catalyst Preparation

Bi-metallic 0.5% Au–0.5% Pd/TiO2 catalysts have been prepared (on a weight basis) by a conventional wet-impregnation procedure, based on methodology previously reported in the literature [18]. Catalysts produced via a wet-impregnation procedure have been widely studied due to simplicity and ease with which this approach can be scaled to meet industrial application. The procedure to produce 0.5% Au–0.5% Pd/TiO2 (2 g) is outlined below, with a similar methodology utilized for all mono- and bi-metallic catalysts.

Aqueous acidified PdCl2 solution (1.667 mL, 6 mg mL–1, Sigma-Aldrich) and aqueous HAuCl4·3H2O solution (0.8263 mL, 12.25 mg mL–1, Strem Chemicals) were mixed in a 50 mL round-bottom flask and heated to 65 °C with stirring (1000 rpm) in a thermostatically controlled oil bath, with total volume fixed to 16 mL using H2O (HPLC grade). Upon reaching 65 °C, TiO2 (1.98 g, Degussa, P25) was added over the course of 5 min with constant stirring. The resulting slurry was stirred at 65 °C for a further 15 min, following this the temperature was raised to 95 °C for 16 h to allow for complete evaporation of water. The resulting solid was ground prior to calcination (static air, 400 °C, 3 h, 20 °C min–1). We have previously demonstrated that calcination of supported AuPd catalysts at a temperature of 400 °C is required to produce a highly active, stable catalyst and results in the adoption of Au-core PdO-shell nanoparticle morphology when using a range of oxide supports [19].

2.2 Catalyst Testing

Note: reaction conditions used within this study operate under the flammability limits of gaseous mixtures of H2 and O2.

2.3 Direct Synthesis of H2O2 from H2 and O2

Hydrogen peroxide synthesis was evaluated using a Parr Instruments stainless steel autoclave with a nominal volume of 50 mL, equipped with a PTFE liner and a maximum working pressure of 14 MPa. To test each catalyst for H2O2 synthesis, the autoclave liner was charged with catalyst (0.01 g) and solvent (5.6 g methanol and 2.9 g H2O). The charged autoclave was then purged three times with 5% H2/CO2 (100 psi) before filling with 5% H2/CO2 to a pressure of 420 psi, followed by the addition of 25% O2/CO2 (160 psi). Pressure of 5% H2/CO2 and 25% O2/CO2 are given as gauge pressures. The reaction was conducted at a temperature of 20 °C, for 0.5 h with stirring (1200 rpm). Reactor temperature was controlled using a HAAKE K50 bath/circulator using an appropriate coolant.

H2O2 productivity was determined by titrating aliquots of the final solution after reaction with acidified Ce(SO4)2 (0.0085 M) in the presence of ferroin indicator. Catalyst productivities are reported as \({\text{mol}}_{{{\text{H}}_{{2}} {\text{O}}_{{2}} }} \,{\text{kg}}_{{{\text{cal}}}}^{ - 1} \,{\text{h}}^{{ - {1}}}\).

2.4 Cyclohexane Oxidation via the In-Situ Production of H2O2

Cyclohexane oxidation has been evaluated using a Parr Instruments stainless steel autoclave with a nominal volume of 50 mL, equipped with a PTFE liner and a maximum working pressure of 14 MPa. To test each catalyst for cyclohexane oxidation, the autoclave was charged with catalyst (0.05 g), t-butanol solvent (6.375 g, Sigma Aldrich) and cyclohexane (2.125 g, 25 mmol, Sigma Aldrich) with mesitylene (0.43 g, Sigma Aldrich) used as an internal standard. The charged autoclave was then purged three times with 5% H2/N2 (0.7 MPa) before filling with 5% H2/N2 to a pressure of 2.9 MPa, (2.51 mmol H2) followed by the addition of 25% O2/CO2 (1.1 MPa, 4.77 mmol O2). The temperature was then increased to 80 °C with stirring (500 rpm). Once the desired temperature was reached the reaction mixture was stirred (1200 rpm) for 17 h. After the reaction was complete the reactor was cooled in ice to a temperature of 15 °C, upon which a gas sample was taken for analysis by gas chromatography, using a Varian CP-3380 equipped with a TCD detector and a Porapak Q column. Product yield was determined by gas chromatography using a Varian 3200 GC equipped with a FID and CP Wax 42 column.

Quantification of the peroxide intermediate cyclohexyl hydroperoxide (CHHP) is determined by reacting a 2 mL aliquot of the post reaction mixture with an excess of triphenyl phosphine (0.13 g, 0.5 mmol). Reaction of triphenyl phosphine and CHHP produces cyclohexanol and hence comparison of GC analysis for cyclohexanol pre and post treatment with triphenyl phosphine can determine the yield of CHHP.

Catalytic conversion of H2 was determined using a Varian 3800 GC fitted with TCD and equipped with a Porapak Q column.

H2 conversion (Eq. 1), cyclohexane conversion (Eq. 2) and selectivity to all C6 products based on H2 (Eq. 3) is defined as follows:

Note Given the relatively low conversion rates observed within this work total product yield is used as a substitute for cyclohexane conversion.

2.5 Catalyst Reusability in the Oxidation of Cyclohexane via In-Situ Production of H2O2

In order to determine catalyst reusability, a similar procedure to that outlined above for the oxidation of cyclohexane is followed utilising 0.15 g of catalyst. Following the initial test, the catalyst was recovered by filtration, washed with cyclohexane and dried (30 °C, 17 h, under vacuum); from the recovered catalyst sample 0.05 g was used to conduct a standard cyclohexane oxidation experiment.

2.6 Catalyst Characterisation

A Thermo Scientific K-Alpha+ photoelectron spectrometer was used to collect XP spectra utilising a micro-focused monochromatic Al Kα X-ray source operating at 72 W. Data was collected over an elliptical area of approximately 400 μm2 at pass energies of 40 and 150 eV for high-resolution and survey spectra, respectively. Sample charging effects were minimised through a combination of low energy electrons and Ar+ ions, consequently this resulted in a C(1s) line at 284.8 eV for all samples. All data was processed using CasaXPS v2.3.20 rev 1.2H using a Shirley background, Scofield sensitivity factors [19] and an electron energy dependence of − 0.6 as recommended by the manufacturer.

Transmission electron microscopy (TEM) was performed on a JEOL JEM-2100 operating at 200 kV. Samples were prepared by dispersion in ethanol by sonication and deposited on 300 mesh copper grids coated with holey carbon film. Energy dispersive X-ray analysis (EDX) was performed using an Oxford Instruments X-MaxN 80 detector and the data analysed using the Aztec software.

Metal leaching was quantified using microwave plasma-atomic emission spectroscopy (MP-AES). Post reaction solid catalysts were digested (0.01 g catalyst in 10 mL aqua-regia, 16 h) prior to analysis using an Agilent 4100 MP-AES.

3 Results and Discussion

Our initial studies investigated the efficacy of mono- and bi-metallic 1% AuPd/TiO2 catalysts, prepared by a conventional wet-impregnation procedure, towards the direct synthesis of H2O2 from molecular H2 and O2 under reaction conditions not conducive towards H2O2 stability (Fig. S1). In keeping with our previous studies into the direct synthesis of H2O2 [20] as well as a range of selective oxidation reactions [21,22,23,24], the alloying of Au with Pd results in a synergistic enhancement in catalytic activity, with the 0.5% Au–0.5% Pd/TiO2 catalyst demonstrating far greater activity towards H2O2 formation than the mono-metallic analogues.

We have previously demonstrated that it is possible to catalyse the oxidation of cyclohexane via the in-situ production of H2O2, with AuPd nanoparticles immobilised onto zeolite-Y demonstrating appreciable rates of cyclohexane conversion (2.4%) and product yield (74 µmol) [25]. Interestingly these previous studies reported complete selectivity towards cyclohexanol, likely as a result of the short reaction times utilised.

Building on our initial results we next investigated catalytic efficacy towards cyclohexane oxidation, via the in-situ production of H2O2 (Fig. 1). It should be noted that under the reaction conditions used within this study no residual H2O2 was measured in post reaction solutions. This is perhaps unsurprising given the comparatively high reaction temperatures and long reaction times utilised within this study. However, our previous studies, have elucidated the ability of H2O2 to be synthesised under similar reaction conditions [25]. It can be seen that the activity of the 0.5% Au–0.5% Pd/TiO2 (12.8 µmol) catalyst greatly outperforms the analogous monometallic 1% Au/TiO2 (6.8 µmol) and 1% Pd/TiO2 (3.6 µmol) catalysts. A physical mixture of the 1% Au/TiO2 and 1% Pd/TiO2 catalysts demonstrated considerably lower activity (1.3 µmol) than that of the bi-metallic catalyst indicating the need for Au and Pd to be present as an alloyed species or in close proximity on the same support grain to achieve a synergistic enhancement in catalytic activity.

Catalytic activity of AuPd supported catalysts towards the oxidation of cyclohexane. Reaction conditions Catalyst (0.05 g), cyclohexane (2.13 g, 25 mmol), t-butanol (6.37 g), 5% H2/N2 (420 psi), 25% O2/N2 (160 psi), 17 h, 80 °C 1200 rpm. Note In the case of a physical mixture of the monometallic catalysts 0.025 g of each catalyst is used

Importantly the activity of the 0.5% Au–0.5% Pd/TiO2 catalyst under in-situ conditions (i.e. in the presence of H2 and O2) greatly outperforms that observed using O2 and is comparable to that seen when using preformed H2O2 (Fig. S2), clearly highlighting the benefits of the in-situ approach. This can be understood when considering the relatively low reaction temperatures utilised in this study, compared to that typically required when using O2 as an oxidant and the low stability of preformed H2O2, even at these mild temperatures.

Building on these promising initial results, and in an attempt to improve catalytic activity we next investigated the effect of a range of reaction conditions on the selective oxidation of cyclohexane. Time-on-line analysis was first evaluated (Fig. 2), in keeping with previous studies into the selective oxidation of cyclohexane [4, 26, 27] and cyclohexene [28] a clear induction period is observed, with no conversion of cyclohexane observed up to 3 h. Beyond which total product yield gradually increases to a maxima of 18.6 µmol over the time period studied. It should be noted that no conversion of cyclohexane is observed under similar reaction conditions utilising molecular O2 alone (Fig. S2). Under both aerobic and in-situ conditions we do not observe the formation of any products other than KA oil and CHHP, such as adipic acid. This is not unsurprising given the relatively mild conditions used within this work, with the production of adipic acid on an industrial scale catalysed by high concentrations of HNO3. Analysis of H2 and cyclohexane conversion, in addition to selectivity to all C6 products (cyclohexanone, cyclohexanol and CHHP) can be seen in Table S1 and reveals that H2 conversion is particularly high (68%) even at short reaction times, with this metric increasing with time to near complete conversion over 24 h. In a similar manner cyclohexane conversion increases with reaction time. However, it should be noted that the extent of cyclohexane conversion is particularly low in all cases (< 1%). This may be unsurprising given the vast excess of cyclohexane (25 mmol) present in comparison to H2 (2.51 mmol). Given the limited product yield observed a reaction time of 17 h was chosen to evaluate other key reaction parameters.

Catalytic activity towards the selective oxidation of cyclohexane, via H2O2 synthesis as a function of reaction time over a 0.5% Au–0.5% Pd/TiO2 catalyst. Reaction conditions Catalyst (0.05 g), cyclohexane (2.13 g, 25 mmol), t-butanol (6.37 g), 5% H2/N2 (420 psi), 25% O2/N2 (160 psi), 80 °C 1200 rpm

XPS analysis of the 0.5% Au–0.5% Pd/TiO2 catalyst at key time intervals (Table 1) reveals a stark shift in Pd: Au, possibly indicative of nanoparticle restructuring or agglomeration during the course of the reaction. With the possibility of agglomeration supported by TEM analysis of the fresh and used 0.5% Au–0.5% Pd/TiO2 catalyst (representative micrographs seen in Fig. S3). Although it should be noted that it was not possible to count a statistically relevant number of nanoparticles to generate an accurate mean particle size for the fresh and used catalysts. Perhaps more interesting is the significant increase in Pd0: Pd2+ ratio over the course of the reaction, with this value increasing from a value of 1.3 for the as prepared material to 9.8 after use in a 24 h reaction, likely due to the in-situ reduction of Pd2+.

The effect of varying reaction temperature was next studied (Fig. 3). While numerous studies have reported the beneficial effect of sub-ambient temperatures on the direct synthesis of H2O2, owing to an inhibition of H2O2 degradation pathways [15, 29], typically temperatures exceeding 140 °C have been explored for the oxidation of cyclohexane under aerobic conditions [30] as such a large conditions gap exists between the two key reaction steps. Temperatures between 50 and 140 °C were evaluated for cyclohexane oxidation via the in-situ production of H2O2, with the results shown in Fig. 3a (comparative data using molecular O2 as the oxidant seen in Fig. 3b). Below the autooxidation temperature of 140 °C conversion of cyclohexane using O2 alone is limited, with a significant improvement in total product yield observed through combining H2 and O2. Indeed, at temperatures below 80 °C no products are observed under purely aerobic conditions, highlighting the beneficial role of H2O2 production in the oxidation of cyclohexane.

The effect of reaction temperature on the oxidation of cyclohexane to KA oil over a 0.5% Au–0.5% Pd/TiO2 catalysts (a) using in-situ generated H2O2 and (b) using molecular O2 as the oxidant. Reaction conditions Catalyst (0.05 g), cyclohexane (2.13, 25 mmol), t-butanol (6.37 g), 5% H2/N2 (420 psi), 25% O2/N2 (160 psi), 17 h, 80 °C 1200 rpm. Note When using O2 as oxidant 25%O2/N2 (160 psi) is used and N2 (420 psi)

The effect of catalyst mass was next investigated (Fig. 4) with total product yield increasing steadily with catalyst content up to a catalyst mass of 0.05 g (12.8 µmol). Beyond which a significant decrease in product yield, in addition to product selectivity (Table S2) is observed, likely due to increased catalytic activity towards H2O2 degradation and H2O formation (via hydrogenation and decomposition pathways) with a similar mass dependence previously reported for the direct synthesis of H2O2 [31]. This is supported by H2 conversion analysis (Table S2) which indicates minimal difference in H2 conversion rates beyond a catalyst mass of 0.01 g. Alongside the significantly lower product yields at higher catalyst masses this suggests H2 is utilised unselectively in the hydrogenation of H2O2.

Investigation into the effect of stirring rate was next carried out (Fig. 5) with an optimal stirring speed of 1200 rpm determined. Below this stirring rate it is considered that the reactants are not sufficiently mixed, and the reaction is limited by reactant diffusion, while at stirring speeds exceeding 1200 rpm the reaction is inhibited by cavitation, where available catalytic sites are limited due to centrifugal forces (see Schematic S1) [32]. Determination of H2 conversion and cyclohexane conversion (Table S.3) reveals a similar trend to that seen for total product yield, with these metrics reaching a maxima at 1200 rpm (94% H2 conversion and 0.05% cyclohexane conversion), before decreasing at increased stirring speed (78% H2 conversion and 0.03% cyclohexane conversion at 1400 rpm) indicating that H2O2 production and in turn cyclohexane oxidation is limited at increased stirring speeds.

Catalytic activity towards the selective oxidation of cyclohexane, via H2O2 synthesis as a function of stirring speed over a 0.5% Au–0.5% Pd/TiO2 catalyst. Reaction conditions Catalyst (0.05 g), cyclohexane (2.13 g, 25 mmol), t-butanol (6.37 g), 5% H2/N2 (420 psi), 25% O2/N2 (160 psi), 17 h, 80 °C 1200 rpm

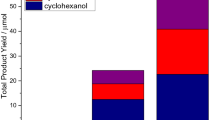

The effect of H2:O2 ratio was next investigated, while maintaining total reaction pressure at 580 psi (Fig. 6). A clear enhancement in KA oil yield is observed, with this metric increasing to a value of 47.6 µmol under H2-rich conditions (H2:O2 = 3.8). This is perhaps unsurprising given the first order dependence of H2O2 synthesis with respect to H2, while there is a zero order dependence with respect to O2 [33]. As such, at low H2:O2 ratios, where the reaction is limited by H2 availability, H2O2 production and in turn cyclohexane oxidation is limited.

Finally, with the requirement to re-use a catalyst successfully at the heart of green chemistry we next investigated catalytic activity of the 0.5% Au–0.5% Pd/TiO2 catalyst towards cyclohexane oxidation upon re-use (Fig. 7), with previous studies reporting the high stability of supported AuPd nanoparticles for the oxidation of cyclohexane using molecular O2 [24].

Interestingly, it is possible to observe that catalytic activity increases substantially with re-use of the catalyst, with total product yield increasing from 9.0 µmol for the fresh catalyst to 19.1 µmol upon the third use. X-ray photoelectron spectroscopic analysis of the fresh and used catalysts (Table 2) reveals a significant shift in Pd oxidation state with use. As expected, given the exposure to an oxidative heat treatment (3 h, 400 °C, static air) the fresh 0.5% Au–0.5% Pd/TiO2 catalyst is observed to predominantly consist of Pd2+. Indeed, we have previously demonstrated that upon calcination a Au-core Pd-shell nanoparticle morphology is typically adopted for AuPd catalysts supported on TiO2, with the adoption of this morphology often related to enhanced catalytic performance [20].

Upon sequential re-use in the cyclohexane oxidation reaction the Pd oxidation state is seen to shift, to consist entirely of Pd0, likely as a result of in-situ reduction of Pd2+ species. The enhanced activity of reduced Pd-species towards the direct synthesis of H2O2 is well known, with Burch and Ellis [34] and Liu et al. [35] reporting higher H2O2 production rates over supported Pd0 catalysts compared to Pd2+ analogues. As such it is possible to correlate the increase in KA oil production to an enhancement in Pd0 content.

Interestingly a stark shift in Pd: Au ratio is also observed with no Au signal detected after the catalyst is used in the cyclohexane oxidation reaction. With MP-AES analysis of the digested fresh and used 0.5% Au–0.5% Pd/TiO2 catalysts revealing the high stability of the catalyst (Table S4) it is possible to rule out Au leaching as the factor responsible for the loss of observable Au in our XPS analysis.

Further study of the fresh and used catalysts via TEM (representative micrographs seen in Fig. S3) reveals that a bimodal distribution of nanoparticle size exists in the fresh catalyst, with similar findings by Herzing et al. [36] and Edwards et al. [37] previously reported for supported AuPd catalysts prepared by an analogous wet impregnation methodology. Indeed, detailed STEM-XEDS analysis has previously revealed a distinct relationship between particle size and elemental composition, with larger nanoparticles found to be Au-rich, while smaller nanoparticles are Pd-rich [37]. Upon use in the cyclohexane oxidation reaction a substantial loss of the small, presumably Pd-rich nanoparticles is observed, with the resulting formation of larger AuPd agglomerates, presumably the likely cause for the loss of Au signal in our analysis by XPS. Previous studies by Williams et al. have highlighted the enhanced catalytic performance of larger AuPd nanoparticles for the selective oxidation of methane, using preformed H2O2 [38]. With this previous study in mind it is therefore possible to conclude that a combination of increased particle size and the formation of reduced Pd species are responsible for the enhanced activity observed upon re-use.

4 Conclusion

We have demonstrated that it is possible to achieve significant rates of cyclohexane oxidation to KA oil using H2O2 generated in-situ using a 1% AuPd/TiO2 catalyst, prepared by a readily scalable wet-impregnation procedure. This is observed using conditions where activity is limited when using molecular O2, with no loss in catalytic activity observed with re-use. We consider that these catalysts represent a promising basis for further exploration for the selective oxidation of a range of feed stocks.

Data Availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Hamann JS, Hermsen M, Schmidt A-C, Kreig S, Schießl J, Riedel D, Teles JH, Schäfer A, Comba P, Hashmi ASK, Schaub T (2018) Selective Decomposition of cyclohexyl hydroperoxide using homogeneous and heterogeneous CrVI catalysts: optimizing the reaction by evaluating the reaction mechanism. ChemCatChem 10:2755–2767

Peixoto de Almeida M, Martins LMDRS, Carabineiro SAC, Lauterbach T, Rominger F, Hashmi ASK, Pombeiro AJL, Figueiredo JL (2013) Homogeneous and heterogenised new gold C-scorpionate complexes as catalysts for cyclohexane oxidation. Catal Sci Technol 3:3056–3069

Hermans I, Jacobs PA, Peeters J (2006) To the core of autocatalysis in cyclohexane autoxidation. Chem Eur J 12:4229–4240

Xu Y-J, Landon P, Enache D, Carley AF, Roberts MW, Hutchings GJ (2005) Selective conversion of cyclohexane to cyclohexanol and cyclohexanone using a gold catalyst under mild conditions. Catal Lett 101:175–179

Carabineiro SAC, Martins LMDRS, Avalos-Borja M, Buijnsters JG, Pombeiro AJL, Figueiredo JL (2013) Gold nanoparticles supported on carbon materials for cyclohexane oxidation with hydrogen peroxide. Appl Catal A 467:279–290

Xu L-X, He C-H, Zhu M-Q, Wu K-J, Lai Y-L (2008) Surface stabilization of gold by sol–gel post-modification of alumina support with silica for cyclohexane oxidation. Catal Commun 9:816–820

Khare S, Shrivastava P (2016) Solvent-free oxidation of cyclohexane over covalently anchored transition-metal salicylaldimine complexes to α-zirconium phosphate using tert-butylhydroperoxide. J Mol Catal A: Chem 411:279–289

Pires EL, Magalhães JC, Schuchardt U (2000) Effects of oxidant and solvent on the liquid-phase cyclohexane oxidation catalyzed by Ce-exchanged zeolite Y. Appl Catal A 203:231–237

Denicourt-Nowicki A, Lebedeva A, Bellini C, Roucoux A (2016) Highly selective cycloalkane oxidation in water with ruthenium nanoparticles. ChemCatChem 8:357–362

Santra C, Shah S, Mondal A, Pandey JK, Panda AB, Maity S, Chowdhury B (2016) Synthesis, characterization of VPO catalyst dispersed on mesoporous silica surface and catalytic activity for cyclohexane oxidation reaction. Microporous Mesoporous Mater 223:121–128

Du Y, Xiong Y, Li J, Yang X (2009) Selective oxidation of cyclohexane with hydrogen peroxide in the presence of copper pyrophosphate. J Mol Catal A: Chem 298:12–16

Armengol E, Corma A, Fornés V, Garcia H, Primo J (1999) Cu2+-phthalocyanine and Co2+-perfluorophthalocyanine incorporated inside Y faujasite and mesoporous MCM-41 as heterogeneous catalysts for the oxidation of cyclohexane. Appl Catal A 181:305–312

Carvalho WA, Wallau M, Schuchardt U (1999) Iron and copper immobilised on mesoporous MCM-41 molecular sieves as catalysts for the oxidation of cyclohexane. J Mol Catal A: Chem 144:91–99

Spinace EV, Pastore HO, Schuchardt U (1995) Cyclohexane Oxidation catalyzed by titanium silicalite (TS-1): overoxidation and comparison with other oxidation systems. J Catal 157:631–635

Crole DA, Freakley SJ, Edwards JK, Hutchings GJ (2016) Direct synthesis of hydrogen peroxide in water at ambient temperature. Proc R Soc A 472:20160156

Scoville JR, Novicova IA (1996) Hydrogen peroxide disinfecting and sterilizing compositions. US5900256

Wegner P (2003) Hydrogen peroxide stabilizer and resulting product and applications. US20050065052A1

Lewis RJ, Ueura K, Fukuta Y, Freakley SJ, Kang L, Wang R, He Q, Edwards JK, Yamamoto MDJ, Hutchings GJ (2019) The direct synthesis of H2O2 using TS-1 supported catalysts. ChemCatChem 11:1673–1680

Scofield JH (1976) Hartree–Slater subshell photoionization cross-sections at 1254 and 1487 eV. J Electron Spectrosc Relat Phenom 8:129–137

Edwards JK, Solsona BE, Landon P, Carley AF, Herzing A, Kiely CJ, Hutchings GJ (2005) Direct synthesis of hydrogen peroxide from H2 and O2 using TiO2-supported Au–Pd catalysts. J Catal 236:69–79

Wu P, Cao Y, Zhao L, Wang Y, He Z, Xing W, Bai P, Mintova S, Yan Z (2019) Formation of PdO on Au–Pd bimetallic catalysts and the effect on benzyl alcohol oxidation. J Catal 375:32–43

Agarwal N, Freakley SJ, McVicker RU, Althaban SM, Dimitratos N, He Q, Morgan DJ, Jenkins RL, Willock DJ, Taylor SH, Kiely CJ, Hutchings GJ (2017) Aqueous Au–Pd colloids catalyze selective CH4 oxidation to CH3OH with O2 under mild conditions. Science 358:223–227

Bianchi CL, Canton P, Dimitratos N, Porta F, Prati L (2005) Selective oxidation of glycerol with oxygen using mono and bimetallic catalysts based on Au. Pd and Pt metals Catal Today 102–103:203–212

Liu X, Conte M, Sankar M, He Q, Murphy DM, Morhan DJ, Jenkins RL, Knight D, Whiston K, Kiely CJ, Hutchings GJ (2015) Liquid phase oxidation of cyclohexane using bimetallic Au–Pd/MgO catalysts. Appl Catal A 504:373–380

Li G, Edwards J, Carley AF, Hutchings GJ (2007) Direct synthesis of hydrogen peroxide from H2 and O2 and in situ oxidation using zeolite-supported catalysts. Catal Commun 8:247–250

Zhao R, Ji D, Gaomeng L, Yan L, Wang X, Suo J (2004) A highly efficient oxidation of cyclohexane over Au/ZSM-5 molecular sieve catalyst with oxygen as oxidant. Chem Commun 2:904–905

Lü G, Zhao R, Qian G, Oi Y, Wang X, Suo J (2004) A highly efficient catalyst Au/MCM-41 for selective oxidation cyclohexane using oxygen. Catal Lett 97:115–118

Alfayate A, Márquez-Álvarez C, Grande-Casas M, Bernardo-Maestro S-S, Perez-Pariente J (2013) Enhanced catalytic activity of TAPO-5 in the oxidation of cyclohexene with hydrogen peroxide under anhydrous conditions. Catal Today 213:211–218

Santos A, Lewis RJ, Malta G, Howe AGR, Morgan DJ, Mapton E, Gaskin P, Hutchings GJ (2019) Direct synthesis of hydrogen peroxide over Au–Pd supported nanoparticles under ambient conditions. Ind Eng Chem Res 58:12623–12631

Huang G, Guo C-C, Tang S-S (2007) Catalysis of cyclohexane oxidation with air using various chitosan-supported metallotetraphenylporphyrin complexes. J Mol Catal A: Chem 261:125–130

Landon P, Collier PJ, Carley AF, Chadwick D, Papworth AJ, Burrows A, Kiely CJ, Hutchings GJ (2003) Direct synthesis of hydrogen peroxide from H2 and O2 using Pd and Au catalysts. Phys Chem Chem Phys 5:1917–1923

Piccinini M, Edwards JK, Moulijn JA, Hutchings GJ (2012) Influence of reaction conditions on the direct synthesis of hydrogen peroxide over AuPd/carbon catalysts. Catal Sci Technol 2:1908–1913

Liu Q, Bauer JC, Schaak RE, Lunsford JH (2008) Direct synthesis of H2O2 from H2 and O2 over Pd–Pt/SiO2 bimetallic catalysts in a H2SO4/ethanol system. Appl Catal A 339:130–136

Burch R, Ellis PR (2003) An investigation of alternative catalytic approaches for the direct synthesis of hydrogen peroxide from hydrogen and oxygen. Appl Catal B 42:203–211

Liu Q, Gath KK, Bauer JC, Schaak LJH (2009) The active phase in the direct synthesis of H2O2 from H2 and O2 over Pd/SiO2 catalyst in a H2SO4/ethanol system. Catal Lett 132:342

Herzing AA, Watanabe M, Edwards JK, Conte M, Tang Z-R, Hutchings GJ, Kiely CJ (2008) Energy dispersive X-ray spectroscopy of bimetallic nanoparticles in an aberration corrected scanning transmission electron microscope. Faraday Discuss 138:337–351

Edwards JK, Carley AF, Herzing AA, Kiely CJ, Hutchings GJ (2008) Direct synthesis of hydrogen peroxide from H2 and O2 using supported Au–Pd catalysts. Faraday Discuss 138:225–239

Williams C, Carter JH, Dummer NF, Chow YK, Morgan DJ, Yacob S, Serna P, Willock DJ, Meyer RJ, Taylor SH, Hutchings GJ (2018) Selective oxidation of methane to methanol using supported AuPd catalysts prepared by stabilizer-free sol-immobilization. ACS Catal 8:2567–2576

Acknowledgements

The authors with to acknowledge the financial support of and research discussion with Haldor Topsøe and the Cardiff University electron microscope facility for the transmission electron microscopy.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Caitlin M. Crombie and Richard J. Lewis have contributed equally to this work.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Crombie, C.M., Lewis, R.J., Kovačič, D. et al. The Influence of Reaction Conditions on the Oxidation of Cyclohexane via the In-Situ Production of H2O2. Catal Lett 151, 164–171 (2021). https://doi.org/10.1007/s10562-020-03281-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-020-03281-1