Abstract

The mechanism of N2O decomposition on the platinum and copper loaded carbon film catalysts was studied using in situ FTIR spectroscopy at the temperature range 200–600 °C. It was experimentally proved that on these catalysts, carbon becomes not only a support but also a reactant due to the formation of the surface oxygen complexes. The oxidation and dissociation of surface oxides play a significant role in the overall process due to the formation of the new active centres. It is experimentally proved that –NCO formation is a major step in the overall mechanism at the low temperature range.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The harmful impact of nitrous oxide derives from its contribution to the greenhouse effect: firstly, N2O has a long lifetime of about 130 years in the atmosphere; secondly, it has two orders of magnitude higher greenhouse potential with respect to that of carbon dioxide due to its ability to absorb infrared radiation from the earth. The low reactivity of N2O is the reason why the gas is stable enough to rise through the troposphere, where it decomposes to nitric oxide which causes the depletion of the ozone layer. Its emission is thought to be mainly from the anthropogenic sources. These include the nitric and adipic acid production, as well as the fossil fuel and biomass combustion [1–5].

As an “end of pipe” solution, the thermal decomposition of N2O requires the temperatures above 700 °C. The alternative is to carry out a catalytic process in which the temperature is considerably lowered. In this sense, the heterogeneous catalytic decomposition seems to be the promising option for the N2O removal [6].

Several studies have examined the mechanism of the N2O decomposition. [5, 7–9]. Generally, there is the agreement in the literature that N2O decomposes on the active metallic sites to N2 and O-adatoms. The latter is very effectively removed from the active sites by the supported carbonaceous materials [10].

The carbon materials represent the unique family of supports because of the diverse nature of the different forms of carbon and the complex functions they can perform. From the sp 2 hybridized chemical bonding in the orderly structure of graphitized carbons and disordered turbostratic carbons like activated carbon, to the sp 3 hybridized configuration in diamond, the different allotropic forms of elemental carbon possess distinct bulk and surface properties which can be altered to modify their characteristics. The use of these different forms of carbons as a heterogeneous catalyst support has grown in the last decades, with activated carbon perhaps being the most studied catalyst support because of the versatility of its properties like: the porosity, surface area and chemical nature, in addition to the mechanical resistance, stability, and inertness.

For the first time, the FTIR studies of the N2O decomposition using carbon films and carbon film supported catalysts are reported. An in situ investigation of these materials was undertaken with the intent of monitoring the entire process by transmission IR, including the catalyst pretreatment, the transient changes during the N2O introduction, and steady-state N2O decomposition. It was expected to learn as much as possible about the state of the catalysts as well as the presence of any surface species. This behaviour was compared with that of the unloaded material in an attempt to clarify the roles of the metal and the support in this reaction on these very active carbonaceous catalysts.

2 Experimental

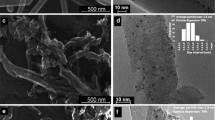

The carbon films used in this study were prepared from cellulose. The charring experiments were detailed elsewhere [11–13]. The cellulose films carbonized at 300 °C in air for 1 h were evacuated at 600 °C for 1 h under the dynamic vacuum (0.13 Pa)—the samples denoted Cdes, worth to note that such material is in the reduced form. The metal-loaded carbon samples denoted CdesMe (Me = Cu, Pt) were prepared by the impregnation procedure using 0.5 M Cu(NO3)2 aqueous solutions as a precursor, and the 3 % solution of H2PtCl6. The metal loading level was set at 1 wt%. The full structural characteristics of the tested catalyst have been described previously [14, 15]. Briefly, based on the results of low-temperature nitrogen adsorption all tested carbon films can be regarded as microporous solids. These materials have a bimodal pore size distribution. The pores are grouped around two main diameters. The first diameter approaches 0.5–0.6 nm (93 % for Cdes sample), while the second diameter occurs in the range of 1.3–1.5 nm. The metal loading in as small amount as 1 wt% practically does not change the structure. Thus, the studied carbon films possess nearly homogeneous microporosity and could be treated as molecular sieve with SBET ca. 480 m2/g.

The activity measurements were made at the atmospheric pressure. The catalytic tests were carried out in the 4 mm ID, quartz, down-flow reactor using 50 mg of the catalyst, which was pretreated for 1 h at 600 °C and cooled to 25 °C in Ar. The procedure guarantee the reduced form of tested materials. Then the catalysts were heated to the reaction temperature in the mixture of reagent gases (600 ppm N2O in Ar). Two experiments were performed. In the first one, before the data were obtained, the process had been maintained for a period of 30 min at the desired temperature (200–600 °C). In the second one, to ensure the steady state conditions, the process was kept at the same temperatures for at least 3 h.

3 Results and Discussion

The nitrous oxide reduction was studied in the temperature range from 200 to 600 °C. The results after 30 min period at each particular temperature are shown in Fig. 1. It was found that under the conditions of 50 ml/min of the total gas stream the outgassed carbon film (Cdes) was practically inactive when the temperature increased from 200 to 350 °C. Above this temperature the percent of decomposition was increasing continuously and reached 80 % at 600 °C. The higher activity was observed in the case of the Cu-loaded sample. The N2O conversion at 600 °C was close to 100 %. The results obtained for the Pt loaded sample show significant differences in a heat and cool cycle. It is clear that a large hysteresis in the consumption of N2O over the Pt-loaded sample exists. The catalyst is more active on the heating branch than on the cooling branch. The increase in the reaction temperature from 300 to 375 °C causes the increase in the N2O conversion from 1 to 55 %. The slight decrease in the activity to 44 % was observed in the temperature range 375–500 °C. The further increase in the reaction temperature causes the increase in the activity i.e. the 97 % conversion at 600 °C. On the cooling branch the N2O conversion starts to drop and it is only slightly higher at the adequate temperatures up to 500 °C. The further decrease in the temperature causes the further decrease in the catalytic activity, i.e. the conversion drops to 6 and 4 % at 400 and 350 °C respectively, being almost equal to the activity of the Cdes sample at this temperature range.

As shown in the right panel in Fig. 1, the production of CO and CO2 during the process occurs. It is worth noting that while the samples had been heat treated in situ under Ar at 600 °C before the reaction, thus, all the decomposed oxygen complexes must have been formed throughout the process.

During the reaction on the Cdes sample the concentration of both carbon oxides was increasing continuously, parallelly to the N2O decomposition and the CO2/CO ratio was lower than the unity in the whole tested temperature range. For Cu loaded carbon the CO2/CO ratio was ca 1 until the temperature of the reaction reached 500 °C. In the case of Pt loaded samples CO2 was the main product in the temperatures below 550 °C. Here the large hysteresis in the CO2 concentration was also observed. It is very interesting to note that the CO2-removal profile is exactly parallel to the decomposition profile at the temperatures below 500 °C. This suggests that certain surface oxygen species, formed during the reaction, should have played very important role in the overall mechanism.

Figure 2 presents the temperature dependence of the N2O decomposition as well as CO2 and CO concentration profiles under the steady state conditions. It is clear that the increase in the catalytic activity of the CdesPt sample at the low temperature range (below 500 °C) is caused by a different mechanism.

In order to explain the observed phenomena in situ studies have been performed. Figure 3 displays the differential IR spectra of the Cdes sample (the background was the spectrum of the sample prior to the reaction). The net changes were caused by the exposition of N2O—the appearance of the bands at 2,217 cm−1 (ν3, asymmetric N–N stretching) and 1,275 cm−1 (ν1, pseudosymmetric N–O stretch). The slight red-shift of those bands with respect to the gas phase spectrum shows that N2O was physically adsorbed on the surface of carbon. The appearance of the small bands at ca 1,600 and 1,720 cm−1 after the 30-min reaction at 200 °C (spectrum A) proved that the surface of carbon was slightly oxidized. While the former band was discussed in the literature [11, 15], the presence of the latter band results directly from the presence of the surface oxygen complexes C(O). The rise in the reaction temperature caused the rise in the intensity of both signals. The red-shift of the signal at 1,600 cm−1 and the appearance of the overlapped bands in the range 1,400–1,100 cm−1 was probably caused as a result of the oxygen atoms having been built into the carbon structures.

The carbon free sites (Cf) have been previously suggested as the active centres during the dissociative adsorption of N2O [16–19] and the reaction occurs due to the formation of carbon–oxygen complexes:

N2O itself can react further with the oxygen complexes removing them as CO2 and creating new free sites:

The formation of the stable oxygen compounds on the surface of a catalyst could explain the fact that at a low temperature range mainly N2 was found as a product [10, 19]. At the higher temperature range, the desorption of C(O) becomes important, giving the increase in the concentration of CO in the effluent gases:

On the other hand, N2O is a soft Lewis base with a canonical structure \(^{ - } {\text{N = N}}^{ + } {\text{ = O}}^{ - }\) and is known to be bonded to the metal active sites through its terminal atoms. The bonding is weak and thought to be due to the donation of electron density from N2O’s higher occupied orbital, with a little backdonation from the metal:

A carbon support could react here as an oxygen scavenger, bringing out the regeneration of the active sites:

The suggested mechanism explains the lack of existence of hysteresis observed for the metal free and Cu loaded carbon sample and the relatively high concentration of CO in the effluent gases. However, in the case of the CdesPt sample, especially at the temperatures below 500 °C, certain additional effects occur. Figure 4 shows the comparison of 2,300–2,000 cm−1 region of the reaction performed on the Pt and Cu loaded samples. Note that the spectra were recorded after cooling down to room temperature and then outgassing, carried out in order to get rid of the bands of physically adsorbed N2O.

Some infrared bands appear in the spectra of the CdesPt sample after the reaction at 300 °C—spectrum (B). These, presented as the band at 2,093 cm−1, attributed to strongly adsorbed CO molecules on Pt sites, which overlapped the band at 2,112 cm−1. The bands, according to the literature, can be assigned to the linearly chemisorbed CO (2,095 cm−1) and multicarbonyl species (2,112 cm−1) [20]. The wavenumber of both bands decrease with the increasing temperature of the reaction by about 7 cm−1 (at 500 °C). Also, the intensities of these bands increase with the rise in temperature of the process. Interestingly, the rise in reaction temperature to 350 °C causes appearance of the band at 2,252 cm−1. This is attributed to the surface –NCO species. Its intensity, i.e. the surface concentration, increases after the reaction at 400 °C. However, the further rise in the temperature causes the decrease in the intensity.

Such effects are not observed on the Cu loaded sample, where the only one band is present in this spectral region. This band is attributed to the multicarbonyl species, at 2,112 cm−1 [right panel spectra (B)–(F)]. Its intensity increases progressively with the rise in the temperature from 300 to 500 °C. A very weak band at 2,221 cm−1 was assigned to residual N2O, adsorbed in the pore structures. It has been suggested in the literature [17] that the existence of the active metal phase may result in the lability of the surface oxygen formed during the N2O dissociative chemisorption. This, in turn, could affect the oxygen transfer from the active phase to the support. The presence of the more labile oxygen results in the easier transfer and faster formation of the surface C(O) and CO in the effluent.

However, the results presented above lead to the reconsideration of the proposed mechanism. It is necessary to incorporate the surface –NCO, as the intermediate and CO2 as the main product. Thus, over the Pt loaded sample, beside the \({\text{Pt}} \cdots {\text{O}}\) surface species the \({\text{Pt}} \cdots {\text{N}}\) functionalities should also form as the product of the reaction:

Due to the fact that NO was observed neither in the gas phase nor on the surface of the catalyst both conclusions are possible: (i) the reaction (8) is reversible (according to the literature data N2O is the product during NOx decomposition [15, 21]) or (ii) NO lifetime is shortened because of the reaction with chemisorbed CO:

The proposed mechanism also explains the diminishing of the catalytic activity of CdesPt, while being cooled down (see Fig. 1), which is caused by covering the Pt sites by the CO molecules. The strong CO chemisorption disables the formation of \({\text{Pt}} \cdots {\text{N}}\) whose presence is crucial in the low temperature range. Note that the reactions (9)–(11) were proposed recently to explain the mechanism of the NO reduction by CO over the Ba-based Pt catalysts [22].

4 Conclusions

In this work, the decomposition of N2O was examined to investigate the activity of carbon and carbon-supported materials with the purpose of understanding the reaction mechanism. It was experimentally confirmed that the carbonaceous materials play a double role in the tested reaction, both as an adsorbent and reactant, due to the formation of the surface oxygen complexes C(O). The decomposition of the latter to CO and/or CO2 is probably of decisive importance in the overall process owing to the formation of the new active centres at the high temperature range. However, the additional effects appear on the Pt loaded carbon films, especially at the lower temperatures. The most important surface species is surface –NCO which determines formation of CO2 as the main product of the process.

References

Kapteijn F, Rodriguez-Mirasol J, Moulijn JA (1996) Appl Catal B 9:25

Armor JN (1992) Appl Catal B 1:221

Li Y, Armor JN (1993) Appl Catal B 3:55

Goncalves F, Figueiredo JL (2004) Appl Catal B 50:271

Dandekar A, Vannice MA (1999) Appl Catal B 22:179

Pérez-Ramirez J, Kapteijn F, Mul G, Moulijn JA (2002) Appl Catal B 35:227

Chellam U, Xu ZP, Zeng HC (2000) Chem Mater 12:650

Rivallan M, Ricchiardi G, Bordiga S, Zecchina A (2009) J Catal 264:104

Pinna F, Scarpa M, Strukul G, Guglielminotti E, Boccuzzi F, Mandoli M (2000) J Catal 192:158

Carabineiro SA, Bras Fernandes F, Vital JS, Ramos AM, Fonseca IM (2005) Appl Catal B 59:181

Zawadzki J (1989) In: Thrower PA (ed) Chemistry and physics of carbon, vol 21. Dekker, New York, pp 147–380

Zawadzki J, Wiśniewski M (2007) Catal Today 119:213

Zawadzki J, Wiśniewski M, Skowrońska K (2002) Appl Catal B 35:255

Terzyk AP, Gauden PA, Zawadzki J, Rychlicki G, Wiśniewski M, Kowalczyk P (2001) J Coll Inter Sci 243:183

Zawadzki J, Wiśniewski M (2002) Carbon 40:119

Li YH, Lu GQ, Rudolph V (1998) Chem Eng Sci 53:1

Grzybek T, Klinik J, Dutka B, Papp H, Supron V (2005) Catal Today 101:93

Zhu ZH, Wang S, Lu GQ, Zhang DK (1999) Catal Today 53:669

Rodrigues-Mirasol J, Ooms AC, Pels JR, Kapteijn F, Moulijn JA (1994) Combust Flame 99:499

Benvenutti EV, Franken L, Moro CC (1999) Langmuir 15:8140

Zawadzki J, Wiśniewski M, Skowrońska K (2003) Carbon 41:235

Ji Y, Toops TJ, Crocker M (2013) Appl Catal B 140–141:265

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Wiśniewski, M. Mechanistic Aspects of N2O Decomposition Over Carbon Films and Carbon-Film-Supported Catalysts. Catal Lett 144, 633–638 (2014). https://doi.org/10.1007/s10562-013-1180-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-013-1180-6