Abstract

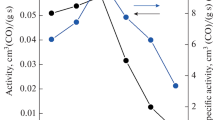

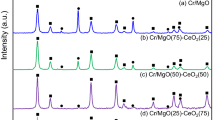

The crystallographic structure of (11 wt.%)CuO–(6 wt.%)CeO2/γ-Al2O3 has been studied and compared with (11 wt.%)CuO/γ-Al2O3 under reducing conditions, using time-resolved in situ X-ray diffraction in the temperature range 25–800 °C. In CuO–CeO2/Al2O3, H2-TPR reduces the CuO phase to Cu, while in C3H8-TPR reduction follows a two-step pathway via Cu2O. A thermal treatment in He also induces reduction for CuO, albeit at higher temperature. In addition to CuO reduction, the CeO2 promoter in CuO–CeO2/Al2O3 is also partially reduced, without crystallographic transition, regardless of the atmosphere and at similar temperature where reduction of CuO occurs. Supported CuO as in CuO–CeO2/Al2O3 or CuO/Al2O3, is more readily reduced by thermal treatment in He than unsupported CuO and Cu2O. Moreover, the addition of CeO2 to the CuO–CeO2/Al2O3 catalyst allows for enhanced reducibility of CuO, compared to CuO/Al2O3. The CuO phase in CuO–CeO2/Al2O3 is reduced to Cu2O and partly to Cu at 700 °C and mainly to Cu at 800 °C in He flow. The thermal reduction of CuO–CeO2/Al2O3 requires an apparent activation energy of 216 kJ/mol.

Graphical Abstract

An isothermal reduction treatment at 800 oC in He reduces CuO–CeO2/Al2O3, as demonstrated by time-resolved in situ X-ray diffraction. Supported CuO are more easily reduced by thermal treatment compared to unsupported CuO and Cu2O. The CuO phase in CuO–CeO2/Al2O3 is reduced to Cu2O and partly to Cu at 700 °C and mainly to Cu at 800 °C in He flow (see figure)

Similar content being viewed by others

References

Armor JN (1992) Appl Catal B 1:221–256

Everaert K, Baeyens J (2004) J Hazard Mater 109:113–139

Christopher JGI, Heyes J, Hilary J, Moss JARL (1982) J Chem Technol Biotechnol 32:1025–1033

Larsson P-O, Andersson A (1998) J Catal 179:72–89

Wang C-H, Lin S-S, Chen C-L, Weng H-S (2006) Chemosphere 64:503–509

Heynderickx PM, Thybaut JW, Poelman H, Poelman D, Marin GB (2010) J Catal 272:109–120

Alexopoulos K, Anilkumar M, Reyniers M-F, Poelman H, Cristol S, Balcaen V, Heynderickx PM, Poelman D, Marin GB (2010) Appl Catal B 97:381–388

Huang T-J, Tsai D-H (2003) Catal Lett 87:173–178

Doornkamp C, Ponec V (2000) J Mol Catal A 162:19–32

Grzybowska-Świerkosz B (2000) Top Catal 11–12:23–42

Busca G, Daturi M, Finocchio E, Lorenzelli V, Ramis G, Willey RJ (1997) Catal Today 33:239–249

Balcaen V, Roelant R, Poelman H, Poelman D, Marin GB (2010) Catal Today 157:49–54

Rubio O, Herguido J, Menéndez M (2003) Chem Eng Sci 58:4619–4627

Haber J, Turek W (2000) J Catal 190:320–326

Liu D-J, Robota HJ (1993) Catal Lett 21:291–301

Amano F, Tanaka T, Funabiki T (2004) J Mol Catal A 221:89–95

Iwamoto M, Yahiro H, Tanda K, Mizuno N, Mine Y, Kagawa S (1991) J Phys Chem 95:3727–3730

Llabres i Xamena FX, Fisicaro P, Berlier G, Zecchina A, Palomino GT, Prestipino C, Bordiga S, Giamello E, Lamberti C (2003) J Phys Chem. B 107: 7036–7044

Menon U, Galvita VV, Marin GB J Catal. 283:1–9

Wang X, Hanson JC, Frenkel AI, Kim J-Y, Rodriguez JA (2004) J Phys Chem B 108:13667–13673

Kim JY, Rodriguez JA, Hanson JC, Frenkel AI, Lee PL (2003) J Am Chem Soc 125:10684–10692

Kim JY, Hanson JC, Frenkel AI, Lee PL, Rodriguez JA (2004) J Phys Condens Matter 16:S3479–S3484

Yamaguchi A, Shido T, Inada Y, Kogure T, Asakura K, Nomura M, Iwasawa Y (2001) Bull Chem Soc Jpn 74:801–808

Reitz TL, Lee PL, Czaplewski KF, Lang JC, Popp KE, Kung HH (2001) J Catal 199:193–201

Oguchi H, Kanai H, Utani K, Matsumura Y, Imamura S (2005) Appl Cat A 293:64–70

Smith ML, Campos A, Spivey JJ (2012) Catal Today 182:60–66

Silversmit G, Poelman H, Balcaen V, Heynderickx PM, Olea M, Nikitenko S, Bras W, Smet PF, Poelman D, De Gryse R, Reniers MFO, Marin GB (2009) J Phys Chem Solids 70:1274–1284

Aneggi E, Boaro M, de Leitenburg C, Dolcetti G, Trovarelli A (2006) J Alloys Compd 408–412:1096–1102

Martinez-Arias A, Gamarra D, Fernandez-Garcia M, Wang XQ, Hanson JC, Rodriguez JA (2006) J Catal 240:1–7

Cao Y, Casenas B, Pan W-P (2006) Energy Fuels 20:1845–1854

Malinin GV, Tolmachev YM (1975) Russ Chem Rev 44:392

Kirsch PD, Ekerdt JG (2001) J Appl Phys 90:4256

Bera P, Aruna ST, Patil KC, Hegde MS (1999) J Catal 186:36–44

Shapovalov V, Metiu H (2007) J Catal 245:205–214

Acknowledgments

This work was supported by the ‘Long Term Structural Methusalem Funding by the Flemish Government’.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Galvita, V.V., Poelman, H., Rampelberg, G. et al. Structural and Kinetic Study of the Reduction of CuO–CeO2/Al2O3 by Time-Resolved X-ray Diffraction. Catal Lett 142, 959–968 (2012). https://doi.org/10.1007/s10562-012-0859-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-012-0859-4