Abstract

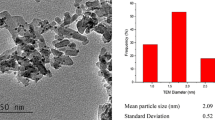

Monodisperse Pt nanoparticles (NPs) with well-controlled sizes in the range between 1.5 and 10.8 nm, and shapes of octahedron, cube, truncated octahedron and spheres (~6 nm) were synthesized employing the polyol reduction strategy with polyvinylpyrrolidone (PVP) as the capping agent. We characterized the as-synthesized Pt nanoparticles using transmission electron microscopy (TEM), high resolution TEM, sum frequency generation vibrational spectroscopy (SFGVS) using ethylene/H2 reaction as the surface probe, and the catalytic ethylene/H2 reaction by means of measuring surface concentration of Pt. The nanoparticles were supported in mesoporous silica (SBA-15 or MCF-17), and their catalytic reactivity was evaluated for the methylcyclopentane (MCP)/H2 ring opening/ring enlargement reaction using 10 torr MCP and 50 torr H2 at temperatures between 160 and 300 °C. We found a strong correlation between the particle shape and the catalytic activity and product distribution for the MCP/H2 reaction on Pt. At temperatures below 240 °C, 6.3 nm Pt octahedra yielded hexane, 6.2 nm Pt truncated octahedra and 5.2 nm Pt spheres produced 2-methylpentane. In contrast, 6.8 nm Pt cubes led to the formation of cracking products (i.e. C1–C5) under similar conditions. We also detected a weak size dependence of the catalytic activity and selectivity for the MCP/H2 reaction on Pt. 1.5 nm Pt particles produced 2-methylpentane for the whole temperature range studied and the larger Pt NPs produced mainly benzene at temperatures above 240 °C.

Graphical abstract

Similar content being viewed by others

References

Zaera F, Godbey D, Somorjai GA (1986) J Catal 101:73–80

Narayanan R, El-Sayed MA (2004) Nano Lett 4:1343–1348

Kuhn JN, Tsung CK, Huang W, Somorjai GA (2009) J Catal 265:209–215

Tsung CK, Kuhn JN, Huang WY, Aliaga C, Hung LI, Somorjai GA, Yang PD (2009) J Am Chem Soc 131:5816–5822

Kuhn JN, Huang WY, Tsung CK, Zhang YW, Somorjai GA (2008) J Am Chem Soc 130:14026

Kliewer CJ, Aliaga C, Bieri M, Huang WY, Tsung CK, Wood JB, Komvopoulos K, Somorjai GA (2010) J Am Chem Soc 132:13088–13095

Brandenberger SG, Callender WL, Meerbott WK (1976) J Catal 42:282–287

Zhuang YP, Frennet A (1999) Appl Catal A Gen 177:205–217

Galperin LB, Bricker JC, Holmgren JR (2003) Appl Catal A Gen 239:297–304

Bai XL, Sachtler WMH (1991) J Catal 129:121–129

Teschner D, Paal Z, Duprez D (2001) Catal Today 65:185–190

Samoila P, Boutzeloit M, Especel C, Epron F, Marecot P (2009) Appl Catal A Gen 369:104–112

Poupin C, Pirault-Roy L, La Fontaine C, Toth L, Chamam M, Wootsch A, Paal Z (2010) J Catal 272:315–319

Vaarkamp M, Dijkstra P, Vangrondelle J, Miller JT, Modica FS, Koningsberger DC, Vansanten RA (1995) J Catal 151:330–337

Kramer R, Fischbacher M (1989) J Mol Catal 51:247–259

Anderson JBF, Burch R, Cairns JA (1987) J Catal 107:351–363

Glassl H, Hayek K, Kramer R (1981) J Catal 68:397–405

Rioux RM, Song HJ, Yang PD, Somorjai GA (2005) Abstr Pap Am Chem S 229:U723–U723

Fievet F, Lagier JP, Blin B, Beaudoin B, Figlarz M (1989) Solid State Ionics 32–3:198–205

Alayoglu S, Eichhorn B (2008) J Am Chem Soc 130:17479–17486

Horiuti I, Polanyi M (1934) T Faraday Soc 30:1164–1172

Cremer PS, Su XC, Shen YR, Somorjai GA (1996) J Am Chem Soc 118:2942–2949

McCrea KR, Somorjai GA (2000) J Mol Catal A Chem 163:43–53

Watwe RM, Cortright RD, Norskov JK, Dumesic JA (2000) J Phys Chem B 104:2299–2310

Anghel AT, Jenkins SJ, Wales DJ, King DA (2006) J Phys Chem B 110:4147–4156

Sun YG, Xia YN (2002) Science 298:2176–2179

Hayek K, Kramer R, Paal Z (1997) Appl Catal A Gen 162:1–15

Hayek K, Fuchs M, Klotzer B, Reichl W, Rupprechter G (2000) Top Catal 13:55–66

Corolleu C, Juttard D, Muller JM, Gault FG, Maire G (1972) J Catal 27:466

Alvarez WE, Resasco DE (1996) J Catal 164:467–476

Rioux RM, Hsu BB, Grass ME, Song H, Somorjai GA (2008) Catal Lett 126:10–19

Rupprechter G, Freund HJ (2001) Top Catal 14:3–14

Acknowledgments

This work is funded by Office of Science, Department of Energy. The authors acknowledge support of the National Center for Electron Microscopy, Lawrence Berkeley Lab, which is supported by the U.S. Department of Energy under Contract # DE-AC02-05CH11231. Work at the Molecular Foundry was supported by the Director, Office of Science, Office of Basic Energy Sciences, Division of Material Sciences and Engineering, of the U.S. Department of Energy under Contract # DE-AC02-05CH11231.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Alayoglu, S., Aliaga, C., Sprung, C. et al. Size and Shape Dependence on Pt Nanoparticles for the Methylcyclopentane/Hydrogen Ring Opening/Ring Enlargement Reaction. Catal Lett 141, 914–924 (2011). https://doi.org/10.1007/s10562-011-0647-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-011-0647-6