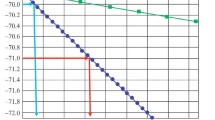

Research results of impurity water accumulation and removal processes in cryogenic separation units for high-purity inert gas production (with a purity of more than 99.999 %) are presented. Dewpoint temperature calculations for gases at various pressures are made. Main sources of moisture contamination in the product gaseous flows of cryogenic separation units are determined. Recommendations regarding both the pre-purification technology for cryogenic separation unit feed gas and the cylinder filling process are provided, which make it possible to reduce water vapor concentration in gas to the level of ppb (parts per billion, 1 ppb = 10–9 mol/mol).

Similar content being viewed by others

References

V. L. Bondarenko, M. Yu. Kupriyanov, T. G. Ustyugova, et al., “Gas chromatography in technology of high-purity Noble gases,” Chem. Petrol. Eng., 56, No. 1–2, 1–8 (2019).

V. L. Bondarenko, Yu. M. Simonenko, and A. A. Chigrin, “Automated cryogenic unit for xenon extraction from concentrated mixtures,” Chem. Petrol. Eng., 54, No. 9–10, 651–657 (2019).

V. L. Bondarenko, A. N. Kislyi, and O. V. Dyachenko, “Production of high-purity krypton and xenon. Purification from trace impurities,” Chem. Petrol. Eng., 52, No. 9–10, 693–700 (2017).

V. L. Bondarenko, E. G. Korzh, T. V. Dyachenko, and O. V. Dyachenko, “Estimation of the cost of producing and enriching a krypton-xenon mixture,” Chem. Petrol. Eng., 51, No. 1-2, 67–73 (2015).

V. Bondarenko, I. Arkharov, A. Bondarenko, M. Poddubna, and I. Symonenko, “Optimization of adsorbers used in purification technologies of rare gases,” Proceeding of the 24th IIR International Congress of Refrigeration, ICR 2015, Yokohama, Japan, 232–238 (2015).

V. L. Bondarenko, Y. M. Simonenko, and A. A. Chigrin, “Optimization of design and operational parameters of adsorbers for purification of Neon-Helium mixture,” Chem. Petrol. Eng., 51, No. 9–10, 683–690 (2016).

F. de Azevedo Medeiros, F. M. Shiguematsu, F. B. Campos, et al., “Alternative EoSbased model for predicting water content, metastable phase and hydrate formation in natural gas systems,” J. Nat. Gas Sci. Eng., 36, Part A, 550–562 (2016).

J. Wu and F. Shadman, “Impurity drift and variations in high purity gas delivery systems,” International Journal of Engineering and Mathematical Modelling, 1–9 (2018).

H. Abe and K. M. T. Yamada, “Performance evaluation of a trace-moisture analyzer based on cavity ring-down spectroscopy: Direct comparison with the NMIJ trace-moisture standard,” Sensors and Actuators A, 165, No. 2, 230–238 (2011).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, Vol. 56, No. 5, pp. 23–26, May, 2020.

Rights and permissions

About this article

Cite this article

Ustyugova, T.G., Kupriyanov, M.Y. Moisture Contamination in High Purity Gas Separation Products. Chem Petrol Eng 56, 371–377 (2020). https://doi.org/10.1007/s10556-020-00783-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-020-00783-y