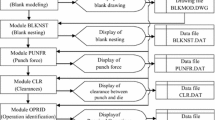

In this paper, mathematical modeling of objects layout is considered for the phase of construction engineering of industrial facilities. The authors propose a new approach that allows to define the problem and to automatically create a mathematical layout model of the industrial facilities. The approach is based on a method of generating and controlling the limitations of the mathematical layout model. The distinctive feature of this method is the possibility to add new restrictions and to consider them in the process of layout calculations without changing the code. The proposed approach has been tested in solving practical problems of designing layouts of industrial facilities.

Similar content being viewed by others

References

V. V. Kafarov and V. N. Vetokhin, Fundamentals of Computer-Aided Design in Chemical Industry, I. M. Makarov (ed.), Nauka, Moscow (1987).

V. V. Kafarov, V. P. Meshalkin, and B. B. Bogomolov, “Mathematical formulation of the problem of optimal arrangement of equipment in a workshop,” Khim. Prom., No. 1, 51–54 (1980).

S. Ya. Egorov, “Methodology of automated search for space-planning solutions in the chemical industry,” Khim. Prom., No. 10, 35–55 (2006).

T. C. Koopmans and M. Beckmann, “Assignment problems and the location of economic activities,” Econometrica, 25, No. 1, 53–76 (1957).

R. D. Meller, V. Narayanan, and P. H. Vance, “Optimal facility layout design,” Oper. Res. Lett., 23, Nos. 3–5, 117–127 (1999).

Y. H. Lee and M. H. Lee, “A shape-based block layout approach to facility layout problems using hybrid genetic algorithm,” Comput. Ind. Eng., No. 42, 237–248 (2002).

T. Yang, B. A. Peters, and M. Tu, “Layout design for flexible manufacturing systems, considering single-loop directional flow patterns,” Eur. J. Oper. Res., 164, No. 2, 440–455 (2005).

K. A. Sharonin, The Algorithm and Software Complex for Constructing a Mathematical Model of the Layout of Industrial Objects: Dissert. Cand. Techn. Sci., Tambov (2014).

V. G. Mokrozub, K. A. Sharonin, and K. V. Nemtinov, “Software for automated layout of objects in a space invariant to a subject domain,” Nauch.-Tekhn. Inform., Ser. 2, Inform. Prots. Syst., No. 3, 11–29 (2012).

V. G. Mokrozub, A. N. Polyakov, and A. I. Serdyuk, “Automated information system for the preparation of production of machine-building enterprises,” Vestn. Tamb. Gos. Tekhn. Univ., 18, No. 3, 598–603 (2012).

E. N. Malygin, S. Ya. Egorov, and K. A. Sharonin, “Algorithm for the automated development of a mathematical model for the arrangement of industrial objects,” Nauch.-Tekhn. Inform., Ser. 2, Inform. Prots. Syst., No. 2, 7–15 (2015).

S. Ya. Egorov and K. A. Sharonin, Cert. Registr. Comp. Progr. No. 2014613415, “System for formulation and control of restrictions in tasks of assembling technological complexes,” March 26, 2014.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, No. 6, pp. 31–34, June, 2017.

Rights and permissions

About this article

Cite this article

Egorov, S.Y., Sharonin, K.A. Automated Decision Making in the Problem Solving of Objects Layout for Chemical and Refining Industries Using Expert Software Systems. Chem Petrol Eng 53, 396–401 (2017). https://doi.org/10.1007/s10556-017-0353-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-017-0353-3