Abstract

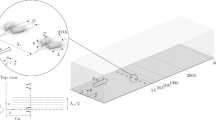

In aero-engines, mutiperforation cooling systems are often used to shield the combustor wall and ensure durability of the engine. Fresh air coming from the casing goes through thousands of angled perforations and forms a film which protects the liner. When performing Large Eddy Simulations (LES) of a real engine, the number of sub-millimetric holes is far too large to allow a complete and accurate description of each aperture. Homogeneous models allow to simulate multiperforated plates with a mesh size bigger than the hole but fail in representing the jet penetration and mixing. A heterogeneous approach is proposed in this study, where the apertures are thickened if necessary so that the jet-crossflow interaction is properly represented. Simulations using homogeneous and thickened-hole models are compared to a fully resolved computation for various grid resolutions in order to illustrate the potential of the method.

Similar content being viewed by others

References

Schulz, A.: Combustor liner cooling technology in scope of reduced pollutant formation and rising thermal efficiencies. Ann. N. Y. Acad. Sci. 934(1), 135–146 (2001)

Rizk, N., Mongia, H.: Low NOx rich-lean combustion concept application. AIAA paper (91-1962) (1991)

Goldstein, R.J.: Film cooling. Adv. Heat Tran. 7, 321–379 (1971)

Lefebvre, A.H.: Gas Turbines Combustion. Taylor & Francis, New York (1999)

Poprawe, R., Kelbassa, I., Walther, K., Witty, M., Bohn, D., Krewinkel, R.: Optimising and manufacturing a laser-drilled cooling hole geometry for effusion-cooled multi-layer plates. Proc. of ISROMAC-12, Paper (20091) (2008)

Mayle, R.E., Camarata, F.J.: Multihole cooling effectiveness and heat transfer. J. Heat Transf. 97, 534–538 (1975)

Pietrzyk, J.R., Bogard, D.G., Crawford, M.E.: Hydrodynamic measurements of jets in crossflow for gas turbine film cooling applications. J. Turbomach. 111, 139–145 (1989)

Sinha, A.K., Bogard, D.G., Crawford, M.E.: Film-cooling effectiveness downstream of a single row of holes with variable density ratio. J. Turbomach. 113, 442–449 (1991)

Crawford, M.E., Kays, W.M., Moffat, R.J.: Full-coverage film cooling. part I: comparison of heat transfer data for three injection angles. J. Eng. Gas Turbines Power 102, 1000–1005 (1980)

Hale, C.A., Plesniak, M.W., Ramadhyani, S.: Film cooling effectiveness for short film cooling holes fed by a narrow plenum. J. Turbomach. 122, 553–557 (2000)

LeBrocq, P.V., Launder, B.E., Priddin, C.H.: Discrete hole injection as a means of transpiration cooling; an experimental study. Proc. Inst. Mech. Eng. 187(17), 149–157 (1973)

Metzger, D.E., Takeuchi, D.I., Kuenstler, P.A.: Effectiveness and heat transfer with full-coverage film-cooling. ASME Paper 73-GT-18 (1973)

Briones, A.M., Rankin, B.A., Stouffer, S.D., Erdmann, T.J., Burrus, D.L.: Parallelized, automated, and predictive imprint cooling model for combustion systems. J. Eng. Gas Turbines Power 139(3), 031505 (2017)

Burdet, A., Abhari, R.S., Rose, M.G.: Modeling of film cooling—Part II model for use in three-dimensional computational fluid dynamics. J. Turbomach. 129 (2), 221–231 (2007)

Mazzei, L., Mazzei, L., Andreini, A., Andreini, A., Facchini, B., Facchini, B.: Assessment of modelling strategies for film cooling. Int. J. Numer. Methods Heat Fluid Flow 27(5), 1118–1127 (2017)

Mendez, S., Nicoud, F.: Adiabatic homogeneous model for flow around a multiperforated plate. AIAA J. 46(10), 2623–2633 (2008)

Rida, S., Reynolds, R., Chakracorty, S., Gupta, K.: Imprinted effusion modeling and dynamic cd calculation in gas turbine combustors. ASME Paper No GT2012-68804 (2012)

Voigt, S., Noll, B., Aigner, M.: Development of a macroscopic CFD model for effusion cooling applications. ASME Paper No GT2012-68251 (2012)

Mendez, S., Nicoud, F.: Large-eddy simulation of a bi-periodic turbulent flow with effusion. J. Fluid Mech. 598, 27–65 (2008)

Most, A., Savary, N., Bérat, C.: Reactive flow modelling of a combustion chamber with a multiperforated liner. AIAA Paper (2007–5003) (2007)

Lahbib, D.: Modélisation Aérodynamique et Thermique des Multiperforations en LES. PhD thesis, Université Montpellier II (2015)

Koupper, C., Gicquel, L., Duchaine, F., Bonneau, G.: Advanced combustor exit plane temperature diagnostics based on large eddy simulations. Flow Turbul. Combust. 95(1), 79–96 (2015)

Jaegle, F., Cabrit, O., Mendez, S., Poinsot, T.: Implementation methods of wall functions in cell-vertex numerical solvers. Flow Turbul. Combust. 85(2), 245–272 (2010)

Miron, P.: Étude Expérimentale des Lois de Parois et du Film de Refroidissement Produit par une Zone Multiperforée sur une Paroi Plane. Phd thesis, Université de Pau et des Pays de l’Adour (2005)

Florenciano, J.-L., Bruel, P.: LES fluid–solid coupled calculations for the assessment of heat transfer coefficient correlations over multi-perforated walls. Aerosp. Sci. Technol. 53, 61–73 (2016)

Florenciano, J.: Etude de la Réponse d’un Écoulement Avec Transfert Pariétal de Masse à un Forçage Acoustique. PhD thesis, Université de Pau (2013)

Petre, B., Dorignac, E., Vullierme, J.J.: Study of the influence of the number of holes rows on the convective heat transfer in the case of full coverage film cooling. Int. J. Heat Mass Transf. 46(18), 3477–3496 (2003)

Lamouroux, J., Richard, S., Malé, Q., Staffelbach, G., Dauptain, A., Misdariis, A.: On the combination of large eddy simulation and phenomenological soot modelling to calculate the smoke index from aero-engines over a large range of operating conditions. In: ASME Turbo Expo 2017: Turbomachinery Technical Conference and Exposition, pp. V04BT04A004–V04BT04A004. American Society of Mechanical Engineers (2017)

Thomas, M., Dauptain, A., Gicquel, L., Duchaine, F., Koupper, C., Nicoud, F.: Comparison of heterogeneous and homogeneous coolant injection models for large eddy simulation of multiperforated liners present in a combustion simulator. ASME Paper No GT2017-64622 (2017)

Vignat, G., Taliercio, G., Lamouroux, J., Da Veiga, S., Savary, N., Duchaine, P.: Analysis of performance sensitivity to geometrical variations of a modern helicopter engine combustor using les simulations. In: ASME Turbo Expo 2017: Turbomachinery Technical Conference and Exposition, pp. V04BT04A003–V04BT04A003. American Society of Mechanical Engineers (2017)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bizzari, R., Lahbib, D., Dauptain, A. et al. A Thickened-Hole Model for Large Eddy Simulations over Multiperforated Liners. Flow Turbulence Combust 101, 705–717 (2018). https://doi.org/10.1007/s10494-018-9909-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10494-018-9909-3