Abstract

For the first time, the ripple effect is examined in the setting of an intertwined supply network. Through simulations, we model the disruption propagation in supply chains having common suppliers. We explore conditions under which a collaborative coordination of re-purposed capacities and shared stocks can help mitigate the ripple effect and improve recovery performance. As a result, we conceptualize the notion of collaborative emergency adaptation contributing to development of “network-of networks” and viability perspective in supply chain resilience management. We illustrate our approach with anyLogistix simulations and deduce some generalized theoretical and managerial insights on how and when a collaborative emergency adaptation can be implemented and help improve supply chain resilience and viability.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Disruptions at different echelons in supply chains can be localized without an associated cascading throughout a network, or propagate downstream and cause the ripple effect adversely impacting performance of individual firms and networks ((Ivanov et al., 2014a, b; Dolgui et al., 2018; Kinra et al., 2020; (Li et al., 2020b; Osadchiy et al., 2021; Iftikhar et al., 2022; Llaguno et al., 2022). According to Dolgui et al. (2020a), the ripple effect “refers to structural dynamics and describes a downstream propagation of the downscaling in demand fulfilment in the supply chain as a result of a severe disruption.”

Bullwhip and ripple effects are two types of systemic risks and specific areas of supply chain resilience (Osadchiy et al., 2016; Scheibe & Blackhurst, 2018; Sawik, 2020, Ivanov and Dolgui, 2021, Li et al., 2021a, b; Katsaliaki et al., 2022; Hägele et al., 2023). While literature has mostly focused on the ripple effect in supply chains of particular firms, collaboration of different supply chain networks in the ripple effect settings remained underexplored. In particular, the intertwined supply network (ISN), which is an ‘entirety of interconnected supply chains which, in their integrity secure the provision of society and markets with goods and services’ (Ivanov & Dolgui, 2020) becomes an important concept where ripple effect examination is still missing. Moreover, moving the discussion toward ISNs has resulted in development of a new notion for supply chain disruption management, i.e., the viability, which integrates resilience and sustainability (Ivanov & Dolgui, 2020, Ivanov, 2021a, Sawik, 2023).

Viability is the “ability of a supply chain to maintain itself and survive in a changing environment through a redesign of structures and replanning of performance with long-term impacts” (Ivanov & Dolgui, 2020, Ivanov, 2022b). The viable supply chain model proposed by Ivanov (2022c) is a new approach to conceptualize intertwining of different supply chain designs echoed by Ivanov and Dolgui (2022a; Ivanov et al. (2023)) pointing to the importance of stress-testing the entire ecosystems, and not only firm’s supply chains. Ruel et al. (2021) and Ivanov and Keskin (2023) stress the role of the ripple effect mitigation in building viable supply chains. Li et al. (2022a, b, c, d, e; MacCarthy et al., (2022)) elaborate on importance of supply chain preparedness and mapping pointing to the role of collaboration in adaptive emergency responses.

Managing disruptions in ISNs has several distinct problems and chances as compared to individual supply chains. Difficulties of the ripple effect control in the ISNs are triggered by ISN complexity, higher decentralization degree, and lower observability (Feizabadi et al., 2023). Chances are offered by a broader pool of resources available for adaptation, and structural network variety (Ivanov et al., 2023). Consider an example. During the COVID-19 pandemic, commercial and healthcare supply chains have been intertwined as an emergency response to shortages of medical equipment caused by the ripple effects of propagating disruptions in demand and supply (Choi, 2021). As shown in Ivanov (2021a), Ford’s automotive supply chain intertwined with healthcare supply chains. Ford repurposed their production line to help healthcare sector to cope with a shortage of PPE (personal protection equipment) within two weeks. In collaboration with the hospital managers, face shields designs have been identified that could be built by a re-purposed Ford’s supply chain. Material planning and logistics started planning inbound and outbound deliveries for the newly established product. Suppliers started delivering materials to production sites. On the same day, the first prototype was completed, and an initial prototype production run was established. Next day, new suppliers have been identified to resolve capacity problems with supply for some materials needed for the face shield production. The first 5,000 face shields arrived at the hospitals. Some problems needed to be operatively resolved. The supply of elastic bands was identified as not sufficient for full speed production. Alternative product designs have been validated, and new suppliers have been identified and contacted. Thus, in one week, Ford was able to go from idea to mass production. Other examples include Est´ee Lauder and Bacardi sanitizers and Gucci and Ralph Lauren masks and medical gowns. However, time delays, high coordination efforts, and long shortage periods occurred during these adaptations. For example, three-quarters of sanitizer manufacturers faced severe material shortage, including alcohol and packaging, after using full capacity to ramp up production (Paul & Chowdhury, 2021; Müller et al., 2022) provide empirical evidence of such a networking in companies that adopted ad hoc supply chain re-purposing. They examined adaptation processes with full range of related activities, i.e., to find new suppliers, to develop the products, to ramp-up production, and to distribute to new customers.

This cross-industry networking can be called a “network of networks” adaptation building on the concepts of physical internet (Pan et al., 2017), ISNs (Ivanov & Dolgui, 2020; Feizabadi et al., 2023), and supply chain commons (Chopra et al., 2021). Despite a considerable progress done in the ripple effect and ISN research separately, there is still a lack of understanding the ripple effect mechanisms in the ISNs. We define the following research questions (RQ) for our study:

RQ1: How does the timing of collaborative adaptation deployment impact the ripple effect and supply chain performance?

RQ2: When and how a collaborative coordination of re-purposed capacities and shared stocks in ISNs can help mitigate the ripple effect and improve recovery performance of supply chains?

Our contribution is twofold. First, we contribute to literature by examining the ripple effects in the ISN setting. We model the disruption propagation in supply chains, which are intertwined having common suppliers (contractual manufacturers). Through simulations, we explore the effects of collaborative disruption responses and conditions under which a collaborative allocation of shared/re-purposed capacities and stocks can help mitigate the ripple effect and improve recovery performance of supply chains. Second, we conceptualize the notion of collaborative emergency adaptation contributing to development of “network-of networks” perspective in supply chain resilience management. We illustrate our approach with anyLogistix simulations and deduce some generalized theoretical and managerial insights on how and when a collaborative emergency adaptation can help improve supply chain resilience.

The rest of this paper is organized as follows. Section 2 offers a literature review on the ripple effect, ISNs, and collaborative disruption management. In Sect. 3, the simulation model is described. Experimental results are presented and discussed in Sect. 4. Section 5 is devoted to theoretical and managerial insights. We conclude in Sect. 6 by summarizing major outcomes of this study and outlining some future research topics.

2 Literature review

We build on and contribute to three research streams, i.e., the ripple effect, ISNs, and collaborative disruption response. We organize our literature review accordingly.

2.1 Ripple effect in supply chains

An increased interest in the ripple effect in supply chains has been observed at the beginning of the second decade of the 21st century (Liberatore et al., 2012; Ghadge et al., 2013; Mizgier et al., 2013; Swierczek, 2014; (Ivanov et al., 2014b; Zeng & Xiao, 2014; Garvey et al., 2015). The first definition of the ripple effect was coined by Ivanov et al. (2014a): “Ripple effect describes the impact of a disruption on supply chain performance and disruption-based scope of changes in the supply chain structures and parameters “.

Research on the ripple effect has been considerably grown as documented in literature reviews by Dolgui et al. (2018), Hosseini et al. (2019), Ivanov and Dolgui (2021b), Dolgui and Ivanov (2021), Shi et al. (2022) and Llaguno et al. (2022), as well the handbook of the ripple effect in supply chains ((Ivanov et al., 2019b). Most of the papers published before 2020 have studied propagation of a single disruption through some downstream echelons Han & Shin, 2016; Tang et al., 2016; (Ivanov, 2017, 2019; Levner & Ptuskin, 2018; Deng et al., 2019; Hosseini et al., 2020; Li & Zobel, 2020; Lei et al., 2021; (Hosseini & Ivanov, 2022b, Sindhvani et al., 2022, Yu et al., 2022). This body of literature developed multiple methods for mitigating the ripple effect through backup sourcing, capacity flexibility, and inventory optimization as well as for recovery in case of the ripple effect. One of the challenges in implementing these methods is the right balance of resilience and efficiency (Aldrighetti et al., 2021, Dolgui et al., 2022b, Ivanov, 2022a, Ivanov, 2022c; Li et al., 2022b; Alikhani et al., 2023; Babai et al., 2023). A specific topic in ripple effect research has been reverse logistics and closed-loop supply chains uncovering additional opportunities and challenges arising from reverse flows (Ivanov et al., 2017; Pavlov et al., 2019, Özçelik et al., 2021, Park et al., 2022).

Most recently, ripple effects driven by simultaneous disruptions in supply, demand, logistics, and capacities have been examined predominantly triggered by the COVID-19 pandemic (Ivanov, 2020, Singh et al., 2021; Ghadge et al., 2022; Hosseini & Ivanov, 2022a; Brusset et al., 2022; Delasay et al., 2022; Ramani et al., 2022). These studies indicated differences in managing the ripple effect under singular disruptive events and long-term crises. They concluded that ripple effect control under crisis is complicated by simultaneous disruptions in supply, demand, and capacities, recovery in the presence of disruptions, and unpredictable scaling of disruptions.

Methods used for ripple effect analysis include discrete event simulation (Schmitt et al., 2017, Ivanov, 2021b, Rozhkov et al., 2022; Ivanov, 2022d; Timperio et al., 2022), system dynamics simulation (Ghadge et al., 2022), agent-based simulation (Li et al., 2021a, b), Bayesian networks (Ojha et al., 2018; Hosseini et al., 2020; Liu et al., 2021), optimal control (Ivanov et al., 2014a; Brusset et al., 2022), fuzzy logic (Pavlov et al., 2022), network theory (Li et al., 2020a, b), and optimization (Gholami-Zanjani et al., 2021; Liu et al., 2022; Sawik, 2022).

2.2 ISNs and network-of networks

Ivanov and Dolgui (2020) framed the notion of Intertwined Supply Network (ISN) concept considering intersecting supply chains in different industries and ecosystems. They used a game-theoretical ecological model to show that intertwining as an adaptation strategy can help ensure viability during a large-scale crisis. Wang and Yao (2023) proposed an optimization model for ISN design under disruptions. Feizabadi et al. (2023) studied the jury-rigging perspective to examine ISN resilience. A similar approach has been proposed by Chopra et al. (2021) based on using multi-level commons which is ”a set of pooled resources for the flow of information, product, or funds”. They note that ”companies that used multiple channels to improve efficiency when facing day-to-day demand-and-supply variations found that the structure also offered resilience without additional cost when COVID struck”.

Ballot et al. (2014) developed a Physical Internet notion, which combines principles and technologies to manage supply chains from the perspective of networking logistics networks. Pan et al. (2017) has developed this idea further applying principles of data networks in digital internet for physical networks. Niu et al. (2019) note that Apple and Samsung play roles of both suppliers and competing firms in two different intersecting supply chains. They developed a game-theoretic study to analyse component sourcing quantity allocation in such settings. Choi et al. (2020), MacCarthy and Ivanov (2022), Ivanov (2022b), Ivanov et al. (2022), and Zhang et al. (2022) point to collaborative and intertwined business ecosystems forming cloud and digital supply chains and platforms responsible for securing society’s needs in line with natural, economic, and governance interests.

ISNs add flexibility required for adaptation. Flexibility has been proven to be one of the central capabilities to adapt and recovery after disruptions (Shekarian et al., 2020). The principal ideas of the viable supply chain and ISN are “adaptable structural supply chain designs for situational supply-demand allocations and, most importantly, the establishment and control of adaptive mechanisms for transitions between the structural designs” (Ivanov, 2022b).

2.3 Collaborative disruption response

Collaboration has been indicated to be an important capability to manage disruptions (Dolgui & Proth, 2010; Scholten & Schilder, 2015; Hedenstierna et al., 2019, Nguyen et al., 2019, Duong & Chong, 2020; Li et al., 2022c). In reality, supply chains of different sectors and ecosystems are not entirely separated from each other. They usually intersect at several points sharing common suppliers and warehouses (Niu et al., 2019; Zhao et al., 2019; Azadegan & Dooley, 2021; (Li et al., 2021b). For example, automotive industry suppliers are at the same time producers of valves for ventilators leading to intertwining of supply chains in automotive and healthcare ecosystems (Ivanov, 2021a). Hedenstierna et al. (2019) elaborate on the economies of collaboration stressing the responsiveness of build-to-order operations. Gupta et al. (2021) examined the impact of disruption timing on decisions to substitute a missing product by another with similar properties produced by a backup supplier. Li et al. (2022a, e, (2023) elaborated on the recovery strategies in the presence of price dynamics and uncertain disruption duration. Müller et al. (2022) described ad-hoc intertwining of commercial and healthcare supply chains as a response to COVID-19 pandemic and medical equipment shortages. They point to the importance of coordination and timing in collaborative emergency response. Shi et al. (2022) provide a survey of recent literature dealing with the ripple effect from a collaboration perspective.

Summarizing our literature review, it can be concluded that literature is rich on the ripple effect in supply chains, understanding its mechanisms and proposing mitigation and recovery strategy. Driven by the pandemic and other instabilities faced through global geopolitical conflicts, shortages of critical components (e.g., semiconductors), and economy and energy crisis, the focus of analysis has been shifted toward ISNs and their viability. However, to the best of our knowledge, none of the previously published research has examined the ripple effect in the ISNs – a distinct and substantial contribution made by our study. To close this research gap, we explore the effects of collaborative disruption responses on the ripple effect in ISNs.

3 Simulation model

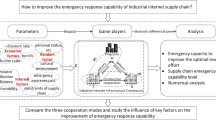

Ripple effect analysis in combination with the ISN context results in a highly dynamic system with uncertainties. Following (Dolgui et al., 2018; Llaguno et al., 2022; Ivanov et al., 2023), simulation is best-suited method for such analysis. Our discrete-event simulation model is developed in anyLogistix software. In the ISN considered for modelling, there are three supply chains of firms representing different industries (Fig. 1).

Firms produce three different products serving three non-connected markets. However, all three producers of final products P1-P3 use a common material M1, which is delivered by a common supplier. Moreover, some technological intertwining is possible. In particular, firm 1 in industry 1 produces a material M12, which can be used as a substitute in industry 2. Similarly, firm 2 can produce a substitute M23 for industry 3, and firm 3 can supply industry 1 with a substitute material M31. Firms also collaborate on inventory management and can share with each other inventory of M1 in case of need.

The following assumptions have been done for setting up the simulation model:

-

1)

Demand is normalized to 1 unit, and each customer places order of one unit of demand every three days at firms 1–3.

-

2)

No back-ordering is possible so if a customer order is not fulfilled on-time, the order is lost and cannot be delivered later.

-

3)

An order is considered to be fulfilled on time if it is delivered within five days after placing an order at factory (so called expected lead time).

-

4)

Order-up-to-level inventory control system is used in all the supply chains, whereas the re-order point equals two units, and the target inventory equals 4 units. For warming-up the simulation, we allow for four units of initial stock at all echelons of supply chains.

-

5)

Production of substitute material for another industry does not affect production utilization and capacity at a site; in other words, no capacity constraints are considered.

-

6)

Bill-of-materials of all three products P1-Pcontains material M1

-

7)

Lead time between supplier and factories is two days, between factories and customers – four days, and between factories– four days.

-

8)

For analysis, a period of four months is used from January 6, 2023 to May 5, 2023.

-

9)

There is a disruption event at supplier starting at March 5, 2023 with a recovery period of 60 days during which supplier 1 is unavailable.

-

10)

For ripple effect analysis, the demand fulfillment indicator is used. It counts the number of products delivered at the customer on time.

4 Experimental results

We structure simulation results in three parts as follows:

-

a baseline scenario without any collaboration between supply chains.

-

impact of collaboration on ripple effect mitigation.

-

impact of adaptation speed of collaborative emergency response on ripple effect mitigation.

4.1 Baseline scenario

In this scenario, there is a supplier disruption, and no collaboration between supply chains is considered as a response reaction (Fig. 2).

First, we show the results of a disruption-free performance, and then the results in the disruption case (Figs. 3 and 4, respectively).

When comparing Figs. 3 and 4, it can be observed that the supplier disruption causes the ripple effect indicated by a significant reduction of the fulfilled demand (a reduction from 114 to 78 units). While the existing inventory allows covering demand at the beginning of the disruption period, a backlog begins growing 12 days after the supplier disruption. We note that the left-hand side inventory diagrams in Figs. 3 and 4 illustrate available inventory and backlog dynamics for material M1 while the right-hand side inventory diagrams in Figs. 3 and 4 illustrate available inventory dynamics for final products P1-P3 (since no backordering is allowed in the model, there is no backlog for final products).

4.2 Collaboration impact on ripple effect mitigation

In this part of experiments, we examine the ISN collaboration impact on the ripple effect. In particular, we now allow for:

-

inventory sharing among manufacturers,

-

capacity re-purposing and usage of substitute materials (through usage of backup technology plans).

After a disruption at the supplier, the factories first share inventories of M1, then increase capacity to produce a substitute product, and finally utilize capacity re-purposing. In particular, the adaptation algorithm first check inventory availability for M1 and re-allocates it to the demand points. If no M1 inventory is available, the algorithm increases production capacity. As the last measure, capacity is re-purposed. The results are shown in Fig. 5.

It can be observed in Fig. 5 that collaboration efforts allow mitigating the ripple effect and even improve the baseline performance to some extent. While results shown in Fig. 5 assume an immediate re-purposing of supply chains, even in a very well-coordinated ISN, some reaction delays can happen. As such, we now investigate the impact of adaptation time (i.e., TTA – time-to-adapt (Ivanov, 2021a)). Figures 6 and 7 depict simulation results of sensitivity analysis regarding TTA.

When analysing results shown in Figs. 5–7, it can be observed that TTA has an immediate impact on ripple effect mitigation through collaboration efforts. While TTA of two weeks is enough to mitigate the ripple effect, a four-week TTA results in some ripple effect reflected in the reduction of fulfilled demand. However, the ripple effect is much less as compared to non-collaborative scenario (Fig. 3).

5 Theoretical and managerial insights

The anyLogistix model proposed in the paper can help design and investigate adaptation scenarios for ripple effect mitigation in the ISN. It illustrates and generalizes the problem of a collaborative emergency adaptation considering multiple intersecting supply chains. The model allows not only to promptly propose an adaptation plan and its deployment in an emergency case but also, and most importantly, to generalize and illustrate the requirements on data and coordination mechanism during a collaborative emergency response.

Our results indicate that collaborative emergency adaptation can help mitigate the ripple effect in ISNs. The results allows us to generalize the notion of collaborative emergency response as a composition of a digital supply chain, structural and process preparedness, and collaborative response (Table 1).

The principles of collaborative emergency response implementation in practice shown in Table 1 can be described as follows. We have shown that the proposed approach has benefits to improve responsiveness of a disruption response through cross-industry collaboration. Concrete implementation actions are preparedness, coordination, emergency capacity re-purposing and stock re-allocation, and collaborative recovery deployment. First, we observed that a collaborative adaptation helps attain a timely disruption response in a cross-industry setting utilizing synergies in the ISNs (e.g., inventory sharing, capacity re-purposing, and usage of substitute materials). The second observation is that adaptation success depends on the timing of response deployment. Some preparedness in the form of backup technology plans, visibility, and digital collaboration platforms helps to improve responsiveness of the adaptation deployment. Third, our analysis notes the importance of visibility of relevant SC data and timely pre-allocation / re-purposing of the ISN structures, processes, and products based on coordination between different supply chains.

6 Conclusions

Ripple effect became one of the major stressors to supply chain resilience. While considerable progress in ripple effect research with the focus on firm’s supply chains can be observed, the literature is still silent about the ripple effect in ISNs. ISNs span supply networks of different industries and ecosystems that have common suppliers, logistics capacities, and warehouses whereas companies can play the role of buyers in one network, and the role of suppliers – in another one.

In this paper, for the first time, the ripple effect was examined in the ISN setting. Through simulations, we modelled the disruption propagation in supply chains having common suppliers (contractual manufacturers) and warehouses. We illustrated our approach with anyLogistix simulations and deduce some generalized theoretical and managerial insights on how and when a collaborative emergency adaptation can help improve supply chain resilience. We explored conditions under which a collaborative coordination of shared/re-purposed capacities and stocks can help mitigate the ripple effect and improve recovery performance of supply chains. As a result, we conceptualized the notion of collaborative emergency adaptation as a composition of a digital supply chain, structural and process preparedness, and collaborative response. Using the model, we demonstrated a superiority of the proposed collaborative response when compared to non-collaborative recovery actions of individual supply chains. With these results, our study contributes to development of “network-of networks” and viability perspective in supply chain resilience management.

Limitations of our study belong to contextual nature of insights deduced from simulations rather than from analytical derivations. Besides, a detailed analysis of contributions of individual ISN capabilities (i.e., visibility, re-purposing and inventory sharing) to performance improvement remained outside of this study.

In future, some extensions of our study can be considered. First, ISN adaptation is frequently based on resources sharing and pooling. For example, inventory sharing is indeed a way to mitigate the ripple effects, but since the entire ISN system includes multiple different industries (and their supply chains), the relationships between supply chains are also relatively complex. As such, consideration of competition and cooperation between different supply chains can lead to interesting conclusions and game-theoretical models. Second, new digital twin-based and artificial intelligence-based methods can be explored to detect intersections of supply chains and shared resources (Ivanov et al., 2019a; Burgos & Ivanov, 2021, Ivanov & Dolgui, 2021a, Dubey et al., 2021a, Dubey 2021b, Kosasih & Brintrup, 2021, Kegenbenkov and Jackson 2021, Rolf et al., 2022).

Importance of ISN-based analysis will grow in next years in light of the digital supply chains, platforms, shortage economy, and Industry 5.0 MacCarthy & Ivanov, 2022; (Ivanov & Dolgui, 2022b, Ivanov and Keskin, 2023, Li et al., 2022d). In these settings, novel settings are offered for research, e.g., contracting in the ISN, stress-tests of intertwined network design, inventory and product control policies with consideration of intertwining effects, dual/backup sourcing policies with material substitution, to name a few. The ISN context allows producing novel and substantial contributions and we expect more developments in this area in next years (Ivanov, 2023, Brusset et al., 2023).

References

Aldrighetti, R., Battini, D., Ivanov, D., & Zennaro, I. (2021). Costs of resilience and disruptions in supply chain network design models: A review and future research directions. International Journal of Production Economics, 235, 108103.

Alikhani, R., Ranjbar, R., Jamali, A., Torabi, S. A., & Zobel, C. W. (2023). Towards increasing synergistic effects of resilience strategies in supply chain network design. Omega, 116, 102819.

Azadegan, A., & Dooley, K. J. (2021). A typology of supply network resilience strategies: Complex collaborations in a complex world. Journal of Supply Chain Management, 57(1), 17–26.

Babai, M. Z., Ivanov, D., & Kwon, O. K. (2023). Optimal Ordering Quantity under Stochastic Time-Dependent price and demand with a supply disruption: A solution based on the change of measure technique. Omega, 116, 102817.

Ballot, E., Montreuil, B., & Meller, R. (2014). The physical internet. La Documentation Francaise).

Brusset, X., Davari, M., Kinra, A., & La Torre, D. (2022). Modelling ripple effect propagation and global supply chain workforce productivity impacts in pandemic disruptions. International Journal of Production Research. https://doi.org/10.1080/00207543.2022.2126021.

Brusset X., Ivanov, D., Jebali, A., & La Torre, D., Repetto, M. (2023). A dynamic approach to supply chain reconfiguration and ripple effect analysis in an epidemic. International Journal of Production Economics, 263, 108935.

Burgos, D., & Ivanov, D. (2021). Food Retail Supply Chain Resilience and the COVID-19 pandemic: A Digital Twin-Based impact analysis and improvement directions. Transportation Research – Part E: Logistics and Transportation Review, 152, 102412.

Choi, T. M. (2021). Fighting against COVID-19: What Operations Research can help and the sense-and-respond Framework. Annals of Operations Research. https://doi.org/10.1007/s10479-021-03973-w.

Choi, T. M., Zhang, J., & Cai, Y. J. (2020). Consumer-to-consumer digital-product-exchange in the sharing economy system with risk considerations: Will digital-product-developers suffer? IEEE Transactions on Systems Man and Cybernetics: Systems, 50(12), 5049–5057.

Chopra, S., Sodhi, M., & Lücker, F. (2021). Achieving supply chain efficiency and resilience by using multi-level commons. Decision Sciences, 52(4), 8817–8832.

Delasay, M., Jain, A., & Kumar, S. (2022). Impacts of the COVID-19 pandemic on Grocery Retail Operations: An Analytical Model. Production and Operations Management, 31(5), 2237–2255.

Deng, X., Yang, X., Zhang, Y., Li, Y., & Lu, Z. (2019). Risk propagation mechanisms and risk management strategies for a sustainable perishable products supply chain. Computers and Industrial Engineering, 135, 1175–1187.

Dolgui, A., & Ivanov, D. (2021). Ripple Effect and Supply chain disruption management: New Trends and Research directions. International Journal of Production Research, 59(1), 102–109.

Dolgui, A., & Proth, J. M. (2010). Supply chain engineering: Useful methods and techniques. London: Springer.

Dolgui, A., Ivanov, D., & Sokolov, B. (2018). Ripple effect in the supply chain: An analysis and recent literature. International Journal of Production Research, 56(1–2), 414–430.

Dolgui, A., Ivanov, D., & Rozhkov, M. (2020a). Does the ripple effect influence the bullwhip effect? An integrated analysis of structural and operational dynamics in the supply chain. International Journal of Production Research, 58(5), 1285–1301.

Dolgui, A., Ivanov, D., & Sokolov, B. (2020b). Reconfigurable supply chain: The X-Network. International Journal of Production Research, 58(13), 4138–4163.

Dubey, R., Bryde, D. J., Blome, C., Roubaud, D., & Giannakis, M. (2021a). Facilitating artificial intelligence powered supply chain analytics through alliance management during the pandemic crises in the B2B context. Industrial Marketing Management, 96, 135–146.

Dubey, R., Gunasekaran, A., Childe, S. J., Wamba, S. F., Roubaud, D., & Foropon, C. (2021b). Empirical investigation of Data Analytics Capability and Organizational Flexibility as Complements to Supply Chain Resilience. International Journal of Production Research, 59(1), 110–128.

Duong, L. N. K., & Chong, J. (2020). Supply chain collaboration in the presence of disruptions: A literature review. International Journal of Production Research, 58(11), 3488–3507.

Feizabadi, J., Gligor, D. M., & Choi, T. Y. (2023). Examining the resiliency of intertwined supply net-works: A jury-rigging perspective. International Journal of Production Research, 61(8), 2432–2451.

Garvey, M. D., Carnovale, S., & Yeniyurt, S. (2015). An analytical framework for supply network risk propagation: A bayesian network approach. European Journal of Operational Research, 243(2), 618–627.

Ghadge, A., Dani, S., Chester, M., & Kalawsky, R. (2013). A systems thinking approach for modelling supply chain risk propagation. Supply Chain Management: An International Journal, 18(5), 523–538.

Ghadge, A., Er, M., Ivanov, D., & Chaudhuri, A. (2022). Visualisation of ripple effect in supply chains under long-term, simultaneous disruptions: A System Dynamics approach. International Journal of Production Research, 60(20), 6173–6186.

Gholami-Zanjani, S. M., Klibi, W., Jabalameli, M. S., & Pishvaee, M. S. (2021). A robust location-inventory model for Food Supply Chains operating under disruptions with Ripple Effects. International Journal of Production Research, 59(1), 301–324.

Gupta, V., Ivanov, D., & Choi, T. M. (2021). Competitive pricing of substitute products under supply disruption. Omega, 101, 102279.

Hägele, S., Grosse, E., & Ivanov, D. (2023). Supply chain resilience: A tertiary study. International Journal of Integrated Supply Management, 16(1), 52–81.

Han, J., & Shin, K. S. (2016). Evaluation mechanism for structural robustness of supply chain considering disruption propagation. International Journal of Production Research, 54(1), 135–151.

Hedenstierna, C. P. T., Disney, S. M., Eyers, D. R., Holmström, J., Syntetos, A. A., & Wang, X. (2019). Economies of collaboration in build-to-model operations. Journal of Operations Management, 65(8), 753–773.

Hosseini, S., & Ivanov, D. (2022a). A multi-layer bayesian network method for supply chain disruption modelling in the wake of the COVID-19 pandemic. International Journal of Production Research, 60(17), 5258–5276.

Hosseini, S., & Ivanov, D. (2022b). A new resilience measure for supply networks with the ripple effect considerations: A bayesian network approach. Annals of Operations Research, 319, 581–607.

Hosseini, S., Ivanov, D., & Dolgui, A. (2019). Review of quantitative methods for supply chain resilience analysis. Transportation Research: Part E, 125, 285–307.

Hosseini, S., Ivanov, D., & Dolgui, A. (2020). Ripple effect modeling of supplier disruption: Integrated Markov Chain and dynamic bayesian Network Approach. International Journal of Production Research, 58(11), 3284–3303.

Iftikhar, A., Ali, I., Arslan, A., et al. (2022). Digital Innovation, Data Analytics, and Supply Chain Resiliency: A bibliometric-based systematic literature review. Ann Oper Res.

Ivanov, D. (2017). Simulation-based ripple effect modelling in the supply chain. International Journal of Production Research, 55(7), 2083–2101.

Ivanov, D. (2019). Disruption tails and revival policies: A simulation analysis of supply chain design and production-ordering systems in the recovery and post-disruption periods. Computers and Industrial Engineering, 127, 558–570.

Ivanov, D. (2020). Predicting the impacts of epidemic outbreaks on global supply chains: A simulation-based analysis on the coronavirus outbreak (COVID-19/SARS-CoV-2) case. Transportation Research Part E: Logistics and Transportation Review, 136, 101922.

Ivanov, D. (2021a). Exiting the COVID-19 Pandemic: After-Shock Risks and Avoidance of Disruption Tails in Supply Chains. Annals of Operations Research, DOI10.1007/s10479-021-04047-7

Ivanov, D. (2021b). Supply chain viability and the COVID-19 pandemic: A conceptual and formal generalisation of four major adaptation strategies. International Journal of Production Research, 59(12), 3535–3552.

Ivanov, D. (2021c). Supply chain viability and the COVID-19 pandemic: A conceptual and formal generalisation of four major adaptation strategies. International Journal of Production Research, 59(12), 3535–3552.

Ivanov, D. (2022a). Lean resilience: AURA (active usage of Resilience Assets) Framework for Post-COVID-19 Supply Chain Management. Int Journal of Logistics Management, 33(4), 1196–1217.

Ivanov, D. (2022b). Viable supply chain model: Integrating agility, resilience and sustainability perspectives – lessons from and thinking beyond the COVID-19 pandemic. Annals of Operations Research, 319, 1411–1431.

Ivanov, D. (2022c). Probability, adaptability and time: Some research-practice paradoxes in supply chain resilience and viability modelling. International Journal of Integrated Supply Management, 15(4), 454–465.

Ivanov, D. (2022d). Blackout and Supply chains: Performance, resilience and viability impact analysis. Annals of Operations Research. 10.1007/s10479-022-04754-9.

Ivanov, D. (2023). The industry 5.0 framework: Viability-based integration of the resilience, sustainability, and human-centricity perspectives. International Journal of Production Research, 61(5), 1683–1695.

Ivanov, D., & Dolgui, A. (2020). Viability of intertwined supply networks: Extending the supply chain resilience angles towards survivability. A position paper motivated by COVID-19 outbreak. International Journal of Production Research, 58(10), 2904–2915.

Ivanov, D., & Dolgui, A. (2021a). A digital supply chain twin for managing the disruptions risks and resilience in the era of industry 4.0. Production Planning and Control, 32(9), 775–788.

Ivanov, D., & Dolgui, A. (2021b). OR-Methods for coping with the ripple effect in supply chains during COVID-19 pandemic: Managerial insights and research implications. International Journal of Production Economics, 232, 107921.

Ivanov, D., & Dolgui, A. (2022a). Stress testing supply chains and creating viable ecosystems. Operations Management Research, 15, 475–486.

Ivanov, D., & Dolgui, A. (2022b). The shortage economy and its implications for supply chain and operations management. International Journal of Production Research, 60(24), 7141–7154.

Ivanov, D. (2023). Intelligent Digital Twin (iDT) for Supply Chain Stress-Testing, Resilience, and Viability. International Journal of Production Economics, 263, 108938.

Ivanov, D., & Keskin, B. (2023). Post-pandemic adaptation and development of supply chain viability theory. Omega, 116, 102806.

Ivanov, D., Sokolov, B., & Dolgui, A. (2014a). The Ripple effect in supply chains: Trade-off ‘efficiency-flexibility-resilience’ in disruption management. International Journal of Production Research, 52(7), 2154–2172.

Ivanov, D., Sokolov, B., & Pavlov, A. (2014b). Optimal distribution (re)planning in a centralized multi-stage network under conditions of ripple effect and structure dynamics. European Journal of Operational Research, 237(2), 758–770.

Ivanov, D., Pavlov, A., Pavlov, D., & Sokolov, B. (2017). Minimization of disruption-related return flows in the supply chain. International Journal of Production Economics, 183, 503–513.

Ivanov, D., Dolgui, A., & Sokolov, B. (2019a). The impact of digital technology and industry 4.0 on the ripple effect and supply chain risk analytics. International Journal of Production Research, 57(3), 829–846.

Ivanov, D., Dolgui, A., & Sokolov, B. (Eds.). (2019b). Handbook of Ripple Effects in the Supply Chain. New York: Springer.

Ivanov, D., Dolgui, A., & Sokolov, B. (2022). Cloud supply chain: Integrating industry 4.0 and Digital Platforms in the “Supply Chain-as-a-Service. Transportation Research – Part E: Logistics and Transportation Review, 160, 102676.

Ivanov, D., Dolgui, A., Blackhurst, J., & Choi, T. M. (2023). Viability of Supply Networks and Ecosystems: Lessons learned from COVID-19 outbreak. International Journal of Production Research, 61(8), 2402–2415.

Katsaliaki, K., Galetsi, P., & Kumar, S. (2022). Supply chain disruptions and resilience: A major review and future research agenda. Annals Of Operations Research, 319, 965–1002.

Kegenbekov, Z., & Jackson, I. (2021). Adaptive supply chain: Demand–supply synchronization using deep reinforcement learning. Algorithms, 14(8), 240.

Kinra, A., Ivanov, D., Das, A., & Dolgui, A. (2020). Ripple effect quantification by supply risk exposure assessment. International Journal of Production Research, 58(19), 5559–5578.

Kosasih, E., & Brintrup, A. (2021). A Machine Learning Approach for Predicting Hidden Links in Supply Chain with Graph neural networks. International Journal of Production Research, 60(17), 5380–5393.

Lei, Z., Lim, M. K., Cui, L., & Wang, Y. (2021). Modelling of risk transmission and control strategy in the transnational supply chain. International Journal of Production Research, 59(1), 148–167.

Levner, E., & Ptuskin, A. (2018). Entropy-based model for the ripple effect: Managing environmental risks in supply chains. International Journal of Production Research, 56(7), 2539–2551.

Li, Y., & Zobel, C. W. (2020). Exploring Supply Chain Network Resilience in the Presence of the Ripple Effect. International Journal of Production Economics, 228, 107693.

Li, Y., Zobel, C. W., Seref, O., & Chatfield, D. C. (2020a). Network characteristics and supply chain resilience under conditions of risk propagation. International Journal of Production Economics, 223, 107529.

Li, G., Liu, M., Bian, Y., & Sethi, S. (2020b). Guarding against disruption risk by contracting under Information Asymmetry. Decision Sciences, 51(6), 1521–1559.

Li, Y., Chen, K., Collignon, S., & Ivanov, D. (2021a). Ripple Effect in the Supply Chain Network: Forward and Backward disruption propagation, Network Health and Firm vulnerability. European Journal of Operational Research, 291(3), 1117–1131.

Li, S., He, Y., & Minner, S. (2021b). Dynamic compensation and contingent sourcing strategies for supply disruption. International Journal of Production Research, 59(5), 1511–1533.

Li, M., Sodhi, M., Tang, C., & Yu, J. (2022a). Preparedness with a system integrating inventory, capacity, and capability for future pandemics and other disasters. Production and Operations Management. 10.1111/poms.13887.

Li, G., Li, X., & Liu, M. (2022b). Inducing supplier backup via Manufacturer Information sharing under Supply disruption risk (p. 108914). Computers & Industrial Engineering.

Li, G., Liu, M., & Zheng, H. (2022c). Subsidization or diversification? Mitigating supply disruption with manufacturer information sharing. Omega, 112, 102670.

Li, G., Xue, J., Li, N., & Ivanov, D. (2022d). Blockchain-supported business model design, supply chain resilience, and firm performance. Transportation Research – Part E: Logistics and Transportation Review, 163, 102773.

Li, S., He, Y., & Zhou, L. (2022e). Dynamic sourcing strategies for supply disruptions under consumer stockpiling. Complex Intell Syst, 8, 4543–4555.

Li, S., He, Y., Huang, H., Lin, J., & Ivanov, D. (2023). Supply chain hoarding and contingent sourcing strategies in anticipation of price hikes and product shortages. IISE Transactions. https://doi.org/10.1080/24725854.2023.2184515.

Liberatore, F., Scaparra, M. P., & Daskin, M. S. (2012). Hedging against disruptions with ripple effects in location analysis. Omega, 40, 21–30.

Liu, M., Liu, Z., Chu, F., Zheng, F., & Chu, C. (2021). A New Robust dynamic bayesian Network Approach for disruption risk Assessment under the Supply Chain Ripple Effect. International Journal of Production Research, 59(1), 265–285.

Liu, M., Liu, Z., Chu, F., Dolgui, A., Chu, C., & Zheng, F. (2022). An optimization approach for multi-echelon supply chain viability with disruption risk minimization. Omega, 112, 102683.

Llaguno, A., Mula, J., & Campuzano-Bolarin, F. (2022). State of the art, conceptual framework and simulation analysis of the ripple effect on supply chains. International Journal of Production Research, 60(6), 2044–2066.

MacCarthy, B., & Ivanov, D. (2022). The digital supply Chain—emergence, concepts, definitions, and technologies. In B. MacCarthy, & D. Ivanov (Eds.), The Digital Supply Chain (pp. 3–14). Amsterdam: Elsevier.

MacCarthy, B., Ahmed, W., & Demirel, G. (2022). Mapping the supply chain: Why, what and how? International Journal of Production Economics, 108688.

Mizgier, K. J., Jüttner, M. P., & Wagner, S. M. (2013). Bottleneck identification in supply chain networks. International Journal of Production Research, 51(5), 1477–1490.

Müller, J., Hoberg, K., & Fransoo, J. (2022). Realizing supply chain agility under time pressure: Ad hoc supply chains during the COVID-19 pandemic. Journal of Operations Management.

Nguyen, W. P. V., & Nof, S. Y. (2019). Collaborative response to disruption propagation (CRDP) in cyber-physical systems and complex networks. Decision Support Systems, 117, 1–13.

Niu, B., Li, J., Zhang, J., Cheng, H. K., & Tan, Y. (2019). Strategic analysis of dual sourcing and dual channel with an unreliable alternative supplier. Production and Operations Management, 28(3), 570–587.

Ojha, R., Ghadge, A., Tiwari, M. K., & Bititci, U. S. (2018). Bayesian network modelling for supply chain risk propagation. International Journal of Production Research, 56(17), 5795–5819.

Osadchiy, N., Gaur, W., & Seshadri, S. (2016). (2021). Systematic Risk in Supply Chain Networks. Management Science, 62(6), 1755–1777.

Osadchiy, N., Schmidt, W., & Wu, J. (2021). (2021). The Bullwhip Effect in Supply Networks. Management Science, 67(10), 6153–6173.

Özçelik, G., Yılmaz, Ö. F., & Yeni, F. B. (2021). Robust optimisation for ripple effect on reverse supply chain: An industrial case study. International Journal of Production Research, 59(1), 245–264.

Pan, S., Ballot, E., Huang, G. Q., & Montreuil, B. (2017). Physical internet and interconnected logistics services: Research and applications. International Journal of Production Research, 55(9), 2603–2609.

Park, Y. W., Blackhurst, J., Paul, C., & Scheibe, K. P. (2022). An analysis of the ripple effect for disruptions occurring in circular flows of a supply chain network. International Journal of Production Research, 60(15), 4693–4711.

Paul, S. K., & Chowdhury, P. (2021). A production recovery plan in manufacturing supply chains for a highdemand item during COVID-19. International Journal of Physical Distribution & Logistics Management, 51, 104–125.

Pavlov, A., Ivanov, D., Pavlov, D., & Slinko, A. (2019). Optimization of network redundancy and contingency planning in sustainable and resilient supply chain resource management under conditions of structural dynamics, Annals of Operations Research, DOI: https://doi.org/10.1007/s10479-019-03182-6

Pavlov, A., Ivanov, D., Werner, F., Dolgui, A., & Sokolov, B. (2022). Integrated detection of disruption scenarios, the ripple effect dispersal and recovery paths in supply chains. Annals of Operations Research, 319, 609–631.

Ramani, V., Ghosh, D., & Sodhi, M. (2022). Understanding systemic disruption from the Covid-19-induced semiconductor shortage for the auto industry. OMEGA: The International Journal of Management Science, 113, 102720.

Rolf, B., Jackson, I., Müller, M., Lang, S., Reggelin, T., & Ivanov, D. (2022). A review on reinforcement learning algorithms and applications in supply chain management. International Journal of Production Research. https://doi.org/10.1080/00207543.2022.2140221.

Rozhkov, M., Ivanov, D., Blackhurst, J., & Nair, A. (2022). Adapting supply chain operations in anticipation of and during the COVID-19 pandemic. Omega, 110, 102635.

Ruel, S., El Baz, J., Ivanov, D., & Das, A. (2021). Supply Chain viability: Conceptualization, measurement, and Nomological Validation. Annals of Operations Research. https://doi.org/10.1007/s10479-021-03974-9.

Sawik, T. (2020). Supply chain disruption management (2nd Edition.). New York: Springer.

Sawik, T. (2022). Stochastic optimization of supply chain resilience under ripple effect: A COVID-19 pandemic related study. Omega, 109, 102596.

Sawik, T. (2023). A stochastic optimization Approach to maintain Supply Chain viability under the Ripple Effect. International Journal of Production Research, 61(8), 2452–2469.

Scheibe, K. P., & Blackhurst, J. (2018). Supply chain disruption propagation: A systemic risk and normal accident theory perspective. International Journal of Production Research, 56(1–2), 43–59.

Schmitt, T. G., Kumar, S., Stecke, K. E., Glover, F. W., & Ehlen, M. A. (2017). Mitigating disruptions in a multi-echelon supply chain using adaptive ordering. Omega, 68, 185–198.

Scholten, K., & Schilder, S. (2015). The role of collaboration in supply chain resilience. Supply Chain Management, 20(4), 471–484.

Shekarian, M., Nooraie, R., & Parast, S. V., M.M (2020). An examination of the impact of flexibility and agility on mitigating supply chain disruptions. International Journal of Production Economics, 220, 107438.

Shi, X., Yuan, X., & Deng, D. (2022). Research on supply network resilience considering the ripple effect with collaboration. International Journal of Production Research, 60(18), 5553–5570.

Sindhwani, R., Jayaram, J., & Saddikuti, V. (2022). Ripple effect mitigation capabilities of a hub and spoke distribution network: An empirical analysis of pharmaceutical supply chains in India. International Journal of Production Research. https://doi.org/10.1080/00207543.2022.2098073.

Singh, S., Kumar, R., Panchal, R., & Tiwari, M. K. (2021). Impact of COVID-19 on logistics systems and disruptions in food supply chain. International Journal of Production Research, 59(7), 1993–2008.

Swierczek, A. (2014). The impact of supply chain integration on the “snowball effect” in the transmission of disruptions: An empirical evaluation of the model. International Journal of Production Economics, 157(1), 89–104.

Tang, L., Jing, K., He, J., & Stanley, H. E. (2016). Complex interdependent supply chain networks: Cascading failure and robustness. Physica A: Statistical Mechanics And Its Applications, 443, 58–69.

Timperio, G., Kundu, T., Klumpp, M., de Souza, R., Loh, X. H., & Goh, K. (2022). Beneficiary-centric decision support framework for enhanced resource coordination in humanitarian logistics: A case study from ASEAN. Transportation Research Part E: Logistics and Transportation Review, 167, 10290.

Wang, M., & Yao, J. (2023). Intertwined supply network design under facility and transportation disruption from the viability perspective. International Journal of Production Research, 61(8), 2513–2543.

Yue, X., Mu, D., Wang, C., Ren, H., & Ghadimi, P. (2022). Topological structure and COVID-19 related risk propagation in TFT-LCD supply networks. International Journal of Production Re-search. https://doi.org/10.1080/00207543.2022.2027039.

Zeng, Y., & Xiao, R. (2014). Modelling of cluster supply network with cascading failure spread and its vulnerability analysis. International Journal of Production Research, 52(23), 6938–6953.

Zhang, G., MacCarthy, B., & Ivanov, D. (2022). The cloud, platforms, and digital twins—enablers of the digital supply chain. In B. MacCarthy, & D. Ivanov (Eds.), The Digital Supply Chain (pp. 77–91). Amsterdam: Elsevier.

Zhao, K., Zuo, Z., & Blackhurst, J. V. (2019). Modelling supply chain adaptation for disruptions: An empirically grounded complex adaptive systems approach. Journal of Operations Management, 65(2), 190–212.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Compliance with ethical standards

No disclosure of potential conflicts of interest, funding, research involving human participants and/or animals, or informed consent exist for this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ivanov, D. Collaborative emergency adaptation for ripple effect mitigation in intertwined supply networks. Ann Oper Res (2023). https://doi.org/10.1007/s10479-023-05408-0

Accepted:

Published:

DOI: https://doi.org/10.1007/s10479-023-05408-0