Abstract

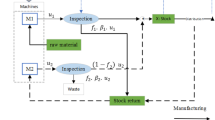

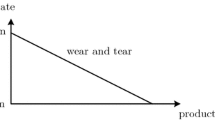

In this paper, a multi-product single-machine economic production quantity model with preventive maintenance, scraped and rework is studied. Shortages are permitted and a fraction of them is backlogged. Capacity and service level are limitations of the production system. It is assumed that preventive maintenance can be performed when the inventory level is positive or negative. Indeed two different scenarios are modeled and according to the comparisons between their costs, a new scenario according to the best time of preventive maintenance is investigated and modeled. The aim of this research is to determine the best time for preventive maintenance, production and back-ordered quantities of each item and common cycle length, such that the expected total cost is minimized. The objective function of the final proposed model is proved to be convex and closed-form optimal solutions are derived. Two numerical examples based on a real application of the proposed model in a turning manufactory with only one computer numerical control machine applied to lathe metal plates to different sizes are used to illustrate the applicability of extended model and proposed solution method.

Similar content being viewed by others

References

Abboud, N. E. (1997). A simple approximation of the EMQ model with Poisson machine failures. Production Planning and Control, 8(4), 385–397.

Aryanezhad, M. B., Noorollahi, E., Karimi-Nasab, M., & Ghoreyshi, S. M. (2010). Batch sizing with random yield and imperfect inspection and process compressibility. In 40th International conference on computers and industrial engineering: Soft computing techniques for advanced manufacturing and service systems, CIE40 2010, Art. No. 5668221.

Berg, M., Posner, M. J. M., & Zhao, H. (1994). Production–inventory systems with unreliable machines. Operations Research, 42, 111–118.

Bielecki, T., & Kumar, P. R. (1988). Optimality of zero-inventory policies for unreliable production facility. Operations Research, 36, 532–541.

Bijari, M., Barzoki, M. R., & Jahanbazi, M. (2007). Effects of imperfect products and rework on lot sizing with work in process inventory. In IIE annual conference and Expo 2007—Industrial engineering’s critical role in a flat world—conference proceedings, pp 919-925.

Cárdenas-Barrón, L. E. (2008). Optimal manufacturing batch size with rework in a single-stage production system—A simple derivation. Computers and Industrial Engineering Journal, 55, 758–765.

Cárdenas-Barrón, L. E. (2009). Economic production quantity with rework process at a single-stage manufacturing system with planned backorders. Computers and Industrial Engineering Journal, 57, 1105–1113.

Chakrabarty, S., & Rao, N. V. (1988). EBQ for a multi stage production system considering rework. Opsearch, 25, 75–88.

Chan, W. M., Ibrahim, R. N., & Lochert, P. B. (2003). A new EPQ model: Integrating lower pricing, rework and reject situations. Production Planning and Control, 14, 588–595.

Chen, K. K., Chiu, Y. S. P., & Hwang, M. H. (2010a). Integrating a cost reduction delivery policy into an imperfect production system with repairable items. International Journal of the Physical Sciences, 5(13), 2030–2037.

Chen, K. K., Chiu, Y. S. P., & Ting, C. K. (2010b). Producer’s replenishment policy for an EPQ model with rework and machine failure taking place in backorder reloading time. WSEAS Transactions on Information Science and Applications, 4, 223–233.

Cheng, F. T., Chang, H. H., & Chiu, S. W. (2010c). Economic production quantity model with backordering. Rework and machine failure taking place in stock piling time. WSEAS Transactions on Information Science and Applications, 4, 463–473.

Chiu, Y. P. (2003). Determining the optimal lot size for the finite production model with random defective rate, the rework process, and backlogging. Engineering Optimization, 35, 427–437.

Chiu, S. W. (2007a). Robust planning in optimization for production system subject to random machine breakdown and failure in rework. Computers and Operations Research, 37, 899–908.

Chiu, S. W. (2007b). Optimal replenishment policy for imperfect quality EMQ model with rework and backlogging. Applied Stochastic Models in Business and Industry., 23, 165–178.

Chiu, S. W. (2008). Production lot size problem with failure in repair and backlogging derived without derivatives. European Journal of Operational Research, 188, 610–615.

Chiu, Y. S. P., Chen, K. K., Cheng, F. T., & Wu, M. F. (2010a). Optimization of the finite production rate model with scrap, rework and stochastic machine breakdown. Computers and Mathematics with Applications, 59, 919–932.

Chiu, S. W., Cheng, C. B., Wu, M. F., & Yang, J. C. (2010b). An algebraic for determining the optimal lot size for EPQ model with rework process. Mathematical and Computational Applications, 15, 364–370.

Chiu, Y. S. P., Chen, K. K., & Ting, C. K. (2012). Replenishment run time problem with machine breakdown and failure in rework. Expert Systems with Applications, 39, 1291–1297.

Chiu, S. W., & Chiu, Y. S. P. (2006). Mathematical modeling for production system with backlogging and failure in repair. Journal of Scientific and Industrial Research, 65, 499–506.

Chiu, S. W., Chiu, Y. P., & Wu, B. P. (2003). An economic production quantity model with the steady production rate of scrap items. The Journal of Chaoyang University of Technology, 8, 225–235.

Chiu, S. W., Gong, D. C., Chiu, C. L., & Chung, C. L. (2011a). Joint determination of the production lot size and number of shipments for EPQ model with rework. Mathematical and Computational Applications, 16, 317–328.

Chiu, S. W., Gong, D. C., & Wee, H. M. (2004). Effects of random defective rate and imperfect rework process on economic production quantity model. Japan Journal of Industrial and Applied Mathematics, 21, 375–389.

Chiu, Y. S. P., Lin, H. D., & Chang, H. H. (2011b). Mathematical modeling for solving manufacturing run time problem with defective rate and random machine breakdown. Computers and Industrial Engineering, 60, 576–584.

Chiu, S. W., Wang, S. L., & Chiu, S. Y. P. (2007). Determining the optimal run time for the EPQ model with scrap, rework, and stochastic breakdowns. European Journal of Operations Research, 180, 664–676.

Chiu, S. W., Yang, J. C., & Kuo, S. Y. C. (2008). Manufacturing Lot-sizing with backordering, scrap, and random breakdown occurring in inventory-stacking period. WSEAS Transactions in Mathematics, 4(7), 183–194.

Chung, K. J. (1997). Bounds for production lot sizing with machine breakdowns. Computers and Industrial Engineering, 32, 139–144.

Chung, K. J. (2003). Approximations to production lot sizing with machine breakdowns. Computers and Operations Research, 30, 1499–1507.

Freimer, M., Thomas, D., & Tyworth, J. (2006). The value of setup cost reduction and process improvement for the economic production quantity model with defects. European Journal of Operational Research, 173, 241–251.

Goyal, S. K., & Cárdenas-Barrón, L. E. (2005). Economic production quantity with imperfect production system. Industrial Engineering Journal, 34, 33–36.

Haji, B., Haji, R., & Ghayoor, Z. (2007). Economic batch quantity with setup time for immediate and delayed rework. In IIE annual conference and Expo 2007–industrial engineering’s critical role in a flat world—conference proceedings (pp. 1666–1671).

Haji, B., Haji, A., & Haji, R. (2009a). Optimal batch production with minimum rework cycles and constraint on accumulated defective units. In 2009 IEEE/INFORMS international conference on service operations, logistics and informatics, SOLI 2009, Art. no. 5204011 (pp. 633–638).

Haji, B., Haji, R. and Haji, A. (2009b). Optimal batch production with rework and non-zero setup cost for rework. In International conference on computers and industrial engineering, Paris, France (pp. 857–862).

Haji, A., & Haji, B. (2010). Optimal batch production for a single machine system with accumulated defectives and random rate of rework. Journal of Industrial and Systems Engineering, 3, 243–256.

Haji, B., Haji, A., & Rahmati, Tavakol A. (2008a). Scheduling accumulated rework in a normal cycle: Optimal batch production with minimum rework cycles. Journal of Industrial and Systems Engineering, 2, 236–249.

Haji, R., Haji, A., Sajadifar, M., & Zolfaghari, S. (2008b). Lot sizing with non-zero setup times for rework. Journal of Systems Science and Systems Engineering, 17, 230–240.

Haji, A., Sikari, S. S., & Shamsi, R. (2010). The effect of inspection errors on the optimal batch size in reworkable production systems with scraps. International Journal of Product Development, 10, 201–216.

Hayek, P. A., & Salameh, M. K. (2001). Production lot sizing with the reworking of imperfect quality items produced. Production Planning and Control, 12, 584–590.

Hou, K. L. (2007). An EPQ model with setup cost and process quality as functions of capital expenditure. Applied Mathematical Modelling, 31, 10–17.

Huang, Y. F. (2006). The effect of service constraint on EPQ model with random deffective rate. Mathematical Problems in Engineering. doi:10.1155/MPE/2006/79028.

Jaber, M. Y., Bonney, M., & Moualek, I. (2009). An economic order quantity model for an imperfect production process with entropy cost. International Journal of Production Economics, 118, 26–33.

Jaber, M. Y., Goyal, S. K., & Imran, M. (2008). Economic production quantity model for items with imperfect quality subject to learning effects. International Journal of Production Economics, 115, 143–150.

Jamal, A. M. M., Sarker, B. R., & Mondal, S. (2004). Optimal manufacturing batch size with rework process at a single-stage production system. Computers and Industrial Engineering, 47, 77–89.

Lee, H. L., Chandra, M. J., & Deleveaux, V. J. (1997). Optimal batch size and investment in multistage production systems with scrap. Production Planning and Control, 8, 586–596.

Lee, H. L., & Rosenblatt, M. (1987). Simultaneous determination of production cycle and inspection schedules in a production system. Management Sciences, 33, 1125–1136.

Liao, G. L., Chen, Y. H., & Sheu, S. H. (2009). Optimal economic production quantity policy for imperfect process with imperfect repair and maintenance. European Journal of Operational Research, 195, 348–357.

Liao, G. L., & Sheu, S. H. (2011). Economic production quantity model for randomly failing production process with minimal repair and imperfect maintenance. International Journal of Production Economics, 130, 118–124.

Noorollahi, E., Karimi-Nasab, M., & Aryanezhad, M. B. (2012). An economic production quantity model with random yield subject to process compressibility. Mathematical and Computer Modeling, 56, 80–96.

Parveen, M., & Rao, T. V. V. L. N. (2009). Optimal batch sizing, quality improvement and rework for an imperfect production system with inspection and restoration. European Journal of Industrial Engineering, 3, 305–335.

Pasandideh, S. H. R., Niaki, S. T. A., & Mirhosseini, S. S. (2010). A parameter-tuned genetic algorithm to solve multi-product economic production quantity model with defective items, rework, and constrained space. International Journal of advanced Manufacturing Technology, 49(5–8), 827–837.

Sana, S. S. (2010a). A production–inventory model in an imperfect production process. European Journal of Operational Research, 200, 451–464.

Sana, S. S. (2010b). An economic production lot size model in an imperfect production system. European Journal of Operational Research, 201, 158–170.

Sana, S. S., & Chaudhuri, K. S. (2010). An EMQ model in an imperfect production process. International Journal of Systems Science, 41, 635–646.

Sarkar, B., Sana, S. S., & Chaudhuri, K. S. (2010). Optimal reliability, production lot size and safety stock in an imperfect production system. International Journal of Mathematics in Operational Research, 2, 467–490.

Sarkar, B., Sana, S. S., & Chaudhuri, K. (2011). An imperfect production process for time varying demand with inflation and time value of money—An EMQ model. Expert Systems with Applications, 38, 13543–13548.

Sarker, B. R., Jamal, A. A. M., & Mondal, S. (2008). Optimal batch sizing in a multi-stage production system with rework consideration. European Journal of Operational Research, 184, 915–929.

Shi, J., Katehakis, M. N., & Melamed, B. (2013). Martingale methods for pricing inventory penalties under continuous replenishment and compound renewal demands. Annals of Operations Research, 208(1), 593–612.

Shi, J., Katehakis, M. N., Melamed, B., & Xia, Y. (2014). Optimal continuous replenishment for inventory systems with compound Poisson demands and lost-sales. Operations Research, 6(5), 1048–1063.

Taheri-Tolgari, J., Mirzazadeh, A., & Jolai, F. (2012). An inventory model for imperfect items under inflationary conditions with considering inspection errors. Computers and Mathematics with Applications, 63, 1007–1019.

Taleizadeh, A. A. (2014). An economic order quantity model with partial backordering and advance payments for an evaporating item. International Journal of Production Economic, 155, 185–193.

Taleizadeh, A. A., Barzinpour, F., & Wee, H. M. (2011a). Meta-heuristic algorithms to solve the fuzzy single period problem. Mathematical and Computer Modeling, 54(5–6), 1273–1285.

Taleizadeh, A. A., Cardenas-Barron, L. E., & Mohamamdi, B. (2012a). Multi product single machine EPQ model with backordering, scraped products, rework and interruption in manufacturing process. International Journal of Production Economic, 150, 9–27.

Taleizadeh, A. A., Moghadasi, H., Niaki, S. T. A., & Eftekhari, A. K. (2009). An EOQ-joint replenishment policy to supply expensive imported raw materials with payment in advance. Journal of Applied Science, 8(23), 4263–4273.

Taleizadeh, A. A., Najafi, A. A., & Niaki, S. T. A. (2010a). Economic production quantity model with scraped items and limited production capacity. Scientia Iranica, 17, 58–69.

Taleizadeh, A. A., & Nematollahi, M. R. (2014). An inventory control problem for deteriorating items with backordering and financial engineering considerations. Applied Mathematical Modeling, 38, 93–109.

Taleizadeh, A. A., Niaki, S. T., & Aryanezhad, M. B. (2008). Multi-product multi-constraint inventory control systems with stochastic replenishment and discount under fuzzy purchasing price and holding costs. American Journal of Applied Science, 8(7), 1228–1234.

Taleizadeh, A. A., Niaki, S. T. A., & Aryanezhad, M. B. (2010b). Replenish-up-to multi chance-constraint inventory control system with stochastic period lengths and total discount under fuzzy purchasing price and holding costs. International Journal of System Sciences, 41(10), 1187–1200.

Taleizadeh, A. A., Niaki, S. T. A., Aryanezhad, M. B., & Fallah-Tafti, A. (2010c). A genetic algorithm to optimize multi-product multi-constraint inventory control systems with stochastic replenishments and discount. International Journal of Advanced Manufacturing Technology, 51(1–4), 311–323.

Taleizadeh, A. A., Niaki, S. T. A., & Najafi, A. A. (2010d). Multi-product single-machine production system with stochastic scrapped production rate, partial backordering and service level constraint. Journal of Computational and Applied Mathematics, 233, 1834–1849.

Taleizadeh, A. A., & Pentico, D. W. (2013). An economic order quantity model with known price increase and partial backordering. European Journal of Operational Research, 28(3), 516–525.

Taleizadeh, A. A., & Pentico, D. W. (2014). An economic order quantity model with partial backordering and all-units discount. International Journal of Production Economic, 155, 172–184.

Taleizadeh, A. A., Pentico, D. W., Aryanezhad, M. B., & Ghoreyshi, M. (2012b). An economic order quantity model with partial backordering and a special sale price. European Journal of Operational Research, 221(3), 571–583.

Taleizadeh, A. A., Pentico, D. W., Jabalameli, M. S., & Aryanezhad, M. B. (2013a). An economic order quantity model with multiple partial prepayments and partial backordering. Mathematical and Computer Modeling, 57(3–4), 311–323.

Taleizadeh, A. A., Sadjadi, S. J., & Niaki, S. T. A. (2010e). Multi-product EPQ model with single machine, backordering and Immediate rework process. European journal of Industrial Engineering, 5, 388–411.

Taleizadeh, A. A., Wee, H. M., & Jalali-Naini, S. G. R. (2013b). Economic production quantity model with repair failure and limited capacity. Applied Mathematical Modeling, 37(5), 2765–2774.

Taleizadeh, A. A., Wee, H. M., & Sadjadi, S. J. (2010f). Multi-product production quantity model with repair failure and partial backordering. Computers and Industrial Engineering, 59, 45–54.

Taleizadeh, A. A., Widyadana, G. A., Wee, H. M., & Biabani, J. (2011b). Multi products single machine economic production quantity model with multiple batch size. International Journal of Industrial Engineering Computations, 2, 213–224.

Ting, C. K., Chiu, Y. S. P., & Chan, C. C. H. (2011). Optimal lot sizing with scrap and random breakdown occurring in backorder replenishment period. Mathematical and Computational Applications, 16, 329–339.

Wee, H. M., & Chung, C. J. (2009). Optimizing replenishment policy for an integrated production inventory deteriorating model considering green component-value design and remanufacturing. International Journal of Production Research, 47(5), 1343–1368.

Wee, H. M., Yu, Jonas, & Chen, M. C. (2007). Optimal inventory model for items with imperfect quality and shortage backordering. Omega, 35, 7–11.

Yoo, S. H., Kim, D. S., & Park, M. S. (2009). Economic production quantity model with imperfect-quality items, two-way imperfect inspection and sales return. International Journal of Production Economics, 121, 255–265.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix (A): Holding cost of perfect items

From Eq. (40),

Knowing \(X_i =P_i -\varphi _i -d_i \)and assuming \(U_i =P_i^1 -\varphi _i^1 -d_i \) we have;

finally,

Appendix (B): Cyclic objective function

We know,

after some simplifications the cyclic total cost function is:

Appendix (C): Convexity of objective function

Appendix (D): Deriving the optimal solution

Setting the first derivative of objective function respect to T equal to zero gives;

And setting the first derivative of objective function respect to \(b_i\) equal to zero gives;

Substituting (D2) in (D1) yields;

Rights and permissions

About this article

Cite this article

Taleizadeh, A.A. A constrained integrated imperfect manufacturing-inventory system with preventive maintenance and partial backordering. Ann Oper Res 261, 303–337 (2018). https://doi.org/10.1007/s10479-017-2563-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10479-017-2563-7