Abstract

Carbonaceous adsorbents were obtained from the residue after supercritical extraction of marigold subjected to physical activation and used as nitrogen dioxide and iodine adsorbents. The effect of carbonisation and activation temperature on the textural parameters, acid–base character of the surface and sorption properties of the activated carbons was tested. The materials obtained were activated carbons of low-developed surface area varying from 2 to 206 m2/g, showing clearly basic character of the surface. The results proved that proper selection of the carbonisation and activation procedure of the residue after supercritical extraction of marigold permitted obtaining carbonaceous adsorbents with good capacity toward liquid as well as gas inorganic pollutants. The effectiveness of NO2 removal was found to depend to large extent on the conditions of adsorption. The preliminary wetting of the adsorbent bed was shown to significantly increase the amount of pollutants removed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

One of the most important measures aimed at protection of the natural environment is restriction of emission of pollutants (Emami and Azizian 2014; Nowicki et al. 2014; Pietrzak and Bandosz 2007; Tyszczuk-Rotko et al. 2014; Wiśniewska 2012; Wiśniewska et al. 2013, Wiśniewska and Szewczuk-Karpisz 2013; Nosal-Wiercińska et al. 2015). One of the most effective methods for elimination of pollutants is their adsorption by activated carbons (Bansal and Goyal 2005; Guo et al. 2013; Nowicki et al. 2013). Thanks to their strongly developed porous structure, activated carbons show very good sorption properties, from both liquid and gas phase and that is why they have been applied in many areas (Aysu and Küçük 2015; Kazmierczak et al. 2013; Nowicki et al. 2008). Continuous broadening of the range of their use leads to increased demands for activated carbon adsorbents, which stimulates the search for new carbon precursors. The most interesting materials (among those previously proposed in literature) are all kinds of post-agricultural waste materials (Achaw and Afrane 2008; Kazmierczak-Razna et al. 2015; Martinéz et al. 2006; Nowicki et al. 2012). Attractive precursors of activated carbons can be also the waste products left after extraction of plant raw materials with supercritical CO2.

The process of supercritical extraction is employed in pharmaceutical, cosmetic, food and fuel industries. It is used for extraction of dyes, aromas, fatty acids, active ingredients of plant origin used in production of cosmetics, or for decaffeination of coffee (Gracia et al. 2007; Hulbert et al. 1998; Mushtaq et al. 2015). The interest in supercritical extraction has been recently increasing and it is expected that the amount of waste products accompanying this process will increase. The possibility of use of such waste for the production of activated carbons seems not only an attractive method of their utilisation but is also an economic method for obtaining effective adsorbents of pollutants from liquid and gas phase (Reverchon 1997; Rój et al. 2013; Zhao and Zhang 2013; del Valle 2015).

In view of the above, the main aim of the study was to obtain the activated carbons by carbonisation and physical activation of the waste left after supercritical extraction of marigold and application of the adsorbents prepared for removal of gas and liquid phase pollutants represented by nitrogen dioxide and iodine. In addition, we studied the effect of the temperature of carbonisation and activation on physicochemical and sorption properties of the activated carbons.

2 Experimental

2.1 Sample preparation

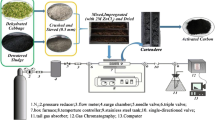

The starting material (M) was the residue after supercritical extraction of marigold in the form of powder with particle size range of 0.10–0.75 mm and moisture content of 4.9 wt%. At first the precursor was subjected to carbonisation process that was carried out in a quartz tubular reactor heated by horizontal furnace, under a stream of nitrogen flown at the rate of 0.170 L/min. The samples were heated (5º/min) from room temperature to the final carbonisation temperature of 500 (M5) and 700 °C (M7). The samples were kept at the maximum temperature for 60 min and then cooled down in inert atmosphere. Carbonisation products were next subjected to physical activation (A). This process was carried out at a temperature of 700 (A7) or 800 °C (A8) under a stream of carbon dioxide flown at the rate of 0.250 L/min, for 60 min.

2.2 Analytical procedures

The elemental analysis of the precursor, carbonisation products and activated carbons was performed by using elemental analyser Vario EL III. The standard test method ASTM D2866-94 (2004) for the ash content determination was applied. The samples were burnt in a microwave oven at 850 °C for 60 min.

The porous structure of activated carbons was characterised by nitrogen adsorption–desorption isotherms measured on Autosorb iQ at −196 °C. The surface area of activated carbons was calculated by Brunauer-Emmett-Teller method. The total pore volume was calculated at a relative pressure of approximately p/p0 = 0.99. The average pore diameter (d) was determined on the basis of surface area (SBET) and the total pore volume (Vt), d = 4Vt/SBET. Furthermore, the micropore volume and micropore area were determined using the t-plot method.

The content of surface oxygen functional groups was determined by the Boehm method Boehm (1994). The pH of activated carbons was measured using the following procedure: 0.2 g of each sample was added to 10 ml of distilled water and the suspension was stirred overnight to reach equilibrium. Then the pH of the suspension was measured on a pH-meter manufactured by Metrohm Ion Analysis (Switzerland) equipped in Unitrode Pt1000 (combined glass pH electrode with temperature sensor).

For the evaluation of NO2 sorption capacity, the samples were tested in two variants: in dry conditions (D) and after pre-humidification of activated carbon’s bed by the air of 70 % humidity for 30 min so in mix-dry conditions (MD). The samples (bed volume 3 cm3) were packed into a glass column. Dry air with 0.1 % of NO2 was passed through the dry or pre-humidified bed of the adsorbent at 0.450 L/min. The breakthrough of NO2 was monitored using Q-RAE PLUS PGM-2000/2020 with electrochemical sensors. The tests were stopped at the breakthrough concentration of 20 ppm (electrochemical sensor limits). After that, the desorption of NO2 from the adsorbent bed was monitored. Additionally, to check the NO2 reduction as a result of its reaction with carbonaceous material, the concentration of NO in the system was also monitored till 200 ppm. The interaction capacities of each sorbent in terms of milligram of NO2 per gram of adsorbent were calculated according to the formula proposed by Nowicki et al. (2010).

The iodine sorption ability of the adsorbents was determined according to the following procedure: Portions of 0.2 g of the samples sieved to a particle size below 1 mm were placed in 250 ml flasks and 4 ml of 5 % HCl was added. Then 20 ml of stock 0.1 M iodine solution was added to it and the mixture was shaken for 4 min in a shaker. All the samples were filtered through filter paper and next washed with 50 ml of water. The resulting solution was titrated with 0.1 M sodium thiosulphate (1 % starch solution as an indicator) until the solution become colourless.

3 Results and discussion

3.1 Elemental composition of the chars and activated carbons

Because of a low contribution of carbon in the initial material, the residue after supercritical extraction of marigold was subjected to carbonisation at two temperatures, 500 or 700 °C, followed by physical activation with CO2 at 700 or 800 °C. According to the data presented in Table 1, the process of carbonisation leads to a considerable increase in the contents of carbon, nitrogen and sulphur relative to the corresponding contents in the initial material (M). Increased content of Cdaf is accompanied by a notable decrease in the contents of hydrogen and oxygen, greater for char M7. The processes taking place on carbonisation of the residue after supercritical extraction of marigold also result in a significant increase in the content of ash; sample M7 has three times higher level of ash than the initial material.

Physical activation with CO2 also induces changes in the elemental composition of the activated carbons obtained. In samples of activated carbons M5A7, M7A7, M7A8, further increase in the content of carbon with respect to that in chars M5 and M7 is observed. Only for M5A8 the content of carbon is by over 13 wt% smaller than that in M5, which can be attributed to excessive burning of carbon under activation at 800 °C. All activated carbons show higher content of Ndaf relative to the precursor and carbonisates, which may follow from the presence of heterocyclic nitrogen groups resistant to the effect of high temperatures. The content of sulphur in the carbon adsorbents obtained is similar, irrespective of the activation temperature. The changes in content of oxygen and hydrogen are more complex. Samples M5A7 and M7A7 show much lower contribution of hydrogen and oxygen than the corresponding chars, whereas samples M5A8 and M7A8, activated at 800 °C, show the reverse tendencies. A drastic increase in Odaf to 32.9 wt% observed in sample M5A8 confirms the earlier assumption of excessive burn of carbon upon activation at this temperature. The process of physical activation causes also a significant increase in the content of mineral substance in the carbon materials obtained, in particular in those activated at 800 °C.

3.2 Textural parameters of the activated carbons

As follows from Table 2 data, physical activation does not permit effective development of surface area, in particular in the samples activated at 700 °C. The surface area of the samples activated at 700 °C varies from 2 to 4 m2/g, so their porous structure was not effectively developed, most probably because of a too small difference between the temperatures of carbonisation and activation. At the present stage of research it cannot be excluded that the majority of pores generated in the process of sample activation was blocked by the mineral substance present in the structure of activation products, which is indicated by high values of the mean pore diameters of 31.7 and 17.7 nm in M5A7 and M7A7, respectively. However, detail explanation of this question needs further study.

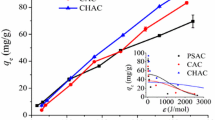

The activation temperature increased by 100 °C brings materials of surface area and pore volume much higher than those of M5A7 and M7A7. The most developed surface area and porous structure shows sample M5A8, obtained by activation of char M5 at 800 °C. Analysis of textural parameters of M5A8 and M7A8 reveals that also the carbonisation temperature has a significant effect on the porous structure of the activated carbons. According to Table 2 data, the activated carbon obtained from M5 char is characterised by twofold greater surface area than analogous sample prepared by activation of the M7 char. Most probably it follows from the fact that the carbon structure of the carbonisate obtained at 700 °C shows much higher ordering, so it is much less susceptible to the activating agent—carbon dioxide. Analysis of Table 2 also implies that samples M5A8 and M7A8 show mesoporous structure with micropores contribution of about 25–35 % in the total pore volume. Considerable predominance of mesopores in the structure of the adsorbents obtained is confirmed by the shape of adsorption/desorption isotherms (in particular by the presence of broad hysteresis loops, see Fig. 1) and the average pore diameter value of 3.6–3.7 nm.

3.3 Acid–base properties of the precursor, chars and activated carbons

According to the results collected in Table 3, the precursor used in the studies shows acidic character of surface as follows from its pH of 4.3 and over four times higher content of acidic than basic groups. Interestingly, the processes of both carbonisation and activation, irrespective of their temperatures, result in removal of acidic groups and a considerable increase in the basic groups. The pH value after thermo-chemical treatment is 10.4–11.6, while the content of basic functional groups varies from 5.01 to 8.37 mmol/g.

The number of basic oxygen groups on the surface depends to a significant degree on the temperature of carbonisation and in particular on that of activation. With increasing temperature of carbonisation, the number of basic groups increases, although the difference between the samples carbonised at 500 and 700 °C is only 0.19 mmol/g. The activation with CO2 results in a further increase in the amount of basic surface groups, especially on the surfaces of samples M5A8 and M7A8, activated at 800 °C. The strongly basic character of the surfaces of activated carbons obtained is probably a consequence of the fact that the activator applied (CO2) and the high temperature of activation are favourable for generation of basic groups (Nowicki et al. 2008).

3.4 Nitrogen dioxide adsorption

None of the carbonisates obtained shows sorption properties towards nitrogen dioxide, both in dry and mix-dry conditions. Fortunately, activated carbons do show them (Table 4), especially when the adsorption was performed in mix-dry conditions (after preliminary wetting of the adsorbent with a stream of wet air of 70 % humidity). The sorption capacities of activated carbons are to a significant degree dependent on the carbonisation and activation temperatures, but first of all on the conditions of adsorption. The most effective adsorbent in dry conditions was sample M7A8 whose sorption capacity of 29.2 mg/g was about twice higher than that of the other samples. Also in mix-dry conditions this sample showed very good sorption capacity. The most effective adsorbent in mix-dry conditions was however, sample M5A7, whose sorption capacity reached over 102.1 mg NO2/gads, which was over six times greater than in the dry conditions (16.3 mg/g). For the other carbon samples studied, preliminary wetting with humid air resulted in only twice increased sorption capacity. Interestingly, a comparison of the data presented in Tables 4 and 5 reveals that although the activated carbon samples obtained have poorly developed porous structure, they show comparable or even better sorption properties towards NO2, than the materials obtained by chemical activation of post-agricultural or post-industrial waste with KOH, characterised by much better textural parameters.

The effect of the carbonisation and activation temperatures on the sorption capacities was different, see Table 4. For the samples activated at 700 °C (M5A7, M7A7), an increase in the carbonisation temperature by 200 °C deteriorates the sorption capacities, both in dry and in mix-dry conditions. For the samples activated at 800 °C, the reverse is true.

Similar shapes of the curves illustrating the changes in NO2 concentration upon adsorption in dry and mix-dry conditions (Fig. 2) suggests that the mechanism of adsorption for the majority of samples is similar. Only for sample M7A8 a different course of the curve was observed for the adsorption in mix-dry conditions in which a slow increase in the concentration of NO2 was noted up to a limiting value of 20 ppm. For the other samples, for a relatively long time the concentration of NO2 was zero, then there was a breakthrough and a rapid increase in NO2 concentration to 20 ppm. According to Fig. 2a and b, the preliminary wetting of the adsorbent with a stream of humid air causes an extension of the time in which the NO2 concentration recorded is zero, which to a certain degree explains the higher sorption capacities of the activated carbons obtained in these conditions. A probable reason for such behaviour in mix-dry conditions is generation of a film of water on the adsorbent surface with which NO2 molecules can react to give HNO3 and HNO5 acids, so the amount of adsorbed nitrogen dioxide increases.

A rapid decrease in NO2 concentration after cutting off its flow to the adsorbent bed suggests that the majority of adsorbed NO2 has been permanently bound in the porous structure of the activated carbons, so it underwent chemisorption. This process is possible thanks to the presence of a considerable content of mineral substance (Table 1) and oxygen functional groups of basic character (Table 3). Only for samples M5A7 and M5A8, when adsorption is performed in mix-dry conditions, rinsing of adsorbent bed with a stream of pure air for 30 min does not permit a decrease in the NO2 concentration to zero ppm.

To characterise in more detail the processes taking place in the adsorbent bed, also the changes in NO concentration were analysed. Nitrogen oxide can be formed as a result of reduction of NO2 upon reaction with oxygen groups and/or carbon matrix. The character of the curves presented in Fig. 3 implies that the effectiveness of NO2 reduction depends on the conditions of adsorption and is the most intense for mix-dry adsorption. What is important, in particular from the ecological point of view, irrespective of the variant of adsorption, for the majority of activated carbon samples, except for samples M5A7 and M5A8 when adsorption was performed in mix-dry conditions, the concentration of NO did not exceed 60 ppm.

3.5 Sorption abilities toward iodine

Analysis of the data presented in Table 5 shows that the temperatures of carbonisation and activation have a significant influence on the effectiveness of iodine removal by the adsorbents studied. With increasing temperature of carbonisation of the initial material, the adsorption capacity towards iodine considerably increases. A similar effect is observed on the temperature of activation increased from 700 to 800 °C. It is probably a consequence of much better developed porous structure and surface area of these samples. The least effective adsorbent towards iodine was char M5, which can only adsorb 417 mg of iodine.

It should be emphasised that the activated carbons obtained by physical activation of chars M5 and M7 at 800 °C are more effective in iodine removal than the commercially available carbons (Table 5) and show the effectiveness comparable to that of the products of chemical activation of such precursors as pistachio nut shells or cherry stones.

4 Conclusions

The above presented results have shown that the residue after supercritical extraction of marigold can be used as precursor for production of effective carbonaceous adsorbents. The activated carbon samples based on this material show much content of mineral matter, not well-developed surface area and a large number of functional groups of basic character. Therefore, further studies should be aimed at optimisation of the textural parameters of the adsorbents obtained so that these materials could be used in near future for effective removal of impurities from gas and liquid phase. The study has also shown that the effectiveness of gas pollutants removal depends first of all on the conditions of adsorption, so their effect should also be a subject of future studies.

References

Achaw, O.W., Afrane, G.: The evolution of the pore structure of coconut shells during the preparation of coconut shell-based activated carbons. Micropor. Mesopor. Mat. 112, 284–290 (2008)

Aysu, T., Küçük, M.M.: Removal of crystal violet and methylene blue from aqueous solutions by activated carbon prepared from Ferula orientalia. Int. J. Environ. Sci. Te. 12, 2273–2284 (2015)

Bansal, RCh., Goyal, M.: Activated Carbon Adsorption. Taylor & Francis Group, Boca Raton (2005)

Boehm, H.P.: Some aspects of the surface chemistry of carbon blacks and other carbons. Carbon 32, 759–769 (1994)

Del Valle, J.M.: Extraction of natural compounds using supercritical CO2: going from the laboratory to the industrial application. J. Supercrit. Fluid. 96, 180–199 (2015)

Emami, Z., Azizian, S.: Preparation of activated carbon from date sphate using microwave irradiation and investigation of its capability for removal of dye pollutant from aqueous media. J. Anal. Appl. Pyrol. 108, 176–184 (2014)

Gracia, I., Rodríguez, J.F., García, M.T., Alvarez, A., García, A.: Isolation of aroma compounds from sugar cane spirits by supercritical CO2. J. Supercrit. Fluid. 43, 37–42 (2007)

Guo, Y., Li, Y., Zhu, T., Ye, M., Wang, X.: Adsorption of SO2 and chlorobenzene on activated carbon. Adsorption 19, 1109–1116 (2013)

Hofman, M., Pietrzak, R.: Adsorbents obtained from waste tires for NO2 removal under dry conditions at room temperature. Chem. Eng. J. 170, 202–208 (2011)

Hulbert, G.J., Biswal, R.N., Walker, T.H., Mehr, C.B., Collins, J.L.: Solid/liquid extraction of caffeine from guaraná with methylene chloride. Food Sci. Technol. Int. 4(1), 53–58 (1998)

Kazmierczak, J., Nowicki, P., Pietrzak, R.: Sorption properties of activated carbons obtained from corn cobs by chemical and physical activation. Adsorption 19, 273–281 (2013)

Kazmierczak-Razna, J., Gralak-Podemska, B., Nowicki, P., Pietrzak, R.: The use of microwave radiation for obtaining activated carbons from sawdust and their potential application in removal of NO2 and H2S. Chem. Eng. J. 269, 352–358 (2015)

Martinéz, M.L., Torres, M.M., Guzmán, C.A., Maestri, D.M.: Preparation and characteristics of activated carbon from olive stones and walnut shells. Ind. Crop. Prod. 23, 23–28 (2006)

Mushtaq, M., Sultana, B., Anwar, F., Adnan, A., Rizvi, S.S.H.: Enzyme-assisted supercritical fluid extraction of phenolic antioxidants from pomegranate peel. J. Supercrit. Fluid. 104, 122–131 (2015)

Nosal-Wiercińska, A., Grochowski, M., Wiśniewska, M., Tyszczuk-Rotko, K., Yilmaz, S., Yagmur, S., Saglikoglu, G., Yanik, S.: Adsorption of selected amino acids at mercury/aqueous solution of chlorate (VII) interface; dependence on the supporting electrolyte concentration. Ads. Sci. Tech. 33, 553–558 (2015)

Nowicki, P., Pietrzak, R., Wachowska, H.: Comparison of physicochemical properties of nitrogen-enriched activated carbons prepared by physical and chemical activation of brown coal. Energy Fuels 22, 4133–4138 (2008)

Nowicki, P., Wachowska, H., Pietrzak, R.: Active carbons prepared by chemical activation of plum stones and their application in removal of NO2. J. Hazard. Mater. 181, 1088–1094 (2010a)

Nowicki, P., Skrzypczak, M., Pietrzak, R.: Effect of activation method on the physicochemical properties and NO2 removal abilities of sorbents obtained from plum stones (Prunus domestica). Chem. Eng. J. 162(2), 723–729 (2010b)

Nowicki, P., Supłat, M., Przepiórski, J., Pietrzak, R.: NO2 removal on adsorbents obtained by pyrolysis and physical activation of corrugated cardboard. Chem. Eng. J. 195, 7–14 (2012)

Nowicki, P., Skibiszewska, P., Pietrzak, R.: NO2 removal on adsorbents prepared from coffee industry waste materials. Adsorption 19, 521–528 (2013)

Nowicki, P., Skibiszewska, P., Pietrzak, R.: Hydrogen sulphide removal on carbonaceous adsorbents prepared from coffee industry waste materials. Chem. Eng. J. 248, 208–215 (2014)

Nowicki, P., Bazan, A., Kazmierczak-Razna, J., Pietrzak, R.: Sorption properties of carbonaceous adsorbents obtained by pyrolysis and activation of pistachio nut shells. Adsorpt. Sci. Technol. 33(6–8), 581–586 (2015)

Pietrzak, R.: Sawdust pellets from coniferous species as adsorbents for NO2 removal. Bioresource. Technol. 101, 907–913 (2010)

Pietrzak, R., Bandosz, T.J.: Reactive adsorption of NO2 at dry conditions on sewage sludge-derived materials. Envir. Sci. Tech. 41, 7516–7522 (2007)

Pietrzak, R., Nowicki, N., Kazmierczak, J., Kuszynska, I., Goscianska, J., Przepiórski, J.: Comparison of the effects of different chemical activation methods on properties of carbonaceous adsorbents obtained from cherry stones. Chem. Eng. Res. Des. 92, 1187–1191 (2014)

Reverchon, E.: Supercritical fluid extraction and fractionation of essential oils and related products. J. Supercrit. Fluid. 10, 1–37 (1997)

Rój, E., Dobrzyńska-Inger, A., Grzęda, K., Kostrzewa, D.: Ekstrakcja nadkrytyczna surowców roślinnych. Przem. Chem. 92, 1358–1363 (2013)

Tyszczuk-Rotko, K., Bęczkowska, I., Nosal-Wiercińska, A.: Simple, selective and sensitive voltammetric method for the determination of herbicide (paraquat) using a bare boron-doped diamond electrode. Diam. Relat. Mater. 50, 86–90 (2014)

Wiśniewska, M.: The temperature effect on the adsorption mechanism of polyacrylamide on the silica surface and its stability. Appl. Surf. Sci. 258, 3094–3101 (2012)

Wiśniewska, M., Szewczuk-Karpisz, K.: Removal possibilities of colloidal chromium (III) oxide from water using polyacrylic acid. Environ. Sci. Pollut. R. 20, 3657–3669 (2013)

Wiśniewska, M., Nosal-Wiercińska, A., Dąbrowska, I., Szewczuk-Karpisz, K.: Effect of the solid pore size on the structure of polymer film at the metal oxide/polyacrylic acid solution interface—temperature impact. Micropor. Mesopor. Mat. 175, 92–98 (2013)

Zhao, S., Zhang, D.: Supercritical fluid extraction and characterisation of Moringa oleifera leaves oil. Sep. Purif. Technol. 118, 497–502 (2013)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Bazan, A., Nowicki, P. & Pietrzak, R. Removal of NO2 by carbonaceous adsorbents obtained from residue after supercritical extraction of marigold. Adsorption 22, 465–471 (2016). https://doi.org/10.1007/s10450-015-9709-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10450-015-9709-1