Abstract

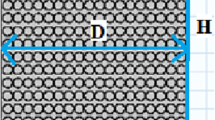

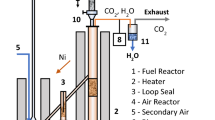

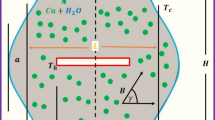

Radial flow reactors (RFR) are used in thermal swing adsorption (TSA) processes for gas prepurification. The aim of this work is to show the validity of the discrete element method (DEM) to simulate the effect of thermal expansion and contraction cycles occurring in such processes on the packed bed of RFR reactors. Both mono-layered and bi-layered packed beds of adsorbents are investigated. A DEM-based model of a full-scale size unit was developed, the parameters of which were calibrated by means of particle-scale experimental measurements and simple auxiliary DEM simulations. The DEM-based model used is isothermal and the thermal expansion and contraction phenomena are modelled through the displacement of the inner and outer walls of the computational domain. First, the accuracy of this model is assessed using analytical values of the static wall pressure (i.e. with no wall motion) as well as experimental measurements of the dynamic wall pressure (i.e. with wall motion) of a bi-layered bed. Next, simulation results for a few process cycles in the case of a bi-layered packed bed indicates that little mixing occurs at the interface between the two types of adsorbents. To our knowledge, this is the first time that simulation is used to investigate the behavior of the packed bed of a RFR in a TSA process. The results obtained with the proposed model show that the DEM is a valuable tool for the investigation of such slow dynamical processes, provided a careful calibration is done.

Similar content being viewed by others

References

Ackley, M.W., Celik, C.E., Nowobilski, J.J., Schneider, J.S.: Radial flow reactor. US 8,101,133 B2, 24 Jan (2012)

Akseli, I., Cetinkaya, C.: Drug tablet thickness estimations using air-coupled acoustics. Int. J. Pharm. 351(1–2), 165–173 (2008)

Balevicius, R., Sielamowicz, I., Mroz, Z., Kacianauskas, R.: Investigation of wall stress and outflow rate in a flat-bottomed bin: a comparison of the DEM model results with the experimental measurements. Powder Technol. 214(3), 322–336 (2011)

Bertrand, F., Gange, T., Desaulniers, E., Vidal, D., Hayes, R.E.: Simulation of the consolidation of paper coating structures: probabilistic versus deterministic models. Comput. Chem. Eng. 28(12), 2595–2604 (2004)

Bertrand, F., Leclaire, L.A., Levecque, G.: DEM-based models for the mixing of granular materials. Chem. Eng. Sci. 60, 2517–2531 (2005)

Celik, C.E., Ackley, M.W.: Radial bed vessels having uniform flow distribution. US 8,313,561 B2, 20 Nov (2012)

Cetinkaya, C.: Accoustic Measurement of Young’s Modulus and Poisson’s Ratio for Adsorbents Beads. In: unpublished Praxair Project Progress Report (375–35322), Clarkson University. (2009)

Couroyer, C., Ning, Z., Ghadiri, M., Brunard, N., Kolenda, F., Bortzmeyer, D., Laval, P.: Breakage of macroporous alumina beads under compressive loading: simulation and experimental validation. Powder Technol. 105, 57–65 (1999)

Cundall, P.A., Strack, O.D.L.: Discrete numerical model for granular assemblies. Geotechnique 29(1), 47–65 (1979)

Einstein, A.: Motion of suspended particles on the kinetic theory. Ann. Phys. 17(3), 549–560 (1905)

Fraige, F.Y., Langston, P.A.: Integration schemes and damping algorithms in distinct element models. Adv. Powder Technol. 15(2), 227–245 (2004)

Goda, T.J., Ebert, F.: Three-dimensional discrete element simulations in hoppers and silos. Powder Technol. 158(1–3), 58–68 (2005)

Gonzalez-Montellano, C., Gallego, E., Ramirez-Gomez, A., Ayuga, F.: Three dimensional discrete element models for simulating the filling and emptying of silos: analysis of numerical results. Comput. Chem. Eng. 40, 22–32 (2012a)

Gonzalez-Montellano, C., Ramirez, A., Fuentes, J.M., Ayuga, F.: Numerical effects derived from en masse filling of agricultural silos in DEM simulations. Comput. Electron. Agric. 81, 113–123 (2012b)

Gonzalez-Montellano, C., Ramirez, A., Gallego, E., Ayuga, F.: Validation and experimental calibration of 3D discrete element models for the simulation of the discharge flow in silos. Chem. Eng. Sci. 66(21), 5116–5126 (2011)

Hartl, J., Ooi, J.Y.: Experiments and simulations of direct shear tests: porosity, contact friction and bulk friction. Granul. Matter 10(4), 263–271 (2008)

Heggs, P.J., Ellis, D.I., Ismail, M.S.: Modelling of fluid-flow distributions in annular packed beds. Gas Sep. Purif. 8(4), 257–264 (1994)

Heggs, P.J., Ellis, D.I., Ismail, M.S.: Evaluation of pressure profiles and overall pressure drop for flow through annular packed bed configurations. Gas Sep. Purif. 9(3), 171 (1995a)

Heggs, P.J., Ellis, D.I., Ismail, M.S.: Prediction of flow distributions and pressure changes in multi-layered annular packed beds. Gas Sep. Purif. 9(4), 243 (1995b)

Hidano, T., Nakamura, M., Kawai, M.: Pre-purification unit of cryogenic air separation unit, hydrocarbon adsorbent, and method of pre-treating feed air. US 7,931,736 B2, 26 Apr (2011)

Johnson, K.L.: Contact Mechanics. Cambridge University Press, Cambridge (1985)

Kalbassi, M.A., Golden, T.C.: Purification of gases using solid adsorbents. US 5,855,650, 5 Jan (1999)

Kareeri, A.A., Zughbi, H.D., Al-Ali, H.H.: Simulation of flow distribution in radial flow reactors. Ind. Eng. Chem. Res. 45, 2862–2874 (2006)

Ketterhagen, W.R., Curtis, J.S., Wassgren, C.R., Hancock, B.C.: Predicting the flow mode from hoppers using the discrete element method. Powder Technol. 195(1), 1–10 (2009)

Ko, D., Kim, M., Moon, I., Choi, D.: Analysis of purge gas temperature in cyclic TSA process. Chem. Eng. Sci. 57(1), 179–195 (2002)

Kumar, R., Deng, S.: Trace carbon monoxide and hydrogen conversion prior to cryogenic distillation of air. Adsorption 12(5–6), 361–373 (2006)

Kumar, R., Dissinger, G.R.: Nonequilibrium, nonisothermal desorption of single adsorbate by purge. Ind. Eng. Chem. Process Des. Dev. 25(2), 456–464 (1986)

Kumar, R., Huggahalli, M., Bülow, M.: Thermal swing adsorption process. US 6,432,171 B1, 13 Aug (2002)

Landry, J.W., Grest, G.S., Plimpton, S.J.: Discrete element simulations of stress distributions in silos: crossover from two to three dimensions. Powder Technol. 139(3), 233–239 (2004)

Landry, J.W., Grest, G.S., Silbert, L.E., Plimpton, S.J.: Confined granular packings: structure, stress, and forces. Phys. Rev. E (Stat. Nonlinear Soft Matter Phys. 67(4), 41301–41303 (2003)

Leclaire, L.-A.: Parallélisation de la méthode des éléments discrets appliquée aux écoulements granulaires (Parallelization of the discrete element method applied to granular flows). Mémoire de maîtrise (Ecole polytechnique de Montréal) (2004)

Lemieux, M., Bertrand, F., Chaouki, J., Gosselin, P.: Comparative study of the mixing of free-flowing particles in a V-blender and a bin-blender. Chem. Eng. Sci. 62(6), 1783–1802 (2007)

Li, C., Cetinkaya, C.: Frequency domain thickness measurement approach for microscale multilayered structures. IEEE Trans. Instrum. Meas. 55(1), 206–211 (2006)

Li, Y., Xu, Y., Thornton, C.: A comparison of discrete element simulations and experiments for ‘sandpiles’ composed of spherical particles. Powder Technol. 160(3), 219–228 (2005)

Libal, K., Fierlbeck, W., Von Gemmingen, U.: Adsorption reactor solid cage walls—for minimal erosion of contained solids during adaptation to temp. Change by inherent expansion of the walls. US 5,827,485, 27 Oct (1998)

Lobanov, E.L., Skipin, Y.A.: Increasing the operating efficiency of radial reactors in reforming. Chem. Technol. Fuels Oils 22(5–6), 275–278 (1986)

Masson, S., Martinez, J.: Effect of particle mechanical properties on silo flow and stresses from distinct element simulations. Powder Technol. 109(1–3), 164–178 (2000)

Nedderman, R.M.: Statics and Kinematics of Granular Materials, Digitally printed 1st pbk edn. Cambridge University Press, Cambridge (2005)

Ponzi, P.R., Kaye, L.A.: Effect of flow maldistribution on conversion and selectivity in radial flow fixed-bed reactors. AIChE J. 25(1), 100–108 (1979)

Rapaport, D.C.: Radial and axial segregation of granular matter in a rotating cylinder: a simulation study. Phys. Rev. E (Stat. Nonlinear Soft Matter Phys.) 75(3), 31301 (2007)

Ruthven, D.M.: Principles of Adsorption and Adsorption Processes. Wiley, New York (1984)

Schneider, J.S., Smolarek, J., Ackley, M.W., Nowobilski, J.J.: Assembly and method for loading particles into a vessel. US 5,836,362-A, 17 Nov (1998)

Seader, J.D., Henley, E.J.: Separation Process Principles. Wiley, New York (1998)

Sondergaard, R., Chaney, K., Brennen, C.E.: Measurements of solid spheres bouncing off flat plates. J. Appl. Mech. Trans. ASME 57(3), 694–699 (1990)

Sudah, O.S., Arratia, P.E., Alexander, A., Muzzio, F.J.: Simulation and experiments of mixing and segregation in a tote blender. AIChE J. 51(3), 836–844 (2005)

Tsuji, Y., Tanaka, T., Ishida, T.: Lagrangian numerical simulation of plug flow of cohesionless particles in a horizontal pipe. Powder Technol. 71(3), 239–250 (1992)

Zhou, Y.C., Wright, B.D., Yang, R.Y., Xu, B.H., Yu, A.B.: Rolling friction in the dynamic simulation of sandpile formation. Phys. A 269(2), 536–553 (1999)

Zhou, Y.C., Xu, B.H., Yu, A.B., Zulli, P.: Numerical investigation of the angle of repose of monosized spheres. Phys. Rev. E (Stat. Nonlinear Soft Matter Phys.) 64(2 I), 213011–213018 (2001)

Zhou, Y.C., Xu, B.H., Yu, A.B., Zulli, P.: An experimental and numerical study of the angle of repose of coarse spheres. Powder Technol. 125(1), 45–54 (2002)

Acknowledgments

The financial support of the Natural Sciences and Engineering Research Council of Canada (NSERC) and PRAXAIR Inc. is gratefully acknowledged. All simulations were made possible thanks to the computational resources of Compute Canada.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Dubé, O., Ackley, M., Celik, C. et al. Discrete element simulation of the dynamics of adsorbents in a radial flow reactor used for gas prepurification. Adsorption 20, 91–107 (2014). https://doi.org/10.1007/s10450-013-9552-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10450-013-9552-1