Abstract

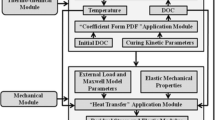

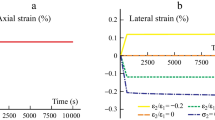

In this paper, two kinds of transient models, the viscoelastic model and the linear elastic model, are established to analyze the curing deformation of the thermosetting resin composites, and are calculated by COMSOL Multiphysics software. The two models consider the complicated coupling between physical and chemical changes during curing process of the composites and the time-variant characteristic of material performance parameters. Subsequently, the two proposed models are implemented respectively in a three-dimensional composite laminate structure, and a simple and convenient method of local coordinate system is used to calculate the development of residual stresses, curing shrinkage and curing deformation for the composite laminate. Researches show that the temperature, degree of curing (DOC) and residual stresses during curing process are consistent with the study in literature, so the curing shrinkage and curing deformation obtained on these basis have a certain referential value. Compared the differences between the two numerical results, it indicates that the residual stress and deformation calculated by the viscoelastic model are more close to the reference value than the linear elastic model.

Similar content being viewed by others

References

Bogetti, T.A., Gillespie, J.W.: Process-induced stress and deformation in thick-section thermoset composite laminates. J. Compos. Mater. 26(5), 626–660 (1992)

Griffin, O.H.: Three-dimensional curing stresses in symmetric cross-ply laminates with temperature-dependent properties. J. Compos. Mater. 17(5), 449–463 (1983)

Hahn, H.T.: Residual stresses in polymer matrix composite laminates. J. Compos. Mater. 10(4), 266–277 (1976)

Costa, V., Sousa, A.: Modeling of flow and thermo-kinetics during the cure of thick laminated composites. Int. J. Therm. Sci. 42(1), 15–22 (2003)

Shin, D.D., Hahn, H.T.: Compaction of thick composites: simulation and experiment. Polym. Compos. 25(1), 49–59 (2004)

Svanberg, J.M., Holmberg, J.A.: Prediction of the shape distortions part I: FE implementation of a path dependent constitutive model. Compos A: Appl Sci Manuf. 35(6), 711–721 (2004)

Adolf, D.B., Chambers, R.S.: A thermodynamically consistent, nonlinear viscoelastic approach for modelling thermosets during cure. J. Rheol. 51(1), 23–50 (2007)

Ganapathi, A.S., Joshi, S.C., Chen, Z.: Simulation of Bleeder flow and curing of thick composites with pressure and temperature dependent properties. Simul Model Pract Theory. 32(1), 64–82 (2013)

Abdelal, G.F., Robotham, A., Cantwell, W.: Autoclave cure simulation of composites structures applying implicit and explicit FE techniques. Int. J. Mech. Mater. Des. X9x(1), 55–63 (2013)

Vautard, F., Ozcan, S., Poland, L.: Influence of thermal history on the mechanical properties of carbon fiber-acrylate composites cured by electron beam and thermal processes. Compos A: Appl Sci Manuf. X45X(2), 162–172 (2013)

Curiel, T., Fernlund, G.: Deformation and stress build-up in bi-material beam specimens with a curing FM 300 adhesive interlayer. Compos A: Appl Sci Manuf. 39(2), 252–261 (2008)

Wisnom, M.R., Gigliotti, M., Ersoy, N., Campbell, M., Potter, K.D.: Mechanisms generating residual stresses and distortion during manufacture of polymer-matrix composite structures. Compos A: Appl Sci Manuf. X37(4), 522–529 (2006)

Ruiz, E., Trochu, F.: Numerical analysis of cure temperature and internal residual stresses in thin and thick RTM parts. Compos A: Appl Sci Manuf. 36x(6), 806–826 (2005)

Jansen, K.M.B., De Vreugd, J., Ernst, L.J.: Analytical estimate for curing-induced stress and warpage in coating layers. J. Appl. Polym. Sci. 126(5), 1623–1630 (2012)

Tavakol, B., Roozbehjavan, P., Ahmed, A., Das, R., Joven, R., Koushyar, H.: Prediction of residual stresses and distortion in carbon fiber-epoxy composite parts due to curing process using finite element. J. Appl. Polym. Sci. 128(2), 941–950 (2013)

White, S.R., Hahn, H.T.: Process modeling of composite materials: residual stress development during cure. Part II. Experimental validation. J. Compos. Mater. 26(16), 2423–2453 (1992)

Prasatya, R., McKenna, G.B., Simon, S.L.: A viscoelastic model for predicting isotropic residual stresses in thermosetting materials: effects of processing parameters. J. Compos. Mater. 35(10), 826–849 (2001)

Khoun, L., Hubert, P.: Investigation of the dimensional stability of carbon epoxy cylinders manufactured by resin transfer moulding. Compos A: Appl Sci Manuf. 41(1), 116–124 (2013)

Toudeshky, H.H., Sadighi, M., Vojdani, A.: Effects of curing thermal residual stresses on fatigue crack propagation of aluminum plates repaired by FML patches. Compos. Struct. 100(6), 154–162 (2013)

Wang, X.X., Zhao, Y.R., Su, H., Jia, Y.X.: Curing process-induced internal stress and deformation of fiber reinforced resin matrix composites: numerical comparison between elastic and viscoelastic models. Polym. Polym. Compos. 24(2), 155–160 (2016)

Stango, R.J., Wang, S.S.: Process-induced residual thermal stresses in advanced fiber-reinforced composite laminates. J. Manuf. Sci. Eng. 106(1), 48–54 (1984)

Shokrieh, M.M., Kamali, S.M.: Theoretical and experimental studies on residual stresses in laminated polymer composites. J. Compos. Mater. 39(24), 2213–2225 (2005)

KimYK, W.S.R.: Stress relaxation behavior of 3501-6 epoxy resin during cure. Polym. Eng. Sci. 36(23), 2852–2862 (1996)

O’Brien, D.J., Mather, P.T., White, S.R.: Viscoelastic properties of an epoxy resin during cure. J. Compos. Mater. 35(10), 883–904 (2001)

Patham, B.: Multiphysics simulations of cure residual stresses and springback in a thermoset resin using a viscoelastic model with cure-temperature-time superposition. J. Appl. Polym. Sci. 129(3), 983–998 (2013)

Taylor, R.L., Pister, K.S., Goudreau, G.L.: Thermo-mechanical analysis of viscoelastic solids. Int. J. Numer. Methods Eng. 2(1), 45–59 (1970)

Kim, Y.K., White, S.R.: Process-Induced stress relaxation analysis of AS4/3501-6 laminate. J. Reinf. Plast. Compos. 26(1), 2–16 (1997)

Hong, L.C., Hwang, S.J.: Study of warpage due to P-V-T-C relation of EMC in IC packaging. IEEE Trans Compon Packag Technol. 27, 291–295 (2004)

Salla, J.M., Ramis, X.: Comparative study of the cure kinetics of an unsaturated polyester resin using different procedures. Polym. Eng. Sci. 36(6), 835–850 (1996)

Johnston, A., Vaziri, R., Poursartip, A.: A plane strain model for process-induced deformation of laminated composite structures. J. Compos. Mater. 35(16), 1435–1469 (2001)

Kim, Y.K., White, S.R.: Viscoelastic analysis of processing-induced residual stresses in thick composite laminates. Mech. Compos. Mater. Struct. 4(4), 361–387 (1997)

White, S.R., Kim, Y.K.: Process-induced residual stress analysis of AS4/3501-6 composite material. Mech Compos Mater Struct. 5(2), 153–186 (1998)

Ma, Y.R., He, J.L., Li, D., Tan, Y., Xu, L.: Numerical simulation of curing deformation of resin matrix composite curved structure. Acta Materiae Compositae Sinica. 32(3), 874–880 (2015)

Tavman, I., Akinci, H.: Transverse thermal conductivity of fiber reinforced polymer composites. Int Commun Heat Mass. 27(2), 253–261 (2000)

Acknowledgements

The author would like to thank “Jing Hou Xin” research group for many fruitful discussions. This work is supported by the National Natural Science Foundation of China (Grant No. 11664023).

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

This appendix presents micromechanical homogenization equations which used to determine the overall composite properties of unidirectional lamina. Noted that subscripts f and r represent fiber and resin, respectively. The thermo-physical properties of the composites, including the density, ρ, the specific heat capacity, C p , and the longitudinal thermal conductivity, k L , (x -direction in Eq. (1)), can be respectively calculated by the following rule of mixtures [33]:

The transverse thermal conductivity of the composites, k T , (y and z -direction in Eq. (1)) can be calculated based on the E-S model [34]. It is given as:

in which:

where a and b are the axial lengths of the elliptic section of the fiber along the y -axis and z -axis, respectively. In this paper, the cross section of the fiber is round, so a is equal to b, i.e.μ = 1.

Self-consistent micromechanics homogenization equations [32] used to determine the composite properties are listed in this appendix. Subscripts 1, 2 and 3 represent the principal directions of unidirectional lamina. The Young’s modulus of the composites in the longitudinal direction of the fiber is expressed as:

in which:

where E 1f and E 2f are the Young’s modulus of the fiber in the longitudinal direction and transverse direction; E r is the Young’s modulus of the resin; G r is the shear modulus of the resin; υ 12f and υ 23f are the in-plane Poisson’s ratio and transverse Poisson’s ratio of the fiber; υ r is the Poisson’s ratio of the resin; K f and K r are the bulk modulus of the fiber and resin, respectively.

The in-plane shear modulus of the composites is expressed as:

The out-of-plane shear modulus of the composites is expressed as:

where G 12f and G 23f are the in-plane shear modulus and out-of-plane shear modulus of the fiber, respectively.

The plane strain bulk modulus of the composites is expressed as:

The Young’s modulus of the composites in the transverse direction of the fiber is expressed as:

The in-plane Poisson’s ratio of the composites is expressed as:

The out-of-plane Poisson’s ratio of the composites is expressed as:

The longitudinal CTE of the composites is expressed as:

The transverse CTE of the composites is expressed as:

Rights and permissions

About this article

Cite this article

Li, D., Li, X. & Dai, J. Process Modelling of Curing Process-Induced Internal Stress and Deformation of Composite Laminate Structure with Elastic and Viscoelastic Models. Appl Compos Mater 25, 527–544 (2018). https://doi.org/10.1007/s10443-017-9633-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-017-9633-5