Abstract

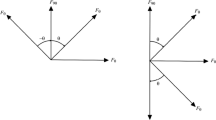

The in-plane shear and compressive properties of unidirectional (UD) HTS40/977-2 carbon fibre-toughened resin (CF/TR) laminates are investigated. Scanning Electron microscopy (SEM) and optical microscopy are used to reveal the failure mechanisms developed during compression. It is found that damage initiates by fibre microbuckling (a fibre instability failure mode) which then is followed by yielding of the matrix to form a fibre kink band zone that leads to final fracture. Analytical models are briefly reviewed and a graphical method, based on the shear response of the composite system, is described in order to estimate the UD compressive strength. Predictions for the HTS40/977-2 system are compared to experimental measurements and to data of five other unidirectional carbon fibre reinforced polymer (CFRP) composites that are currently used in aerospace and other structural applications. It is shown that the estimated values are in a good agreement with the measured results.

Similar content being viewed by others

References

Soutis, C.: Fibre reinforced composites in aircraft construction. Prog. Aerosp. Sci. 41(2), 143–151 (2005)

Cano, R.J., Dow, M.B.: Properties of five toughened matrix composite materials. NASA technical paper 3254. National aeronautics and space administration (NASA) Langley research centre, USA (1992).

Smith, D.L., Dow, M.B.: Properties of three graphite/toughened resin composites. NASA technical paper 3102. NASA Langley research centre, USA (1991)

Dow, M.B., Smith, D.L.: Properties of two composite materials made of toughened epoxy resin and high strain graphite fibre. NASA technical paper 2826. NASA Langley research centre, USA (1988)

Hahn, H.T., Williams, J.G.: Compression failure mechanism in unidirectional composites. In: Whitney, J.M. (ed.) Composite materials: testing and design (seventh conference) ASTM STP 893, pp. 115–139. ASTM, Philadelphia (1986)

Janke, C.J., Dorsey, G.F., Havens, S.J., Lopata, V.J.: Toughened epoxy system and a method thereof. United States Patent 5726216. US patents, USA (1998)

Bagheri, R., Pearson, R.A.: Role of particle cavitation in rubber-toughened epoxies: II. Inter-particle distance. Polymer 41, 269–276 (2000)

Lu, R., Plummer, C.J.G., Cantwell, W.J., Kausch, H.H.: Toughening mechanisms in modified epoxy resins with different crosslink densities. Polym. Bull. 37, 399–406 (1996)

Pearson, R.A., Yee, A.F.: Toughening mechanisms in thermoplastic-modified epoxies: I. Modification using poly(phenylene oxide). Polymer 34, 3658–3670 (1993)

Curtis, P.T.: CRAG test methods for the measurement of the engineering properties of fibre reinforced plastics. RAE Technical Report 85099. Royal Aircraft Establishment, Farnborough UK (1985)

Sabo, J., Strait, L.H., Strauch, E.C., Koudela, K.L., Giannetti, W.B.: Processing and characterization of thick laminated composites. In: Composites Materials, Mechanics and Processing, Proceedings of the American Society for composites, pp. 574–586. CRC Press, USA (1994)

Pethrick, R.A., Hollins, E.A., McEwan, I., MacKinnon, A.J., Hayward, D., Cannon, L.A., Jenkins, S.D., McGrail, P.T.: Dielectric, mechanical and structural, and water absorption properties of a Thermoplastic-modified epoxy resin: Poly(ether sulfone)−Amine cured epoxy resin. Macromolecules 29(15), 5208–5214 (1996)

McGrail, P.T.: Polyaromatics. Polym. Int. 41, 103–121 (1996)

Di Pasquale, G., Motta, O., Recca, A.: New high-performance thermoplastic toughened epoxy thermosets. Polymer 38(17), 4345–4348 (1997)

Akay, M., Cracknell, J.G.: Epoxy resin-polyethersulphone blends. J. Appl. Polym. Sci. 52(5), 663–688 (1994)

Moon, C.R., Bang, B.R., Choi, W.J., Kang, G.H., Park, S.Y.: A technique for determining fiber content in FRP by thermogravimetric analyzer. Polym. Test. 24(3), 376–380 (2005)

Lee, J., Soutis, C.: A study on the compressive strength of thick carbon fibre–epoxy laminates. Compos. Sci. Technol. 67, 2015–2026 (2007)

Lee, J.H.: Compressive behaviour of composite laminates before and after low velocity impact. PhD thesis. University of London (2003)

Cheremisinoff, N.P.: Advanced polymer processing operations. William Andrew, USA (1998)

Berbinau, P., Soutis, C., Guz, I.A.: Compressive failure of 0° unidirectional carbon-fibre-reinforced plastic (CFRP) laminates by fibre microbuckling. Compos. Sci. Technol. 59, 1451–1455 (1999)

Yurgartis, S.W.: Measurement of small angle fiber misalignments in continuous fiber composites. Compos. Sci. Technol. 30, 279–293 (1987)

Budiansky, B.: Micromechanics. Comput. Struct. 16(1), 3–12 (1983)

Rosen, B.W.: Mechanics of composite strengthening. In: Fibre composite materials, Proceedings of the American Society for metals, pp. 574–586. American society for metals USA (1965)

Soutis, C., Curtis, P.T.: A method for predicting the fracture toughness of CFRP laminates failing by fibre microbuckling. Compos. A 31(7), 733–740 (2000)

Soutis, C., Smith, F.C., Matthews, F.L.: Predicting the compressive engineering performance of carbon fibre-reinforced plastics. Compos. A 31(6), 531–536 (2000)

Hu, F.Z., Soutis, C., Edge, E.C.: Interlaminar stresses in composite laminates with a circular hole. Compos. Struct. 37(2), 223–232 (1997)

Soutis, C.: Compressive strength of unidirectional composites: measurement and prediction. ASTM-STP1242 13,168–176 (1997)

Jumahat, A., Soutis, C., Jones, F.R., Hodzic, A.: Fracture mechanisms and failure analysis of carbon fibre/toughened epoxy composites subjected to compressive loading. Compos. Struct. 92(2), 295–305 (2010)

Soutis, C.: Compression testing of pultruded carbon fiber-epoxy cylindrical rods. J. Mater. Sci. 34, 3441–3446 (2000)

Madan, R.C.: Composite transport wing technology development. NASA Contractor Report 178409. NASA Langley Research Centre USA (1988)

Guz, I.A., Soutis, C.: Predicting fracture of layered composites caused by internal instability. Compos. A 32(9), 1243–1253 (2001)

Guz, I.A., Soutis, C.: Compressive fracture of non-linear composites undergoing large deformations. Int. J. Solids Struct. 38(21), 3759–3770 (2001)

Diaz Valdes, S.H., Soutis, C.: Real-time non-destructive evaluation of fibre composite laminates using low-frequency Lamb waves. J. Accoust. Soc. America. 111(5), 2026–2033 (2002)

Diamanti, K., Soutis, C., Hodgkinson, J.M.: Piezoelectric transducer arrangement for the inspection of large composite structures. Compos. A 38(4), 1121–1130 (2007)

Acknowledgements

The authors wish to acknowledge the Universiti Teknologi MARA and the Ministry of Higher Education Malaysia for a PhD scholarship. Also, the authors wish to thank the Cytec Engineered Materials Ltd. for financial support and the supply of materials. The authors wish to express their gratitude to the University of Sheffield Composites Group members, especially Prof. F R Jones, Dr S Hayes, Dr P Bailey, A D Lafferty, T Swait, AV Ho and V Nekouie, for many helpful technical discussions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jumahat, A., Soutis, C. & Hodzic, A. A Graphical Method Predicting the Compressive Strength of Toughened Unidirectional Composite Laminates. Appl Compos Mater 18, 65–83 (2011). https://doi.org/10.1007/s10443-010-9149-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-010-9149-8