Abstract

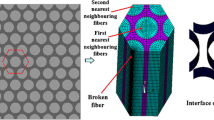

Thermal residual stress is one of the major factors affecting composite mechanical performance. In this paper, a 3-D FEA technique was utilized to analyze the thermal residual stress distribution in Carbon fiber/PPESK composite. Parabolic failure criterion was used to predict composite potential failure zone. Results indicate that, thermal residual stress distributions in different parts of the composite are different. At composite free end zone, the maximum thermal residual stress is located at fiber surface; in composite inner zone, the maximum stress is located in the matrix; at composite defect zone, stress concentration is located at defect surface. Thermal residual stress at composite free end zone will lead to fiber–matrix interfacial de-bonding. Thermal residual stress concentration at composite defect zone will decrease composite mechanical performance.

Similar content being viewed by others

References

Diaz, J., Rubio, L.: Developments to manufacture structural aeronautical parts in carbon fiber reinforced thermoplastic materials. J. Mater. Process. Technol. 143–144, 342–346 (2003). doi:10.1016/S0924-0136(03)00450-3

Dubé, M., Hubert, P., Yousefpour, A., et al.: Resistance welding of thermoplastic composites skin/stringer joints. Compos. Part A 38, 2541–2552 (2007). doi:10.1016/j.compositesa.2007.07.014

Rosso, P., Varadi, K.: FE macro/micro analysis of thermal residual stresses and failure behavior under transverse tensile load of VE/CF–fiber bundle composites. Compos. Sci. Technol. 66, 3241–3253 (2006). doi:10.1016/j.compscitech.2005.07.004

Fiedler, B., Hojo, M., Ochiai, S.: The influence of thermal residual stresses on the transverse strength of CFRP using FEM. Compos. Part A 33, 1323–1326 (2002). doi:10.1016/S1359-835X(02)00169-0

Fiedler, B., Hojo, M., Ochiai, S., Schulte, K., Ochi, M.: Finite-element modeling of initial matrix failure in CFRP under static transverse tensile load. Compos. Sci. Technol. 61, 95–105 (2001). doi:10.1016/S0266-3538(00)00198-6

Parlevliet, P.P., Bersee, H.E.N., Beukers, A.: Residual stresses in thermoplastic composites—a study of the literature—Part I: Formation of residual stresses. Compos. Part A 37, 1847–1857 (2006). doi:10.1016/j.compositesa.2005.12.025

Parlevliet, P.P., Bersee, H.E.N., Beukers, A.: Residual stresses in thermoplastic composites—a study of the literature—Part II: Experimental techniques. Compos. Part A 38, 651–665 (2007)

Parlevliet, P.P., Bersee, H.E.N., Beukers, A.: Residual stresses in thermoplastic composites—a study of the literature. Part III: Effects of thermal residual stresses. Compos. Part A 38, 1581–1596 (2007). doi:10.1016/j.compositesa.2006.12.005

Abedian, A., Szyszkowski, W.: Influence of the free surface on the thermal residual stresses in unidirectional composites. Compos. Part A 28, 573–579 (1997)

Nickerson, S., Mayes, J.S., Welsh, J.S.: Multi-continuum analysis of thermally induced matrix cracking. Eng. Fract. Mech. 72(12), 1993–2008 (2005)

Fiedler, B., Schulte, K.: Photo-elastic analysis of fibre-reinforced model composite materials. Compos. Sci. Technol. 57(8), 859–867 (1997)

Lu, C., Chen, P., Yu, Q., et al.: Interfacial adhesion of plasma treated carbon fiber/Poly (phthalazinone ether sulfone ketone) composite. J. Appl. Polym. Sci. 106, 1733–1741 (2007)

Chen, P., Lu, C., Yu, Q.: Influence of fiber wettability on the interfacial adhesion of continuous fiber reinforced PPESK composite. J. Appl. Polym. Sci. 102, 2544–2551 (2006)

Zhao, Q.: Advanced composite manual. Mechanical Industry Press, Beijing (2008)

Tsai, J.L., Chi, Y.K.: Investigating thermal residual stress effect on mechanical behaviors of fiber composites with different fiber arrays. Compos. Part B 39, 714–721 (2008)

Tschoegl, N.W.: Failure surfaces in principal stress spaces. J. Polymer Sci. Part C Polym. symp. 32, 239–267 (1971)

Theocaris, P.S., Philippidis, T.P.: The paraboloidal failure surface of initially anisotropic elastic solids. J. Reinf. Plast. Compos. 6, 378–395 (1987)

Gourichon, B., Binetruy, C., Krawczak, P.: A new numerical procedure to predict dynamic void content in liquid composite molding. Compos. Part A 37(11), 1961–1969 (2006)

Ruiz, E., Achim, V., Soukane, S., et al.: Optimization of injection flow rate to minimize micro/macro-voids formation in resin transfer molded composites. Compos. Sci. Technol. 66(3–4), 475–486 (2006)

Hu, J.L., Liu, Y., Shao, X.M.: Study on void formation in multi-layer woven fabrics. Compos. Part A 35(5), 595–603 (2004)

Turner, D.Z., Hjelmstad, K.D., LaFave, J.M.: Three-dimensional flow visualization experiment of an RTM injection for a GFRP cuff mold. Compos Struct 76(4), 352–361 (2006)

Kang, M.K., Lee, W.I.H., Hahn, T.: Formation of microvoids during resin-transfer molding process. Compos. Part A 60(12–13), 2427–2434 (2000)

Varna, J., Joffe, R., Berglund, L.A., et al.: Effect of voids on failure mechanisms in RTM laminates. Compos. Sci. Technol. 53(2), 241–249 (1995)

Acknowledgements

This experiment is supported by National Defense 11th 5 year program Foundational Research Program (No. A352060215), Program for Liaoning Excellent Talents in University (No. 2005RC-14). The author would like to acknowledge the valuable help given by the organizations.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lu, C., Chen, P., Yu, Q. et al. Thermal Residual Stress Distribution in Carbon Fiber/Novel Thermal Plastic Composite. Appl Compos Mater 15, 157–169 (2008). https://doi.org/10.1007/s10443-008-9064-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-008-9064-4