Abstract

A crystal plasticity constitutive model of high-entropy alloys (HEAs) coupled with damage evolution equation at high temperature is developed. To simulate the degraded load-carrying capacity of HEAs caused by microdefects, a phenomenological damage evolution equation is proposed based on the compression experiments at different temperatures. The established model is used to simulate the stress softening phenomenon of polycrystalline AlCrCuFeNi-based HEAs, which is highly dependent on the strain rate and temperature. Compared with the experimental data, the proposed model is able to accurately describe the stress-strain relationship of HEAs.

摘要

本文建立了高熵合金在高温下耦合损伤的晶体塑性本构模型. 为了模拟微缺陷引起的高熵合金承载力下降的现象, 提出一个基于压缩试验数据的唯象损伤演化方程. 开发的本构模型被用于模拟AlCrCuFeNi基的多晶高熵合金的应力软化现象, 且可以描述高熵合金变形的温度和率相关性. 将模拟结果与试验数据对比, 该模型能够准确描述高熵合金的应力-应变关系.

Similar content being viewed by others

References

S. Liu, M. C. Gao, P. K. Liaw, and Y. Zhang, Microstructures and mechanical properties of Al CrFeNiTi0.25 alloys, J. Alloys Compd. 619, 610 (2015).

Y. Fu, J. Li, H. Luo, C. Du, and X. Li, Recent advances on environmental corrosion behavior and mechanism of high-entropy alloys, J. Mater. Sci. Tech. 80, 217 (2021).

X. W. Qiu, Y. P. Zhang, L. He, and C. Liu, Microstructure and corrosion resistance of AlCrFeCuCo high entropy alloy, J. Alloys Compd. 549, 195 (2013).

C. Y. He, X. L. Qiu, D. M. Yu, S. S. Zhao, H. X. Guo, G. Liu, and X. H. Gao, Greatly enhanced solar absorption via high entropy ceramic AlCrTaTiZrN based solar selective absorber coatings, J. Materiomics 7, 460 (2021).

Y. Lu, Y. Dong, S. Guo, L. Jiang, H. Kang, T. Wang, B. Wen, Z. Wang, J. Jie, Z. Cao, H. Ruan, and T. Li, A promising new class of high-temperature alloys: Eutectic high-entropy alloys, Sci. Rep. 4, 6200 (2015).

K. M. Youssef, A. J. Zaddach, C. Niu, D. L. Irving, and C. C. Koch, A novel low-density, high-hardness, high-entropy alloy with close-packed single-phase nanocrystalline structures, Mater. Res. Lett. 3, 95 (2015).

N. Nayan, G. Singh, S. V. S. N. Murty, A. K. Jha, B. Pant, K. M. George, and U. Ramamurty, Hot deformation behaviour and microstructure control in AlCrCuNiFeCo high entropy alloy, Intermetallics 55, 145 (2014).

S. Samal, M. R. Rahul, R. S. Kottada, and G. Phanikumar, Hot deformation behaviour and processing map of Co−Cu−Fe−Ni−Ti eutectic high entropy alloy, Mater. Sci. Eng.-A 664, 227 (2016).

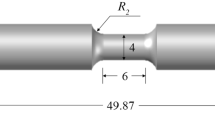

X. Wang, Y. Zhang, and X. Ma, High temperature deformation and dynamic recrystallization behavior of AlCrCuFeNi high entropy alloy, Mater. Sci. Eng.-A 778, 139077 (2020).

M. R. Rahul, S. Samal, S. Venugopal, and G. Phanikumar, Experimental and finite element simulation studies on hot deformation behaviour of AlCoCrFeNi2.1 eutectic high entropy alloy, J. Alloys Compd. 749, 1115 (2018).

O. T. Bruhns, Large deformation plasticity, Acta Mech. Sin. 36, 472 (2020).

X. Feng, Y. P. Yao, R. N. Li, Z. Wan, and X. Dai, Loading-unloading judgement for advanced plastic UH model, Acta Mech. Sin. 36, 827 (2020).

L. Wang, J. Xu, J. Wang, and B. L. Karihaloo, Nonlocal thermo-elastic constitutive relation of fibre-reinforced composites, Acta Mech. Sin. 36, 176 (2020).

Y. Tong, J. C. Qiao, and Y. Yao, The constitutive model and threshold stress for characterizing the deformation mechanism of Al0.3CoCr−FeNi high entropy alloy, Mater. Sci. Eng.-A 730, 137 (2018).

T. J. Gao, D. Zhao, T. W. Zhang, T. Jin, S. G. Ma, and Z. H. Wang, Strain-rate-sensitive mechanical response, twinning, and texture features of NiCoCrFe high-entropy alloy: Experiments, multi-level crystal plasticity and artificial neural networks modeling, J. Alloys Compd. 845, 155911 (2020).

R. Sonkusare, R. Jain, K. Biswas, V. Parameswaran, and N. P. Gurao, High strain rate compression behaviour of single phase CoCuFeMnNi high entropy alloy, J. Alloys Compd. 823, 153763 (2020).

X. He, L. Liu, T. Zeng, and Y. Yao, Micromechanical modeling of work hardening for coupling microstructure evolution, dynamic recovery and recrystallization: Application to high entropy alloys, Int. J. Mech. Sci. 177, 105567 (2020).

X. Lu, J. Zhao, C. Yu, Z. Li, Q. Kan, G. Kang, and X. Zhang, Cyclic plasticity of an interstitial high-entropy alloy: experiments, crystal plasticity modeling, and simulations, J. Mech. Phys. Solids 142, 103971 (2020).

X. Zhang, X. Lu, J. Zhao, Q. Kan, Z. Li, and G. Kang, Temperature effect on tensile behavior of an interstitial high entropy alloy: Crystal plasticity modeling, Int. J. Plast. 150, 103201 (2022).

N. Zaafarani, D. Raabe, R. N. Singh, F. Roters, and S. Zaefferer, Three-dimensional investigation of the texture and microstructure below a nanoindent in a Cu single crystal using 3D EBSD and crystal plasticity finite element simulations, Acta Mater. 54, 1863 (2006).

Z. Zhao, W. Mao, F. Roters, and D. Raabe, A texture optimization study for minimum earing in aluminium by use of a texture component crystal plasticity finite element method, Acta Mater. 52, 1003 (2004).

D. Raabe, and F. Roters, Using texture components in crystal plasticity finite element simulations, Int. J. Plast. 20, 339 (2004).

F. Roters, P. Eisenlohr, L. Hantcherli, D. D. Tjahjanto, T. R. Bieler, and D. Raabe, Overview of constitutive laws, kinematics, homogenization and multiscale methods in crystal plasticity finite-element modeling: Theory, experiments, applications, Acta Mater. 58, 1152 (2010).

N. Zaafarani, D. Raabe, F. Roters, and S. Zaefferer, On the origin of deformation-induced rotation patterns below nanoindents, Acta Mater. 56, 31 (2008).

E. Demir, D. Raabe, N. Zaafarani, and S. Zaefferer, Investigation of the indentation size effect through the measurement of the geometrically necessary dislocations beneath small indents of different depths using EBSD tomography, Acta Mater. 57, 559 (2009).

H. Zhang, and X. Dong, Experimental and numerical studies of coupling size effects on material behaviors of polycrystalline metallic foils in microscale plastic deformation, Mater. Sci. Eng.-A 658, 450 (2016).

M. J. Lewandowski, and S. Stupkiewicz, Size effects in wedge indentation predicted by a gradient-enhanced crystal-plasticity model, Int. J. Plast. 109, 54 (2018).

P. Hu, Y. Liu, Y. Zhu, and L. Ying, Crystal plasticity extended models based on thermal mechanism and damage functions: Application to multiscale modeling of aluminum alloy tensile behavior, Int. J. Plast. 86, 1 (2016).

J. Lemaitre, A continuous damage mechanics model for ductile fracture, J. Eng. Mater. Tech. 107, 83 (1985).

N. Bonora, D. Gentile, A. Pirondi, and G. Newaz, Ductile damage evolution under triaxial state of stress: theory and experiments, Int. J. Plast. 21, 981 (2005).

A. Pirondi, and N. Bonora, Modeling ductile damage under fully reversed cycling, Comput. Mater. Sci. 26, 129 (2003).

A. Pirondi, N. Bonora, D. Steglich, W. Brocks, and D. Hellmann, Simulation of failure under cyclic plastic loading by damage models, Int. J. Plast. 22, 2146 (2006).

J. Wang, and Y. Yao, An entropy-based failure prediction model for the creep and fatigue of metallic materials, Entropy 21, 1104 (2019).

Y. Yao, X. He, L. M. Keer, and M. E. Fine, A continuum damage mechanics-based unified creep and plasticity model for solder materials, Acta Mater. 83, 160 (2015).

K. Tanaka, and T. Mura, A dislocation model for fatigue crack initiation, J. Appl. Mech. 48, 97 (1981).

L. Liu, J. Wang, T. Zeng, and Y. Yao, Crystal plasticity model to predict fatigue crack nucleation based on the phase transformation theory, Acta Mech. Sin. 35, 1033 (2019).

F. Bahadur, K. Biswas, and N. P. Gurao, Micro-mechanisms of microstructural damage due to low cycle fatigue in CoCuFeMnNi high entropy alloy, Int. J. Fatigue 130, 105258 (2020).

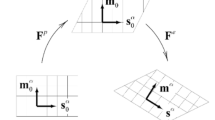

R. J. Asaro, and A. Needleman, Overview no. 42 Texture development and strain hardening in rate dependent polycrystals, Acta Metall. 33, 923 (1985).

Y. G. Huang, A user-material subroutine incorporating single crystal plasticity in the abaqus finite element program, Mech. Report 178, Division of Applied Sciences, Harvard University, Cambridge, 1991.

L. M. Kachanov, and D. Krajcinovic, Introduction to continuum damage mechanics, J. Appl. Mech. 54, 481 (1987).

R. J. Asaro, Crystal plasticity, J. Appl. Mech. 50, 921 (1983).

J. Lemaitre, A Course on Damage Mechanics (Springer Berlin Heidelberg, Berlin, Heidelberg, 1996).

C. J. Tong, M. R. Chen, J. W. Yeh, S. J. Lin, S. K. Chen, T. T. Shun, and S. Y. Chang, Mechanical performance of the Al x CoCrCuFeNi high-entropy alloy system with multiprincipal elements, Metall. Mat. Trans. A 36, 1263 (2005).

M. W. Xie, G. Chen, J. Yang, and W. L. Xu, Temperature- and rate-dependent deformation behaviors of SAC305 solder using crystal plasticity model, Mech. Mater. 157, 103834 (2021).

C. R. Weinberger, C. C. Battaile, T. E. Buchheit, and E. A. Holm, Incorporating atomistic data of lattice friction into BCC crystal plasticity models, Int. J. Plast. 37, 16 (2012).

S. Nemat-Nasser, T. Okinaka, and L. Ni, A physically-based constitutive model for bcc crystals with application to polycrystalline tantalum, J. Mech. Phys. Solids 46, 1009 (1998).

M. J. Serenelli, M. A. Bertinetti, and J. W. Signorelli, Investigation of the dislocation slip assumption on formability of BCC sheet metals, Int. J. Mech. Sci. 52, 1723 (2010).

G. Laplanche, P. Gadaud, O. Horst, F. Otto, G. Eggeler, and E. P. George, Temperature dependencies of the elastic moduli and thermal expansion coefficient of an equiatomic, single-phase CoCrFeMnNi high-entropy alloy, J. Alloys Compd. 623, 348 (2015).

Acknowledgements

This work was supported by the Shaanxi Science and Technology Innovation Team (Grant No. 2022TD-05), Shaanxi “Sanqin Scholar” Innovation Team, and the Natural Science Basic Research Plan in Shaanxi Province of China (Grant No. 2021JQ-077).

Author information

Authors and Affiliations

Corresponding author

Additional information

Author contributions

Yingying Wang and Jundong Wang developed the constitutive model and wrote the first draft of manuscript. Mingqi Lei developed the 2D polycrystalline finite element model. Yao Yao proposed the idea, supervised the research, and revised the manuscript.

Rights and permissions

About this article

Cite this article

Wang, Y., Wang, J., Lei, M. et al. A crystal plasticity coupled damage constitutive model of high entropy alloys at high temperature. Acta Mech. Sin. 38, 122116 (2022). https://doi.org/10.1007/s10409-022-22116-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10409-022-22116-x