Abstract

It is commonly known that riblets with sharper tip generally have better turbulent drag reduction capacity, which, however, poses great challenges for manufacturing and makes the riblets vulnerable to tip erosion. In this study, we show that a scalloped riblet which is not as sharp in the tip as corresponding triangular riblet with same height-width ratio, nevertheless has a larger protrusion height, a quantity solely depending on the riblet shape and calculated through a boundary element algorithm in this study, and thus a higher projected drag reduction rate. In addition, it is found that, when subjected to tip rounding, this scalloped riblet performs better in terms of protrusion height than corresponding parabolic riblet, which indicates stronger resilience to riblet tip erosion. With the class of scalloped riblets, designed by smoothly connecting two third-order polynomials and thus the tip sharpness and valley curvature can be well defined, it is revealed that two mechanisms, one for the valley curvature at the viscous limit and one for the tip sharpness at infinite deep limit, determine the protrusion height, and thus the projected drag reduction capacity. Direct numerical simulations are then carried out to investigate controlled boundary layer transition with the scalloped riblet of width s+ = 20 and s+ = 60. A 7.8% drag reduction in the turbulent region is found for the smaller riblet with a preferable transition delay, while for the larger riblet transition is promoted and drag is increased in the turbulent region. It is also found that the area fraction of high drag region around the riblet tips is basically the same for the two cases. Surprisingly, even higher drag is found around the tip region for the smaller drag-reducing riblets. On the other hand, a much smaller drag coefficient is found in the valley of the smaller riblet, which results in the reduction of turbulent drag. It is thus inferred that the issue of sharp riblet tip, that hard to manufacture and deteriorate substantially when subjected to tip erosion, could be mitigated by optimization of the riblet geometry.

摘要

一般而言, 在利用沟槽面进行湍流减阻中, 其顶部越尖锐, 湍流减阻效果往往越好. 但尖锐的顶部不利于沟槽面的制造生产, 并 且容易受到顶部磨损的影响. 本研究发现对于所提出的由两个三次多项式函数光滑连接构成的曲面沟槽, 尽管其顶部不如具有同样高 宽比的三角形沟槽尖锐, 但其突出高度却大于三角形沟槽, 进而有更高的预估减阻率. 同时, 该曲面沟槽对于顶部磨损相对不敏感, 并 且在所考虑的磨损后, 其性能优于相应的抛物线型沟槽. 利用这类曲面沟槽, 我们发现了两种决定突出高度的作用机制, 一是在粘性极 限的谷曲率, 另一个是在沟槽无限深极限的顶部曲率, 而相关研究中用到沟槽的突出高度都是由这两种机制共同决定. 针对该曲面沟 槽, 利用直接数值模拟技术对宽度为s+ = 20和s+ = 60 时的边界层转捩问题进行了数值仿真, 发现与无控制下流动相比, s+ = 20 算例不 仅在湍流段有与预估相符的7.8%减阻率, 并且使转捩得到了推迟, 而s+ = 60算例在湍流段有增阻效果, 并且使转捩提前发生. 通过对比 两个算例中沟槽面的阻力分布以及瞬时流场结构, 发现两者高阻力区域和低阻力区域面积基本相同, 并且在沟槽顶部反而是减阻算例 的阻力系数大, 而在沟槽底部减阻算例的阻力系数要远远小于增阻算例, 即增阻效果主要来源于沟槽底部的低阻力区. 以上研究表明, 沟槽顶部过于尖锐而导致的难以加工、易受磨损等问题, 可以通过合理的设计沟槽形状得到缓和.

Similar content being viewed by others

References

A. Abbas, G. Bugeda, E. Ferrer, S. Fu, J. Periaux, J. Pons-Prats, E. Valero, and Y. Zheng, Drag reduction via turbulent boundary layer flow control, Sci. China Tech. Sci. 60, 1281 (2017).

M. Quadrio, and P. Ricco, Critical assessment of turbulent drag reduction through spanwise wall oscillations, J. Fluid Mech. 521, 251 (2004).

R. García-Mayoral, and J. Jiménez, Drag reduction by riblets, Philos. Trans. A Math. Phys. Eng. Sci. 369, 1412 (2011).

X. Cui, N. Jiang, X. Zheng, and Z. Tang, Active control of multiscale features in wall-bounded turbulence, Acta Mech. Sin. 36, 12 (2020).

L. Lu, D. Li, Z. Gao, Z. Cao, Y. Bai, and J. Zheng, Characteristics of array of distributed synthetic jets and effect on turbulent boundary layer, Acta Mech. Sin. 36, 1171 (2020).

Q. J. Xia, W. X. Huang, and C. X. Xu, Direct numerical simulation of a turbulent boundary layer over an anisotropic compliant wall, Acta Mech. Sin. 35, 384 (2019).

A. Sharma, and R. García-Mayoral, Turbulent flows over dense filament canopies, J. Fluid Mech. 888, A2 (2020), arXiv: 1907.04020.

A. Rastegari, and R. Akhavan, The common mechanism of turbulent skin-friction drag reduction with superhydrophobic longitudinal microgrooves and riblets, J. Fluid Mech. 838, 68 (2018).

M. J. Walsh, and L. M. Weinstein, Drag and heat-transfer characteristics of small longitudinally ribbed surfaces, AIAA J. 17, 770 (1979).

M. Walsh, in Turbulent boundary layer drag reduciton using riblets: Proceedings of the AIAA 20th Aerospace Sciences Meeting, Orlando, 1982.

M. J. Walsh, Riblets as a viscous drag reduction technique, AIAA J. 21, 485 (1983).

M. J. Walsh, Effect of detailed surface geometry on riblet drag reduction performance, J. Aircraft 27, 572 (1990).

A. Hooshmand, R. Youngs, J. Wallace, and J. Balint, in An experimental study of changes in the structure of a turbulent boundary layer due to surface geometry changes: Proceedings of the AIAA 21st Aerospace Sciences Meeting, Reno, 1983.

K. N. Liu, D. D. Joseph, O. Riccius, and C. Christodoulou, Drag reduction in pipes lined with riblets, AIAA J. 28, 1697 (1990).

D. W. Bechert, M. Bruse, W. Hage, J. G. T. van der Hoeven, and G. Hoppe, Experiments on drag-reducing surfaces and their optimization with an adjustable geometry, J. Fluid Mech. 338, 59 (1997).

W. Li, and H. Liu, Two-point statistics of coherent structures in turbulent flow over riblet-mounted surfaces, Acta Mech. Sin. 35, 457 (2019).

K. S. Choi, Near-wall structure of a turbulent boundary layer with riblets, J. Fluid Mech. 208, 417 (1989).

K. S. Choi, Near-wall structure of turbulent boundary layer with spanwise-wall oscillation, Phys. Fluids 14, 2530 (2002).

S. J. Lee, and S. H. Lee, Flow field analysis of a turbulent boundary layer over a riblet surface, Exp. Fluids 30, 153 (2001).

D. W. Bechert, and M. Bartenwerfer, The viscous flow on surfaces with longitudinal ribs, J. Fluid Mech. 206, 105 (1989).

P. Luchini, F. Manzo, and A. Pozzi, Resistence of a grooved surface to parallel flow and cross-flow, J. Fluid Mech. 228, 87 (1991).

D. B. Goldstein, and T. C. Tuan, Secondary flow induced by riblets, J. Fluid Mech. 363, 115 (1998).

H. Choi, P. Moin, and J. Kim, Direct numerical simulation of turbulent flow over riblets, J. Fluid Mech. 255, 503 (1993).

J. Kim, P. Moin, and R. Moser, Turbulence statistics in fully developed channel flow at low Reynolds number, J. Fluid Mech. 177, 133 (1987).

R. García-mayoral, and J. Jiménez, Hydrodynamic stability and breakdown of the viscous regime over riblets, J. Fluid Mech. 678, 317 (2011).

D. Bechert, M. Bartenwerfer, and G. Hoppe, Turbulent drag reduction by nonplanar surfaces—A survey on the research at TU/DLR Berlin. In: Structure of Turbulence and Drag Reduction. International Union of Theoretical and Applied Mechanics (Springer-Verlag, Berlin, Heidelberg, 1990).

R. García-Mayoral, The interaction of riblets with wall-bounded turbulence, Dissertation for Doctoral Degree, Madrid: Universidad Politécnica de Madrid, 2011.

C. Liu, and L. Chen, Parallel DNS for vortex structure of late stages of flow transition, Comput. Fluids 45, 129 (2011).

Y. Wang, Y. Yang, G. Yang, and C. Liu, DNS study on vortex and vorticity in late boundary layer transition, Commun. Comput. Phys. 22, 441 (2017).

S. K. Lele, Compact finite difference schemes with spectral-like resolution, J. Comput. Phys. 103, 16 (1992).

C. W. Shu, and S. Osher, Efficient implementation of essentially nonoscillatory shock-capturing schemes, II, J. Comput. Phys. 83, 32 (1989).

L. Jiang, H. Shan, C. Liu, and M. Visbal, Non-reflecting boundary conditions for DNS in curvilinear coordinates. In: Recent Advances in DNS and LES, Fluid Mechanics and Its Applications (Springer, Dordrecht, 1999). Vol. 54.

L. Chen, X. Liu, M. Oliveira, and C. Liu, in DNS for late stage structure of flow transition on a flat-plate boundary layer: Proceedings of the AIAA 48th Aerospace Sciences Meeting, Orlando, 2010.

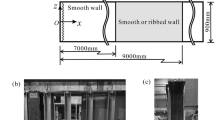

S. Klumpp, M. Meinke, and W. Schroder, Numerical simulation of riblet controlled spatial transition in a zero-pressure-gradient boundary layer, Flow Turbulence Combust 85, 57 (2010).

A. Boomsma, and F. Sotiropoulos, Riblet drag reduction in mild adverse pressure gradients: A numerical investigation, Int. J. Heat Fluid Flow 56, 251 (2015).

R. García-Mayoral, and J. Jiménez, Scaling of turbulent structures in riblet channels up to Reτ ≈ 550, Phys. Fluids, 24, 105101 (2012).

J. Jiménez, On the structure and control of near wall turbulence, Phys. Fluids 6, 944 (2014).

D. Goldstein, R. Handler, and L. Sirovich, Direct numerical simulation of turbulent flow over a modeled riblet covered surface, J. Fluid Mech. 302, 333 (1995).

D. C. Chu, and G. E. Karniadakis, A direct numerical simulation of laminar and turbulent flow over riblet-mounted surfaces, J. Fluid Mech. 250, 1 (1993).

G. R. Grek, V. V. Kozlov, and S. V. Titarenko, An experimental study of the influence of riblets on transition, J. Fluid Mech. 315, 31 (1996).

C. Q. Liu, Y. Q. Wang, Y. Yang, and Z. W. Duan, New omega vortex identification method, Sci. China-Phys. Mech. Astron. 59, 684711 (2016).

N. Gui, L. Ge, P. Cheng, X. Yang, J. Tu, and S. Jiang, Comparative assessment and analysis of Rortex vortex in swirling jets, J. Hydrodyn. 31, 495 (2019).

L. Wang, Z. Zheng, W. Cai, and W. Li, Extension Omega and Omega-Liutex methods applied to identify vortex structures in viscoelastic turbulent flow, J. Hydrodyn. 31, 911 (2019).

Y. Zhang, X. Hu, W. Lan, Y. Liu, M. Wang, and J. Wang, Application of Omega vortex identification method in cavity buffeting noise, J. Hydrodyn. 33, 259 (2021).

X. Y. Jiang, C. B. Lee, C. R. Smith, J. W. Chen, and P. F. Linden, Experimental study on low-speed streaks in a turbulent boundary layer at low Reynolds number, J. Fluid Mech. 903, A6 (2020).

S. A. Vagner, S. A. Patlazhan, C. A. Serra, and D. Funfschilling, Vortex flow evolution in a growing microdroplet during co-flow in coaxial capillaries, Phys. Fluids 33, 072010 (2021).

Funding

This work was supported by the National Natural Science Foundation of China (Grant No. 11702159), and the EU-China Joint Project Drag Reduction via Turbulent Boundary Layer Flow Control (Grant No. 690623).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Y., Huang, Y. & Fu, S. On the tip sharpness of riblets for turbulent drag reduction. Acta Mech. Sin. 38, 321389 (2022). https://doi.org/10.1007/s10409-022-09019-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10409-022-09019-x