Abstract

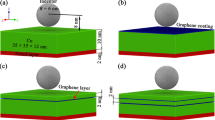

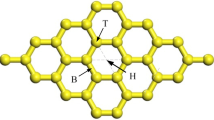

Molecular dynamics (MD) simulations of the titanium-graphene nanocomposites (TiGNCs) under uniaxial tension are carried out to investigate the mechanical properties and reinforcement mechanism of graphene in composites. It is found that introduction of mechanically robust graphene limits the strain-induced dislocation and amorphization and thereby highly improves the mechanical properties of metallic titanium that are greatly affected by the crystal stacking orientation of graphene and titanium layers. The thickness of titanium layers, interface interaction and working temperature play an important role in the mechanical strength and elastic moduli of composites. The results show the mechanical properties of TiGNCs are monotonically enhanced with reduction of the titanium layer thickness and working temperature, and the Young’s modulus obtained by MD simulation are higher than that predicted by the rule of mixture (ROM) due to consideration of interfacial interaction in computational calculation. In addition, once the critical thickness of titanium layer is reached, graphene wrinkles are induced in composites because of Poisson’s effect induced large lateral compression stress in the interface region. This study provides helpful insights into fundamental understanding reinforcing mechanism of graphene and ultimately contribute to the optimal design and performance of mechanically robust graphene-based metallic composites.

Graphic abstract

Similar content being viewed by others

References

Stankovich, S., Dommett, G.H.B., Kohlhaas, K.M., et al.: Graphene-based composite materials. Nature 442, 282–286 (2006)

Novoselov, K.S., Fal′ko, V.I., Colombo, L., et al.: A roadmap for graphene. Nature 490, 192–200 (2012)

Xu, X., Rong, D., Lim, C.W., et al.: An analytical symplectic approach to the vibration analysis of orthotropic graphene sheets. Acta Mech. Sin. 33, 912–925 (2017)

Pan, D., Li, Y., Wang, T.-C., et al.: Bending-induced extension in two-dimensional crystals. Acta Mech. Sin. 33, 71–76 (2017)

Meng, X.-H., Li, M., Kang, Z., et al.: Folding of multi-layer graphene sheets induced by van der Waals interaction. Acta Mech. Sin. 30, 410–417 (2014)

Zhao, Y., Dong, S., Yu, P., et al.: Loading direction-dependent shear behavior at different temperatures of single-layer chiral graphene sheets. Acta Mech. Sin. 34, 542–548 (2018)

Chu, K., Wang, X., Li, Y., et al.: Thermal properties of graphene/metal composites with aligned graphene. Mater. Des. 140, 85–94 (2018)

Wang, S., Han, S., Xin, G., et al.: High-quality graphene directly grown on Cu nanoparticles for Cu-graphene nanocomposites. Mater. Des. 139, 181–187 (2018)

Khalil, I., Rahmati, S., Muhd Julkapli, N., et al.: Graphene metal nanocomposites—Recent progress in electrochemical biosensing applications. J. Ind. Eng. Chem. 59, 425–439 (2018)

Montazeri, A., Mobarghei, A.: Nanotribological behavior analysis of graphene/metal nanocomposites via MD simulations: new concepts and underlying mechanisms. J. Phys. Chem. Solids 115, 49–58 (2018)

Hynes Navasingh, R.J., Kumar, R., Marimuthu, K., et al.: Graphene-based nano metal matrix composites: a review. In: Nanocarbon and Its Composites, Elsevier. 153–170 (2019)

Bashirvand, S., Montazeri, A.: New aspects on the metal reinforcement by carbon nanofillers: a molecular dynamics study. Mater. Des. 91, 306–313 (2016)

Guo, S.-J., Yang, Q.-S., He, X.Q., et al.: Modeling of interface cracking in copper–graphite composites by MD and CFE method. Compos. B Eng. 58, 586–592 (2014)

Hwang, J., Yoon, T., Jin, S.H., et al.: Enhanced mechanical properties of graphene/copper nanocomposites using a molecular-level mixing process. Adv. Mater. 25, 6724–6729 (2013)

Song, Y., Chen, Y., Liu, W.W., et al.: Microscopic mechanical properties of titanium composites containing multi-layer graphene nanofillers. Mater. Des. 109, 256–263 (2016)

Khan, M.E., Khan, M.M., Cho, M.H.: Recent progress of metal–graphene nanostructures in photocatalysis. Nanoscale 10, 9427–9440 (2018)

Peng, Y., Lin, D., Justin Gooding, J., et al.: Flexible fiber-shaped non-enzymatic sensors with a graphene-metal heterostructure based on graphene fibres decorated with gold nanosheets. Carbon 136, 329–336 (2018)

Bhattacharya, A., Bhattacharya, S., Majumder, C., et al.: Transition-metal decoration enhanced room-temperature hydrogen storage in a defect-modulated graphene sheet. J. Phys. Chem. C 114, 10297–10301 (2010)

Leong, W.S., Gong, H., Thong, J.T.L.: Low-contact-resistance graphene devices with nickel-etched-graphene contacts. ACS Nano 8, 994–1001 (2014)

Bartolucci, S.F., Paras, J., Rafiee, M.A., et al.: Graphene–aluminum nanocomposites. Mater. Sci. Eng. A 528, 7933–7937 (2011)

Bastwros, M., Kim, G.-Y., Zhu, C., et al.: Effect of ball milling on graphene reinforced Al6061 composite fabricated by semi-solid sintering. Compos. B Eng. 60, 111–118 (2014)

Shin, S.E., Choi, H.J., Shin, J.H., et al.: Strengthening behavior of few-layered graphene/aluminum composites. Carbon 82, 143–151 (2015)

Yi, C., Chen, X., Gou, F., et al.: Direct measurements of the mechanical strength of carbon nanotube-Aluminum interfaces. Carbon 125, 93–102 (2017)

Yi, C., Bagchi, S., Dmuchowski, C.M., et al.: Direct nanomechanical characterization of carbon nanotubes-titanium interfaces. Carbon 132, 548–555 (2018)

Rezaei, R.: Tensile mechanical characteristics and deformation mechanism of metal-graphene nanolayered composites. Comput. Mater. Sci. 151, 181–188 (2018)

Weng, S., Ning, H., Fu, T., et al.: Molecular dynamics study of strengthening mechanism of nanolaminated graphene/Cu composites under compression. Sci. Rep. 8, 3089 (2018)

Liu, X., Wang, F., Wang, W., et al.: Interfacial strengthening and self-healing effect in graphene-copper nanolayered composites under shear deformation. Carbon 107, 680–688 (2016)

Zhang, H., Li, X., Su, J., et al.: Modulation of columnar crystals of magnetron sputtered Ti thin films. Thin Solid Films 689, 137512 (2019)

Geetha, M., Singh, A.K., Asokamani, R., et al.: Ti based biomaterials, the ultimate choice for orthopaedic implants–A review. Prog. Mater. Sci. 54, 397–425 (2009)

Kuzumaki, T., Ujiie, O., Ichinose, H., et al.: Mechanical characteristics and preparation of carbon nanotube fiber-reinforced Ti composite. Adv. Eng. Mater. 2, 416–418 (2000)

Fonseca, A.F., Liang, T., Zhang, D., et al.: Graphene–titanium interfaces from molecular dynamics simulations. ACS Appl. Mater. Interfaces 9, 33288–33297 (2017)

Fonseca, A.F., Liang, T., Zhang, D., et al.: Titanium-carbide formation at defective curved graphene-titanium interfaces. MRS Adv. 3, 457–462 (2018)

Khomyakov, P.A., Giovannetti, G., Rusu, P.C., et al.: First-principles study of the interaction and charge transfer between graphene and metals. Phys. Rev. B 79, 195425 (2009)

Chen, L., Luo, J., Wang, Q., et al.: First-principles study of cohesion strength and stability of titanium–carbon interfaces using vdW interaction. J. Phys. Condens. Matter 32, 145001 (2020)

Ackland, G.J.: Theoretical study of titanium surfaces and defects with a new many-body potential. Philos. Mag. A 66, 917–932 (1992)

Stuart, S.J., Tutein, A.B., Harrison, J.A.: A reactive potential for hydrocarbons with intermolecular interactions. J. Chem. Phys. 112, 6472–6486 (2000)

Bridier, F., Villechaise, P., Mendez, J.: Analysis of the different slip systems activated by tension in a α/β titanium alloy in relation with local crystallographic orientation. Acta Mater. 53, 555–567 (2005)

Pei, Q.-X., Zhang, Y.-W., Shenoy, V.B.: Mechanical properties of methyl functionalized graphene: a molecular dynamics study. Nanotechnology 21, 115709 (2010)

Shenderova, O.A., Brenner, D.W., Omeltchenko, A., et al.: Atomistic modeling of the fracture of polycrystalline diamond. Phys. Rev. B 61, 3877–3888 (2000)

Zhao, H., Aluru, N.R.: Temperature and strain-rate dependent fracture strength of graphene. J. Appl. Phys. 108, 064321 (2010)

Duan, K., Li, L., Hu, Y., et al.: Interface mechanical properties of graphene reinforced copper nanocomposites. Mater. Res. Express. 4, 115020 (2017)

Piątek, A., Nowak, R., Gburski, Z.: A titanium-decorated fullerene cluster—a molecular dynamics simulation. In: Perspectives of Nanoscience and Nanotechnology, Trans Tech Publications Ltd. pp. 109–116 (2008)

Plimpton, S.: Fast parallel algorithms for short-range molecular dynamics. J. Comp. Phys. 117, 1–19 (1995)

Stukowski, A.: Visualization and analysis of atomistic simulation data with OVITO—the Open Visualization Tool. Modell. Simul. Mater. Sci. Eng. 18, 015012 (2010)

Hoover, W.G.: Canonical dynamics: equilibrium phase-space distributions. Phys. Rev. A 31, 1695–1697 (1985)

Hoover, W.G.: Constant-pressure equations of motion. Phys. Rev. A 34, 2499–2500 (1986)

Memarian, F., Fereidoon, A., Darvish Ganji, M.: Graphene Young’s modulus: molecular mechanics and DFT treatments. Superlattices Microstruct. 85, 348–356 (2015)

Zhang, J.Y., Zhang, X., Liu, G., et al.: Scaling of the ductility with yield strength in nanostructured Cu/Cr multilayer films. Scripta Mater. 63, 101–104 (2010)

Duan, K., Zhu, F., Tang, K., et al.: Effects of chirality and number of graphene layers on the mechanical properties of graphene-embedded copper nanocomposites. Comput. Mater. Sci. 117, 294–299 (2016)

Acknowledgments

This work is financially supported by the National Natural Science Foundation of China (Grants U1737106, 51705411, 11772278 and 11502221), the Jiangxi Provincial Outstanding Young Talents Program (Grant 20192BCBL23029), the Fundamental Research Funds for the Central Universities (Xiamen University: Grants 20720180014, 20720180018 and 20720160088), Shaanxi Provincial Natural Science Foundation (Grant 2018JM5022), Fujian Provincial Department of Science & Technology (Grant 2017J05028), “111” Project (Grant B16029) and the 1000 Talents Program from Xiamen University.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Tang, W., Zhang, J., Wu, J. et al. Mechanical properties and enhancement mechanisms of titanium-graphene nanocomposites. Acta Mech. Sin. 36, 855–865 (2020). https://doi.org/10.1007/s10409-020-00968-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10409-020-00968-x