Abstract

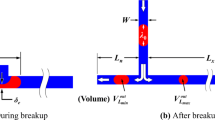

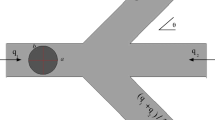

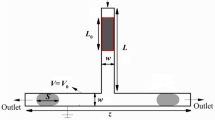

Passive asymmetric breakups of a droplet could be done in many microchannels of various geometries. In order to study the effects of different geometries on the asymmetric breakup of a droplet, four types of asymmetric microchannels with the topological equivalence of geometry are designed, which are T-90, Y-120, Y-150, and I-180 microchannels. A three-dimensional volume of fluid multiphase model is employed to investigate the asymmetric rheological behaviors of a droplet numerically. Three regimes of rheological behaviors as a function of the capillary numbers Ca and the asymmetries As defined by As = (b1 − b2)/(b1 + b2) (where b1 and b2 are the widths of two asymmetric sidearms) have been observed. A power law model based on three major factors (Ca, As and the initial volume ratio r 0) is employed to describe the volume ratio of two daughter droplets. The analysis of pressure fields shows that the pressure gradient inside the droplet is one of the major factors causing the droplet translation during its asymmetric breakup. Besides the above similarities among various microchannels, the asymmetric breakup in them also have some slight differences as various geometries have different enhancement or constraint effects on the translation of the droplet and the cutting action of flows. It is disclosed that I-180 microchannel has the smallest critical capillary number, the shortest splitting time, and is hardest to generate satellite droplets.

Similar content being viewed by others

References

Abate AR, Weitz DA (2011) Faster multiple emulsification with drop splitting. Lab Chip 11(11):1911–1915

Afkhami S, Leshansky AM, Renardy Y (2011) Numerical investigation of elongated drops in a microfluidic T-junction. Phys Fluids 23(2):022002

Bedram A, Moosavia A, Hannani SK (2015) A novel method for producing unequal sized droplets in microand nanofluidic channels. Eur Phys J E 38:96

Bentley B, Leal L (1986) An experimental investigation of drop deformation and breakup in steady, two-dimensional linear flows. J Fluid Mech 167:241–283

Brackbill JU, Kothe DB, Zemach C (1992) A continuum method for modeling surface tension. J Comput Phys 100:335–354

Carlson A, Do-Quang M, Amberg G (2010) Droplet dynamics in a bifurcating channel. Int J Multiph Flow 36(5):397–405

Che Z, Nguyen N-T, Wong TN (2011) Hydrodynamically mediated breakup of droplets in microchannels. Appl Phys Lett 98(5):054102

Cubaud T (2009) Deformation and breakup of high-viscosity droplets with symmetric microfluidic cross flows. Phys Rev E 80(2):026307

De Menech M, Garstecki P, Jousse F, Stone H (2008) Transition from squeezing to dripping in a microfluidic T-shaped junction. J Fluid Mech 595(1):141–161

Dendukuri D, Tsoi K, Hatton TA, Doyle PS (2005) Controlled synthesis of nonspherical microparticles using microfluidics. Langmuir 21(6):2113–2116

Galinat S, Torres LG, Masbernat O, Guiraud P, Risso F, Dalmazzone C, Noik C (2007) Breakup of a drop in a liquid-liquid pipe flow through an orifice. AIChE J 53(1):56–68

Guan J, Liu JX, Li XD, Tao J, Wang JT (2015) Stokes flow in a two-dimensional micro-device combined by a cross-slot and a microfluidic four-roll mill. Z Angew Math Phys 66:149–169

Janssen JMH, Meijer HEM (1993) Droplet breakup mechanisms. J Rheol 37(4):597–608

Leshansky AM, Pismen LM (2009) Breakup of drops in a microfluidic T junction. Phys Fluids 21(2):023303

Li QX, Chai ZH, Shi BC, Liang H (2014) Deformation and breakup of a liquid droplet past a solid circular cylinder: a lattice Boltzmann study. Phys Rev E 90(4):043015

Link D, Anna S, Weitz D, Stone H (2004) Geometrically mediated breakup of drops in microfluidic devices. Phys Rev Lett 92(5):054503

Ménétrier-Deremble L, Tabeling P (2006) Droplet breakup in microfluidic junctions of arbitrary angles. Phys Rev E 74(3):035303

Navot Y (1999) Critical behavior of drop breakup in axisymmetric viscous flow. Phys Fluids 11(5):990–996

Protière S, Bazant MZ, Weitz DA, Stone HA (2010) Droplet breakup in flow past an obstacle: a capillary instability due to permeability variations. Europhys Lett 92(5):54002

Salkin L, Courbin L, Panizza P (2012) Microfluidic breakups of confined droplets against a linear obstacle: the importance of the viscosity contrast. Phys Rev E 86(3):036317

Samie M, Salari A, Shafii MB (2013) Breakup of microdroplets in asymmetric T junctions. Phys Rev E 87(5):053003

Sang L, Hong Y, Wang F (2008) Investigation of viscosity effect on droplet formation in T-shaped microchannels by numerical and analytical methods. Microfluid Nanofluid 6(5):621–635

Schmit A, Salkin L, Courbin L, Panizza P (2015) Cooperative breakups induced by drop-to-drop interactions in one-dimensional flows of drops against micro-obstacles. Soft Matter 11(12):2454–2460

Seemann R, Brinkmann M, Pfohl T, Herminghaus S (2012) Droplet based microfluidics. Rep Prog Phys 75(1):016601

Sharma P, Fang TG (2014) Breakup of liquid jets from non-circular orifices. Exp Fluids 55(2):1666

Song H, Chen DL, Ismagilov RF (2006) Reactions in droplets in microflulidic channels. Angew Chem Int Ed 45(44):7336–7356

Stone HA (1994) Dynamics of drop deformation and breakup in viscous fluids. Annu Rev Fluid Mech 26:65–102

Stone HA, Leal LG (1989) Relaxation and breakup of an initially extended drop in an otherwise quiescent fluid. J Fluid Mech 198:399–427

Tan J, Xu J, Li S, Luo G (2008) Drop dispenser in a cross-junction microfluidic device: scaling and mechanism of break-up. Chem Eng J 136(2):306–311

Taylor GI (1934) The formation of emulsions in definable fields of flow. Proc R Soc Lond Ser A 146(858):501–523

Teh S-Y, Lin R, Hung L-H, Lee AP (2008) Droplet microfluidics. Lab Chip 8(2):198–220

Wang J, Yu D (2015) Asymmetry of flow fields and asymmetric breakup of a droplet. Microfluid Nanofluid 18(4):709–715

Wang J-T, Wang J, Han J-J (2011) Fabrication of advanced particles and particle-based materials assisted by droplet-based microfluidics. Small 7(13):1728–1754

Wang J, Han J, Yu D (2012) Numerical studies of geometry effects of a two-dimensional microfluidic four-roll mill on droplet elongation and rotation. Eng Anal Bound Elem 36(10):1453–1464

Xu Q, Hashimoto M, Dang TT, Hoare T, Kohane DS, Whitesides GM, Langer R, Anderson DG (2009) Preparation of monodisperse biodegradable polymer microparticles using a microfluidic flow-focusing device for controlled drug delivery. Small 5(13):1575–1581

Zheng B, Tice JD, Roach LS, Ismagilov RF (2004) A droplet-based, composite PDMS/glass capillary microfluidic system for evaluating protein crystallization conditions by microbatch and vapor-diffusion methods with on-chip X-ray diffraction. Angew Chem Int Ed 43(19):2508–2511

Acknowledgments

The authors gratefully acknowledge the financial support provided to this study by Major State Basic Research Development Program of China (973 Program) (No. 2012CB720305), and by the National Science Foundation of China (21376162, 21576185).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zheng, M., Ma, Y., Jin, T. et al. Effects of topological changes in microchannel geometries on the asymmetric breakup of a droplet. Microfluid Nanofluid 20, 107 (2016). https://doi.org/10.1007/s10404-016-1776-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10404-016-1776-4