Abstract

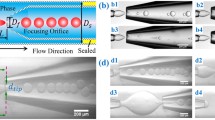

We report the droplet generation behavior of a microfluidic droplet generator with a controllable deformable membrane wall using experiments and analytical model. The confinement at the droplet generation junction is controlled by using external pressure, which acts on the membrane, to generate droplets smaller than junction size (with other parameters fixed) and stable and monodispersed droplets even at higher capillary numbers. A non-dimensional parameter, i.e., controlling parameter K p, is used to represent the membrane deformation characteristics due to the external pressure. We investigate the effect of the controlled membrane deformation (in terms of K p), viscosity ratio λ and flow rate ratio r on the droplet size and mobility. A correlation is developed to predict droplet size in the controllable deformable microchannel in terms of the controlling parameter K p, viscosity ratio λ and flow rate ratio r. Due to the deflection of the membrane wall, we demonstrate that the transition from the stable dripping regime to the unstable jetting regime is delayed to a higher capillary number Ca (as compared to rigid droplet generators), thus pushing the high throughput limit. The droplet generator also enables generation of droplets of sizes smaller than the junction size by adjusting the controlling parameter.

Similar content being viewed by others

References

Adzima BJ, Velankar SS (2006) Pressure drops for droplet flows in microfluidic channels. J Micromech Microeng 16:1504–1510. doi:10.1088/0960-1317/16/8/010

Anoop R, Sen AK (2015) Capillary flow enhancement in rectangular polymer microchannels with a deformable wall. Phys Rev E Stat Nonlinear Soft Matter Phys 92:013024. doi:10.1103/PhysRevE.92.013024

Baroud CN, Gallaire F, Danglaa R (2010) Dynamics of microfluidic droplets. Lab on a chip. doi:10.1039/c001191f

Bronstein IN, Semendjajew KA (1976) Taschenbuch der Mathematik. 17 Auflage ISBN 3 87144 0167

Bruus H (2007) Theoretical microfluidics. Oxford University Press, New York

Chabert M, Viovy J-L (2008) Microfluidic high-throughput encapsulation and hydrodynamic self-sorting of single cells. Proc Natl Acad Sci USA 105:3191–3196

Charcosset C, Limayem I, Fessi H (2004) The membrane emulsification process—a review. J Chem Technol Biotechnol 79:209–218. doi:10.1002/jctb.969

Cheung P, Toda-Peters K, Shen AQ (2012) In situ pressure measurement within deformable rectangular polydimethylsiloxane microfluidic devices. Biomicrofluidics 6:26501–2650112. doi:10.1063/1.4720394

Christopher GF, Anna SL (2007) Microfluidic methods for generating continuous droplet streams. J Phys D Appl Phys 40:R319–R336. doi:10.1088/0022-3727/40/19/R01

Garstecki P, Stone HA, Whitesides GM (2005) Mechanism for flow-rate controlled breakup in confined geometries: a route to monodisperse emulsions. Phys Rev Lett 94:164501. doi:10.1103/PhysRevLett.94.164501

Garstecki P, Fuerstman MJ, Stone HA, Whitesides GM (2006) Formation of droplets and bubbles in a microfluidic T-junction-scaling and mechanism of break-up. Lab Chip 6:437–446. doi:10.1039/b510841a

Gupta A, Kumar R (2009) Effect of geometry on droplet formation in the squeezing regime in a microfluidic T-junction. Microfluid Nanofluidics 8:799–812. doi:10.1007/s10404-009-0513-7

Gupta A, Kumar R (2010) Flow regime transition at high capillary numbers in a microfluidic T-junction: viscosity contrast and geometry effect. Phys Fluids 22:122001. doi:10.1063/1.3523483

Hsiung S-K, Chen C-T, Lee G-B (2006) Micro-droplet formation utilizing microfluidic flow focusing and controllable moving-wall chopping techniques. J Micromech Microeng 16:2403–2410. doi:10.1088/0960-1317/16/11/022

Huebner A, Sharma S, Srisa-Art M et al (2008) Microdroplets: a sea of applications? Lab Chip 8:1244–1254. doi:10.1039/b806405a

Johnston ID, McCluskey DK, Tan CKL, Tracey MC (2014) Mechanical characterization of bulk Sylgard 184 for microfluidics and microengineering. J Micromech Microeng 24:035017. doi:10.1088/0960-1317/24/3/035017

Kemna EWM, Schoeman RM, Wolbers F (2012) High-yield cell ordering and deterministic cell-in-droplet encapsulation using Dean flow in a curved microchannel. Lab Chip 12:2881–2887. doi:10.1039/c2lc00013j

Kohler JM, Henkel T (2005) Chip devices for miniaturized biotechnology. Appl Microbiol Biotechnol 69:113–125

Landau LD, Lifshitz EM (1986) Theory of elasticity. Pergamon Press, Oxford

Lee C-H, Hsiung S-K, Lee G-B (2007) A tunable microflow focusing device utilizing controllable moving walls and its applications for formation of micro-droplets in liquids. J Micromech Microeng 17:1121–1129. doi:10.1088/0960-1317/17/6/004

Lignel S, Drelich A, Sunagatullina D et al (2014) Differential scanning calorimetry analysis of W/O emulsions prepared by miniature scale magnetic agitation and microfluidics. Can J Chem Eng 92:337–343. doi:10.1002/cjce.21925

Lin Y-H, Lee C-H, Lee G-B (2008) Droplet formation utilizing controllable moving-wall structures for double-emulsion applications. J Microelectromech Syst 17:573–581. doi:10.1109/JMEMS.2008.924273

Link DR, Grasland-Mongrain E, Duri A (2006) Electric control of droplets in microfluidic devices. Angew Chem Int Ed Engl 45:2556–2560. doi:10.1002/anie.200503540

Liu M, Sun J, Sun Y (2009) Thickness-dependent mechanical properties of polydimethylsiloxane membranes. J Micromech Microeng 19:035028. doi:10.1088/0960-1317/19/3/035028

Meesters G, Vercoulen P, Marijnissen J, Scarlett B (1992) Generation of microj-sized droplets from the Tylor cone. J Aerosol Sci 23:37–49

Nie Z, Seo M, Xu S (2008) Emulsification in a microfluidic flow-focusing device: effect of the viscosities of the liquids. Microfluid Nanofluidics 5:585–594. doi:10.1007/s10404-008-0271-y

Pang Y, Kim H, Liu Z, Stone HA (2014) A soft microchannel decreases polydispersity of droplet generation. Lab Chip 14:4029–4034. doi:10.1039/c4lc00871e

Raj A, Sen AK (2016) Flow-induced deformation of deformable microchannels and its effect on pressure–flow characteristics. Microfluid Nanofluidics 20:31. doi:10.1007/s10404-016-1702-9

Reznik N, Williams R, Burns PN (2011) Investigation of vaporized submicron perfluorocarbon droplets as an ultrasound contrast agent. Ultrasound Med Biol 37:1271–1279. doi:10.1016/j.ultrasmedbio.2011.05.001

Sajeesh P, Doble M, Sen AK (2014) Hydrodynamic resistance and mobility of deformable objects in microfluidic channels. Biomicrofluidics 8:1–23. doi:10.1063/1.4897332

Sarrazin F, Prat L, Di Miceli N, Cristobal G, Link DR (2007) Mixing characterization inside microdroplets engineered on a microcoalescer. Chem Eng Sci 62:1042–1048

Schomburg WK (2011) Introduction to microsystem design. Springer. ISBN 978-3-642-19488-7

Sen AK, Darabi J (2007) Droplet ejection performance of a monolithic thermal inkjet print head. J Micromech Microeng 17:1420

Sugiura S, Nakajima M, Iwamoto S, Seki M (2001) Interfacial tension driven monodispersed droplet formation from microfabricated channel array. Langmuir 17:5562–5566. doi:10.1021/la010342y

Surya HPN, Parayil S, Banerjee U et al (2014) Alternating and merged droplets in a double T-junction microchannel. BioChip J. doi:10.1007/s13206-014-9103-1

Thangawng AL, Ruoff RS, Swartz MA, Glucksberg MR (2007) An ultra-thin PDMS membrane as a bio/micro–nano interface: fabrication and characterization. Biomed Microdevices 9:587–595. doi:10.1007/s10544-007-9070-6

Umbanhowar PB, Prasad V, Weitz DA (2000) Monodisperse emulsion generation via drop break off in a coflowing stream. Langmuir 16:347–351. doi:10.1021/la990101e

Van der Graaf S, Nisisako T, Schroën CGPH (2006) Lattice Boltzmann simulations of droplet formation in a T-shaped microchannel. Langmuir 22:4144–4152. doi:10.1021/la052682f

Vehring R, Foss WR, Lechuga-Ballesteros D (2007) Particle formation in spray drying. J Aerosol Sci 38:728–746. doi:10.1016/j.jaerosci.2007.04.005

Vladisavljevic GT, Khalid N, Neves MA (2013) Industrial lab-on-a-chip: design, applications and scale-up for drug discovery and delivery. Adv Drug Deliv Rev 65:1626–1663. doi:10.1016/j.addr.2013.07.017

Yang CG, Xu ZR, Wang JH (2010) Manipulation of droplets in microfluidic systems. TrAC Trends Anal Chem 29:141–157. doi:10.1016/j.trac.2009.11.002

Yoshida J, Ohmori K, Takeuchi H (2005) Treatment of ischemic limbs based on local recruitment of vascular endothelial growth factor-producing inflammatory cells with ultrasonic microbubble destruction. J Am Coll Cardiol 46:899–905

Zhang DF, Stone HA (1997) Drop formation in viscous flows at a vertical capillary tube. Phys Fluids 9:2234. doi:10.1063/1.869346

Acknowledgments

This work was supported by the Indian Institute of Technology Madras via Project No. ERP1314018RESFASHS. The authors also acknowledge the CNNP, IIT Madras for supporting the photolithography work.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

In order to find an expression for Δh max in terms of the local pressure gradient p d(z) − p c(z) across the membrane, we perform force balance on an infinitesimally small strip of the membrane wall of length dz, as shown in Fig. 12b. Depending upon the pressure gradient across the membrane, it will deflect in the direction of lesser pressure. In this case, here we are taking a case where pressure in the droplet channel is higher than in controlling channel, which results in the outward deflection of the membrane increasing the height of the channel. The force acting on the membrane due to the pressure difference across the membrane F p is balanced by the restoring force F r that holds the membrane on the bulk PDMS. The lateral component of this restoring force F r cos α cancels out due to symmetry (as there is no lateral movement of the membrane). The vertical component of the force due to pressure difference F p and the restoring force F r sin α balance each other as follows,

Here, the pressure force F p is calculated as pressure p(z) times the elemental membrane area wdz and the restoring force F r is calculated as the membrane stress σ m time the cross section of the membrane around both the rims 2dzt m (which is twice the membrane thickness t m time the elemental length dz). For small angles α, the sine is approximated as the tangent which is the slope of the membrane at its edges and can be found by calculating the derivative of the deflection curve at the rim of the membrane as ∂ (Δh)/ ∂y| y=w/2 = −4(Δh max)/w. Next, by solving for the pressure p(z), we get

The stress in the membrane wall (Fig. 12c) is a combination of residual stress σ 0 which may be already present when there is no deflection of the membrane and the stress σ d due to Hooke’s law generated by the deflection of the membrane (Schomburg 2011). Assuming zero residual stress in the membrane, we get

The stresses due to membrane deflection σ d can be calculated from the strains ɛ y and ɛ R in the transverse and radial directions, respectively (since, L ≫ w, the strain in the longitudinal direction is neglected). Now, according to Hooke’s law, the strains ɛ y and ɛ R can be expressed as

where ν m and E m denote Poisson’s ratio and Young’s modulus of the membrane, respectively. For thin membranes, transverse strain is assumed to be constant over the entire membrane (Schomburg 2011) which can be estimated by the extension of the membrane along the neutral fiber of the membrane. The length of the resulting parabola in the deflected state of the membrane is given as (Bronstein and Semendjajew 1976)

From the above expression of the extended length of the parabola and undeformed width of the membrane w and by using the assumption Δh max ≪ y 0, the transverse strain ɛ y can be obtained as

The fact that the radial strain is still unknown is resolved using one of the two assumptions (Schomburg 2011) (1) transverse and radial strains are equal throughout the membrane (2) transverse strain is zero throughout the membrane. The second assumption is invalid in the present case as the membrane has a deflection profile along the y-direction thus is subjected to nonzero transverse strain. Assuming that the tangential and radial strain are equal in magnitude throughout the membrane (transverse strain is tensile in nature but radial stress is compressive in nature, which results in ɛ R = −ɛ y ), from Eqs. 17 and 18, we get,

Finally, using Eqs. 15, 20 and 21, we get

By rearranging the terms in the above equation, we get the expression relating ∆h max with the pressure gradient across the membrane wall at the location, which is as follows.

Rights and permissions

About this article

Cite this article

Raj, A., Halder, R., Sajeesh, P. et al. Droplet generation in a microchannel with a controllable deformable wall. Microfluid Nanofluid 20, 102 (2016). https://doi.org/10.1007/s10404-016-1768-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10404-016-1768-4