Abstract

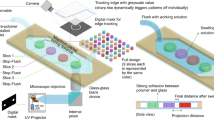

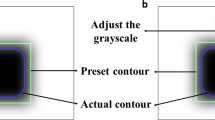

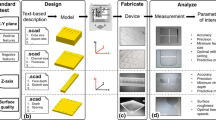

In this paper, we introduce computer-aided microfluidics (CAMF), a process that allows the creation of complex microfluidic structures from their concept to the actual chip within a day. During design and testing of new microfluidic systems, rapid and frequent design modifications have to be carried out. For this purpose, a device using maskless projection lithography based on a digital mirror device (DMD) has been developed. Digital mask layouts may be created using any graphics program (Microsoft Paint, Adobe Photoshop) and can be used as such by the custom-written control software of the system. However, we suggest using another approach: direct importing of three-dimensional digital computer-aided design (CAD) models from which mask information can be directly parsed. This process is advantageous as commercial 3D-CAD systems allow the rapid generation of static or parameterized models which can be used for computerized analyses like, e.g., flow simulation. After model validation, the mask information is extracted from these models and directly used by the lithography device. A chip or replication master is then created by means of lithography using curable monomers or resists as, e.g., Accura 60 or SU-8. With CAMF, the whole process from digital 3D model creation to actually running the experiment can be done within a day.

Similar content being viewed by others

References

Berthier E, Young EWK, Beebe D (2012) Engineers are from PDMS-land, Biologists are from Polystyrenia. Lab Chip 12(7):1224–1237

Cheng YL, Lee ML (2009) Development of dynamic masking rapid prototyping system for application in tissue engineering. Rapid Prototyp J 15(1):29–41. doi:10.1108/13552540910925045

Choi JW, Wicker R, Lee SH, Choi KH, Ha CS, Chung I (2009) Fabrication of 3D biocompatible/biodegradable micro-scaffolds using dynamic mask projection microstereolithography. J Mater Process Technol 209(15–16):5494–5503. doi:10.1016/j.jmatprotec.2009.05.004

de Mello A (2002) Plastic fantastic? Lab Chip 2(2):31N–36N. doi:10.1039/b203828p

Douglass MR (1998) Lifetime estimates and unique failure mechanisms of the Digital Micromirror Device (DMD). In: Reliability Physics Symposium Proceedings, 36th Annual. 1998 IEEE International, March 31–April 2 1998 pp 9–16. doi:10.1109/relphy.1998.670436

Duffy DC, McDonald JC, Schueller OJA, Whitesides GM (1998) Rapid prototyping of microfluidic systems in poly(dimethylsiloxane). Anal Chem 70(23):4974–4984. doi:10.1021/ac980656z

Haubert K, Drier T, Beebe D (2006) PDMS bonding by means of a portable, low-cost corona system. Lab Chip 6(12):1548–1549. doi:10.1039/b610567j

Hong CC, Choi JW, Ahn CH (2004) A novel in-plane passive microfluidic mixer with modified Tesla structures. Lab Chip 4(2):109–113. doi:10.1039/b305892a

Jo BH, Van Lerberghe LM, Motsegood KM, Beebe DJ (2000) Three-dimensional micro-channel fabrication in polydimethylsiloxane (PDMS) elastomer. J Microelectromech Syst 9(1):76–81. doi:10.1109/84.825780

Kattipparambil Rajan D, Lekkala J (2010) A maskless exposure device for rapid photolithographic prototyping of sensor and microstructure layouts. Proc Eng 5:331–334. doi:10.1016/j.proeng.2010.09.115

Keenan TM, Folch A (2008) Biomolecular gradients in cell culture systems. Lab Chip 8(1):34–57

Kitson PJ, Rosnes MH, Sans V, Dragone V, Cronin L (2012) Configurable 3D-Printed millifluidic and microfluidic ‘lab on a chip’ reactionware devices. Lab Chip 12(18):3267–3271

Lee K, Kim C, Ahn B, Panchapakesan R, Full AR, Nordee L, Kang JY, Oh KW (2009) Generalized serial dilution module for monotonic and arbitrary microfluidic gradient generators. Lab Chip 9(5):709–717. doi:10.1039/b813582g

Sia SK, Whitesides GM (2003) Microfluidic devices fabricated in poly(dimethylsiloxane) for biological studies. Electrophoresis 24(21):3563–3576. doi:10.1002/elps.200305584

Song YT, Noguchi M, Takatsuki K, Sekiguchi T, Mizuno J, Funatsu T, Shoji S, Tsunoda M (2012) Integration of pillar array columns into a gradient elution system for pressure-driven liquid chromatography. Anal Chem 84(11):4739–4745. doi:10.1021/ac3001836

Steigert J, Haeberle S, Brenner T, Mueller C, Steinert CP, Koltay P, Gottschlich N, Reinecke H, Ruehe J, Zengerle R, Ducree J (2007) Rapid prototyping of microfluidic chips in COC. J Micromech Microeng 17(2):333–341. doi:10.1088/0960-1317/17/2/020

Tan A, Rodgers K, Murrihy JP, O’Mathuna C, Glennon JD (2001) Rapid fabrication of microfluidic devices in poly(dimethylsiloxane) by photocopying. Lab Chip 1(1):7–9

Totsu K, Fujishiro K, Tanaka S, Esashi M (2006) Fabrication of three-dimensional microstructure using maskless gray-scale lithography. Sens Actuators A-Phys 130:387–392. doi:10.1016/j.sna.2005.12.008

Waldbaur A, Rapp H, Laenge K, Rapp BE (2011) Let there be chip-towards rapid prototyping of microfluidic devices: one-step manufacturing processes. Anal Methods 3(12):2681–2716. doi:10.1039/c1ay05253e

Waldbaur A, Waterkotte B, Schmitz K, Rapp BE (2012) Maskless projection lithography for the fast and flexible generation of grayscale protein patterns. Small 8(10):1570–1578. doi:10.1002/smll.201102163

Yang H, Ratchev S, Turitto M, Segal J (2009) Rapid manufacturing of non-assembly complex micro-devices by microstereolithography. Tsinghua Sci Technol 14(Supplement 1):164–167. doi:10.1016/s1007-0214(09)70086-0

Zhao SW, Cong HL, Pan TR (2009) Direct projection on dry-film photoresist (DP2): do-it-yourself three-dimensional polymer microfluidics. Lab Chip 9(8):1128–1132. doi:10.1039/b817925e

Acknowledgments

This work was supported in part by the ‘Concept for the Future’ of Karlsruhe Institute of Technology (KIT) within the framework of the German Excellence Initiative.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Waldbaur, A., Carneiro, B., Hettich, P. et al. Computer-aided microfluidics (CAMF): from digital 3D-CAD models to physical structures within a day. Microfluid Nanofluid 15, 625–635 (2013). https://doi.org/10.1007/s10404-013-1177-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10404-013-1177-x