Abstract

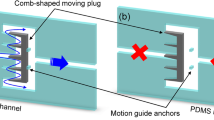

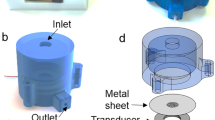

This study reports on a new pneumatic micropump integrated with a normally closed valve that is capable of generating a high pumping rate and a high back pressure. The micropump consists of a sample flow microchannel, three underlying pneumatic air chambers, resilient polydimethylsiloxane (PDMS) membrane structures and a normally closed valve. The normally closed valve of the micropump is a PDMS-based floating block structure located inside the sample flow microchannel, which is activated by hydraulic pressure created by the peristaltic motion of the PDMS membranes. The valve is used to effectively increase pumping rates and back pressures since it is utilized to prevent backflow. Experimental results indicate that a pumping rate as high as 900 μL/min at a driving frequency of 90 Hz and at an applied pressure of 20 psi (1.378 × 105 Nt/m2) can be obtained. The back pressure on the micropump can be as high as 85 cm-H2O (8,610.5 Nt/m2) at the same operation conditions. The micropump is fabricated by soft lithography processes and can be easily integrated with other microfluidic devices. To demonstrate its capability to prevent cross contamination during chemical analysis applications, two micropumps and a V-shape channel are integrated to perform a titration of two chemical solutions, specifically sodium hydroxide (NaOH) and benzoic acid (C6H5COOH). Experimental data show that mixing with a pH value ranging from 2.8 to 12.3 can be successfully titrated. The development of this micropump can be a promising approach for further biomedical and chemical analysis applications.

Similar content being viewed by others

Abbreviations

- CCD:

-

charge-coupled device

- C6H5COOH:

-

benzoic acid

- EMV:

-

electromagnetic valve

- MEMS:

-

micro-electro-mechanical-system

- NaOH:

-

sodium hydroxide

- PDMS:

-

polydimethylsiloxane

- pH:

-

power of hydrogen ions

- SEM:

-

scanning electron microscope

- UV:

-

ultraviolet

- μ-TAS:

-

micro-total-analysis-system

References

Ahn CH, Choi JW, Beaucage G, Nevin JH, Lee JB, Puntambekar A, Lee JY (2004) Disposable smart lab on a chip for point-of-care clinical diagnostics. Proc IEEE 92:154–173

Angell JB, Terry SC, Barth PW (1983) Silicon micromechanical devices. Sci Am 248:44–55

Auroux PA, Iossifidis D, Reyes DR, Manz A (2002) Micro total analysis systems: 2. Analytical standard operations and applications. Anal Chem 74:2637–2652

Baek JY, Park JY, Ju JI, Lee TS, Lee SH (2005) A pneumatically controllable flexible and polymeric microfluidic valve fabricated via in situ development. J Micromech Microeng 15:1015–1020

Baldi A, Gu Y, Loftness PE, Siegel RA, Ziaie B (2003) A hydrogel-actuated environmentally sensitive microvalve for active flow control. J Microelectromech Syst 12:613–621

Bourouina T, Bosseboeuf A, Grandchamp J (1997) Design and simulation of an electrostatic micropump for drug-delivery applications. J Micromech Microeng 7:186–188

Duffy DC, Schueller OJA, Brittain ST, Whitesides GM (1999) Rapid prototyping of microfluidic switches in poly(dimethyl siloxane) and their actuation by electro-osmotic flow. J Micromech Microeng 9:211–217

Feng GH, Kim ES (2004) Micropump based on PZT unimorph and one-way paralyne valves. J Micromech Microeng 14:429–435

Hosokawa K, Maeda R (2000) A pneumatically actuated three-way microvalve fabricated with polydimethylsiloxane using the membrane transfer technique. J Micromech Microeng 10:415–420

Hua Z, Xia Y, Srivannavit O, Rouillard JM, Zhou X, Gao X, Gulari E (2006) A versatile microreactor platform featuring a chemical-resistant microvalve array for addressable multiplex syntheses and assays. J Micromech Microeng 16:1433–1443

Huang CW, Huang SB, Lee GB (2006) Pneumatic micropumps with serially connected actuation chambers. J Micromech Microeng 16:2265–2272

Jeong OC, Konishi S (2007) Fabrication and drive test of pneumatic PDMS micro pump. Sens Actuators A 135:49–856

Koch M, Harris N, Evans A, White N, Brunnschweiler A (1998) A novel micromachined pump based on thick-film piezoelectric actuation. Sens Actuators A 70:98–103

Neagu CR, Gardeniers JGE, Elwenspoek M, Kelly JJ (1997) An electrochemical active valve. Electrochim Acta 42:3367–13

Ng TY, Jiang TY, Li H, Lam KY, Reddy JN (2004) A coupled field study on the non-linear dynamic characteristics of electrostatic micropump. J Sound Vib 273:989–1006

Nguyen NT, Truong TQ (2004) A fully polymeric micropump with piezoelectric actuator. Sens Actuators B 97:137–143

Paul BK, Terhaar T (2000) Comparison of two passive microvalve designs for microlamination architectures. J Micromech Microeng 10:15–20

Raiteri R, Grattarola M, Berger R (2002) Micromechanics senses biomolecules. Mater Today 5:22–29

Reyes DR, Iossifidis D, Auroux PA, Manz A (2002) Micro total analysis systems: 1. Introduction, theory, and technology. Anal Chem 74:2623–2636

Santra S, Hollaway P, Batich CD (2002) Fabrication and testing of a magnetically actuated micropump. Sens Actuators B 87:358–364

Sato K, Hibara A, Tokeshi M, Hisamoto H, Kitamori T (2003) Microchip-based chemical and biochemical analysis systems. J Chromatogr A 987:197–204

Sim WY, Yoon HJ, Jeong OC, Yang SS (2003) A phase-change type micropump with aluminum flap valves. J Micromech Microeng 13:286–294

Unger MA, Chou HP, Thorsen T, Scherer A, Quake SR (2000) Monolithic microfabricated valves and pumps by multilayer soft lithography. Science 288:113–116

Van de Pol FCM, Van Lintel HTG, Elwenspoek M, Fluitman JHJ (1990) Thermopneumatic micropump based on microengineering techniques. Sens Actuators A 21:198–202

Wang CH, Lee GB (2005) Automatic bio-sampling chips integrated with micropumps and microvalves for multiple disease detection. Biosens Bioelectron 21:419–425

Wang CH, Lee GB (2006) Pneumatically driven peristaltic micropumps utilizing serpentine-shape channels. J Micromech Microeng 16:341–348

Yamahata C, Lacharme F, Burri Y, Gijs MAM (2005) A ball valve micropump in glass fabricated by powder blasting. Sens Actuators B 110:1–7

Yang EH, Han SW, Yang SS (1996) Fabrication and testing of a pair of passive bivalvular microvalves composed of p + silicon diaphragms. Sens Actuators A 57:75–78

Zhang W, Ahn CH (1996) A bi-directional magnetic micropump on a silicon wafer. In: IEEE Solid-State Sensor and Actuator Workshop Technical Digest, pp 94–97

Acknowledgments

The authors gratefully acknowledge the financial support provided to this study by the National Science Council of Taiwan (NSC 96-2120-M-006-008).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, YN., Hsiung, SK. & Lee, GB. A pneumatic micropump incorporated with a normally closed valve capable of generating a high pumping rate and a high back pressure. Microfluid Nanofluid 6, 823–833 (2009). https://doi.org/10.1007/s10404-008-0356-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10404-008-0356-7