Abstract

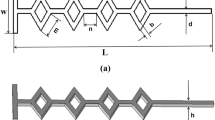

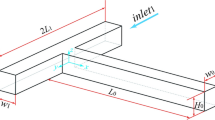

A planar micromixer with rhombic microchannels and a converging-diverging element has been proposed for its effective mixing. Both CFD-ACE numerical simulations and experiments were used to design and investigate the effect of three parameters (number of rhombi, turning angle and absence or presence of the converging-diverging element) on mixing. Mixing efficiency is dependent upon Reynolds number and geometrical parameters. Through the results of numerical simulation, it is evident that smaller turning angle (α), higher Reynolds number and increasing number of rhombi will result in better fluid mixing due to the occurrence of larger recirculation. The large recirculation is beneficial for both the increased interfacial contact area between two species and the convective mixing. In the numerical simulations, mixing efficiency of 99% was achieved with a most efficient system consisting of three-rhombus mixer with a converging-diverging element at α = 30° and Re = 200. An experimental mixing efficiency of about 94% has been obtained with the same design parameters. As expected, it is lower than the theoretical efficiency but is still very effective. A micromixer with such design can be potentially useful in the future applications of rapid and high throughput mixing.

Similar content being viewed by others

References

Bhaqat AS, Daqani G, Peterson ETK, Papautky L (2005) Passive micromixer with obstructions for Lab-on-a-chip applications In: Proceedings of SPIE microfluidics, BioMEMS, and medical microsystems conference, SPIE, vol 5718, pp 291–297

Bhaqat A, Peterson ET, Papautky L (2006) Passive micromixer with break-up obstructions In: Proceedings of SPIE microfluidics, BioMEMS, and medical microsystems conference, SPIE, vol 6112, 61120J

Bökenkamp D, Desai A, Yang X, Tai YC, Marzluff EM, Mayo SL (1998) Microfabricated silicon mixers for submillisecond quench-flow analysis. Anal Chem 70:232–236

Ducree J, Brenner T, Haeberle S, Glatzel T, Zengerle R (2006) Multilamination of flows in planar networks of rotating microchannels. Microfluid Nanofluid 2:78–84

Engler M, Föll C, Kockmann N, Woias P (2003) Investigations of liquid mixing in static micro mixers proceedings of the 11th European conference on mixing, pp 277–284

Gobby D, Ahgeli P, Gavriilidis A (2001) Mixing characteristics of T-type microfludic mixers. J Micromech Microeng 11:126–132

Hardt S, Drese KS, Hessel V, Schőnfeld F (2005) Passive micromixers for applications in the microreactor and μTAS fields. Microfluid Nanofluid 1:108–118

Howell PB, Mott DR, Golden JP, Ligler FS (2004) Design and evaluation of a Dean vortex-based micromixer. Lab Chip 4:663–669

Kim DS, Lee SW, Kwon TH, Lee SS (2004) A barrier embedded chaotic micromixer. J Micromech Microeng 14:798–805

Kockmann N, Föll C, Woias P (2003) Flow regimes and mass transfer characteristics in static micro mixers In: Proceedings of the SPIE photonics west, micromachining and microfabrication, SPIE, vol 4982, pp 319–329

Lee S, Lee HY, Lee IF, Tseng CY (2004) Ink diffusion in water. Eur J Phys 25:331–336

Lee SW, Kim DS, Lee SS, Kwon TH (2006) A split and recombination micromixer fabricated in a PDMS three-dimensional structure. J Micromech Microeng 16:1067–1072

Liu RH, Stremler MA, Sharp KV, Olson MG, Santiago JG, Adrian RJ, Aref H, Beebe DJ (2000) Passive mixing in a three-dimensional serpentine microchannel. J Microelectromech S 9:190–197

Löb P, Drese K S, Hessel V, Hardt S, Hofmann C, Löwe H, Schenk R, Schönfeld F, Werner B (2004) Steering of liquid mixing speed in interdigital micro mixers—from very fast to deliberately slow mixing. Chem Eng Technol 27:340–345

Lu LH, Ryu KS, Liu C (2002) A magnetic microstirrer and array for microfluidic mixing. J Microelectromech S 11:462–469

Mengeaud V, Josserand J, Girault HH (2002) Mixing processes in a zigzag microchannel: finite element simulations and optical study. Anal Chem 74:4279–4286

Schönfeld F, Hardt S (2004) Simulation of helical flows in microchannels. AIChE J 50:771–778

Schwesinger N, Frank T, Wurmus H (1996) A modular microfluid system with an integrated micromixer. J Micromech Microeng 6:99–102

Stroock AD, Dertinger SKW, Ajdari A, Mezic I, Stone HA, Whitesides GM (2002) Chaotic Mixer for Microchannels Science 295:647–651

Wang H, Lovenitti P, Masood S (2002) Optimizing layout of obstacles for enhanced mixing in microchannels. Smart Mater Struct 11:662–667

Wu Z, Nguyen N-T (2005) Convective–diffusive transport in parallel lamination micromixers. Microfluid Nanofluid 1:208–217

Acknowledgments

This work is partially sponsored by National Science Council (NSC) under contract No NSC 94-2212-E-006-055 and 95-2221-E-006-047-MY3. We would like to extend our great thanks to the Center for Micro/Nano Science and Technology (CMNST) at National Cheng Kung University and National Nano Device Laboratories (NDL) for the access of processing and analyzing equipments. We would also like to thank National Center for High-performing Computing (NCHC) for providing the computational fluid dynamics software in this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chung, C.K., Shih, T.R. Effect of geometry on fluid mixing of the rhombic micromixers. Microfluid Nanofluid 4, 419–425 (2008). https://doi.org/10.1007/s10404-007-0197-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10404-007-0197-9