Abstract

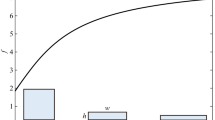

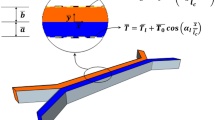

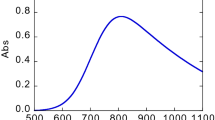

Pressure-driven transport of fluid and solute samples is often desirable in microfluidic devices, particularly where sufficient electroosmotic flow rates cannot be realized or the use of an electric field is restricted. Unfortunately, this mode of actuation also leads to hydrodynamic dispersion due to the inherent fluid shear in the system. While such dispersivity is known to scale with the square of the Peclet number based on the narrower dimension of the conduit (often the channel depth), the proportionality constant can vary significantly depending on its actual cross section. In this article, we review previous studies to understand the effect of commonly microfabricated channel cross sections on the Taylor–Aris dispersion of solute slugs in simple pressure-driven flow systems. We also analyze some recently proposed optimum designs which can reduce the contribution to this band broadening arising from the presence of the channel sidewalls. Finally, new simulation results have been presented in the last section of this paper which describe solutal spreading due to bowing of microchannels that can occur from stresses developed during their fabrication or operation under high-pressure conditions.

Similar content being viewed by others

References

Adamson AW (1990) Physical chemistry of surfaces. Wiley, New York

Alarie JP, Jacobson SC, Ramsey JM (2001) Electrophoretic injection bias in a microchip valving scheme. Electrophoresis 22:312–317

Aris R (1956) On the dispersion of a solute in a fluid flowing through a tube. Proc R Soc Lond 235A:67–77

Auroux PA, Iossifidis D, Reyes DR, Manz A (2002) Micro total analysis systems. 2. Analytical standard operations and applications. Anal Chem 74(12):2637–2652

Balakotaiah V, Chang HC (1995) Dispersion of chemical solutes in chromatographs and reactors. Philos Trans R Soc Lond A 351:39–75

Becker H, Locascio LE (2002) Polymer microfluidic devices. Talanta 56:267–287

Brenner H, Edwards DA (1993) Macrotransport processes. Butterworth-Heinemann, Boston

Chang DC, Chassy BM, Saunders JA, Sowers AE (eds) (1992) Guide to electroporation and electrofusion. Academic, San Diego

Chatwin PC, Sullivan PJ (1982) The effect of aspect ratio on longitudinal diffusivity in rectangular channels. J Fluid Mech 120:347–358

Desmet G, Baron GV (2002) Chromatographic explanation for the side-wall induced band broadening in pressure-driven and shear-driven flows through channels with a high aspect-ratio rectangular cross section. J Chromatogr A 946:51–58

Doshi MR, Daiya PM, Gill WN (1978) 3 dimensional laminar dispersion in open and closed rectangular conduits. Chem Eng Sci 33:795–804

Dougherty AM (1997) Handbook of capillary electrophoresis. In: Landers JP (ed) CRC Press, Boca Raton, FL

Dutta D, Leighton DT (2001) Dispersion reduction in pressure-driven flow through microetched channels. Anal Chem 73:504–513

Dutta D, Leighton DT (2003a) Dispersion in large aspect ratio microchannels for open-channel liquid chromatography. Anal Chem 75:57–70

Dutta D, Leighton DT (2003b) Dispersion reduction in open-channel liquid electrochromatographic columns via pressure-driven back flow. Anal Chem 75:3352–3359

Fiorini GS, Chiu DT (2005) Disposable microfluidic devices: fabrication, function and application. Biotechniques 38:429–446

Gas B, Kenndler E (2000) Dispersive phenomena in electromigration separation methods. Electrophoresis 21:3888–3897

Gas B, Kenndler E (2002) Peak broadening in microchip electrophoresis: a discussion of the theoretical background. Electrophoresis 23:3817–3826

Gill WN, Sankarasubramanian R (1970) Exact analysis of unsteady convective diffusion. Proc R Soc Lond A 316 :341–350

Golay MJE (1981) The height equivalent to a theoretical plate of retentionless rectangular tubes. J Chromatogr 216:1–8

Grushka E, McCormick RM, Kirkland JJ (1989) Effect of temperature-gradients on the efficiency of capillary zone electrophoresis separations. Anal Chem 61:241–246

Guell DC, Cox RG, Brenner H (1987) Taylor dispersion in conduits of large aspect ratio. Chem Eng Comm 58:231–244

Hao PF, He F, Zhu KQ (2005) Flow characteristics in a trapezoidal silicon microchannel. J Micromech Microeng 15:1362–1368

Herr AE, Molho JI, Santiago JG, Mungal MG, Kenny TW (2000) Electroosmotic capillary flow with non-uniform zeta potential. Anal Chem 72:1053–1057

Holden MA, Kumar S, Beskok A, Cremer PS (2003) Microfluidic diffusion diluter: bulging of PDMS microchannels under pressure-driven flow. J Micromech Microeng 13:412–418

Kirby BJ, Hasselbrink EF (2004a) Zeta potential of microfluidic substrates: 1. Theory, experimental techniques, and effects on separations. Electrophoresis 25(2):187–202

Kirby BJ, Hasselbrink EF (2004b) Zeta potential of microfluidic substrates: 2. Data for polymers. Electrophoresis 25(2):203–213

Koutny LB, Schmalzing D, Taylor TA, Fuchs M (1996) Microchip electrophoretic immunoassay for serum cortisol. Anal Chem 68:18–22

Laser DJ, Santiago JG (2004) A review of micropumps. J Micromech Microeng 14(6):R35-R64

Li Y, Xiang R, Wilkins JA, Honrath C (2004) Capillary electrochromatography of peptides and proteins. Electrophoresis 25(14):2242–2256

Lin CC, Chen CC, Lin CE, Chen SH (2004) Microchip electrophoresis with hydrodynamic injection and waste removing function for quantitative analysis. J Chromatogr A 1051:69–74

Madou MJ (2002) Fundamentals of microfabrication: the science of miniaturization, 2nd edn. CRC Press, Boca Raton

Manz A, Graber N, Widmer HM (1990) Miniaturized total chemical analysis systems—a novel concept for chemical sensing. Sens Actuators 81:244–248

McClain MA, Culbertson CT, Jacobson SC, Allbritton NL, Sims CE, Ramsey JM (2003) Microfluidic devices for the high-throughput chemical analysis of cells. Anal Chem 75(21):5646–5655

Nguyen NT, Huang XY, Chuan TK (2002) MEMS micropumps: a review. J Fluid Eng-T ASME 124(2):384–392

Pagitsas M, Nadim A, Brenner H (1986) Multiple time scale analysis of macrotransport processes. Phys A 135:533–550

Park H, Pak JJ, Son SY, Lim G and Song I (2003) Fabrication of a microchannel integrated with inner sensors and the analysis of its laminar flow characteristics. Sens Actuators A 103:317–329

Qu WL, Mala GM, Li DQ (2000) Pressure-driven water flows in trapezoidal silicon microchannels. Int J Heat Mass Transfer 43:353–364

Rai-Choudhury P (1997a) Handbook of microlithography, micromachining and microfabrication, vol 1, 1st edn. SPIE Press, Bellingham

Rai-Choudhury P (1997b) Handbook of microlithography, micromachining and microfabrication, vol 2, 1st edn. SPIE Press, Bellingham

Reyes DR, Iossifidis D, Auroux PA, Manz A (2002) Micro total analysis systems. 1. Introduction, theory and technology. Anal Chem 74(12):2623–2636

Sanders GHW, Manz A (2000) Chip-based microsystems for genomic and proteomic analysis. Trends Anal Chem 19:364–378

Schomburg G (1998) High performance capillary electrophoresis: theory, techniques and applications, vol 146, 1st edn. In: Khaledi MG (ed) Wiley-Interscience, NewYork

Shih WP, Hui CY, Tien NC (2004) Collapse of microchannels during anodic bonding: theory and experiments. J Appl Phys 95:2800–2808

Sia SK, Whitesides GM (2003) Microfluidic devices fabricated in poly(dimethylsiloxane) for biological studies. Electrophoresis 24:3563–3576

Taylor GI (1953) Dispersion of soluble matter in solvent flowing slowly through a tube. Proc R Soc Lond 219A:186–203

Vilkner T, Janasek D, Manz A (2004) Micro total analysis systems: recent developments. Anal Chem 76(12):3373–3385

Woias P (2005) Micropumps—past, progress and future prospects. Sens Actuators B 105(1):28–38

Wooding RA (1960) Instability of a viscous liquid of variable density in a vertical Hele-Shaw cell, J Fluid Mech 7:501–515

Wu HY, Cheng P (2003) Friction factors in smooth trapezoidal silicon microchannels with different ratios. Int J Heat Mass Transfer 46:2519–2525

Xuan XC, Xu B, Sinton D, Li DQ (2004) Electroosmotic flow with Joule heating effects. Lab Chip 4:230–236

Zholkovskij EK, Masliyah JH (2004) Hydrodynamic dispersion due to combined pressure-driven and electroosmotic flow through microchannels with a thin double layer. Anal Chem 76:2708–2718

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dutta, D., Ramachandran, A. & Leighton, D.T. Effect of channel geometry on solute dispersion in pressure-driven microfluidic systems. Microfluid Nanofluid 2, 275–290 (2006). https://doi.org/10.1007/s10404-005-0070-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10404-005-0070-7