Abstract

Bacterial response to environmental stimuli is essential for survival. In response to fluctuating environmental conditions, the physiological status of bacteria can change due to the actions of transcriptional regulatory machinery. The synthesis and accumulation of polyhydroxyalkanoates (PHAs) are one of the survival strategies in harsh environments. In this study, we used transcriptome analysis of Pseudomonas putida KT2440 to gain a genome-wide view of the mechanisms of environmental-friendly biopolymers accumulation under nitrogen-limiting conditions during conversion of metabolically different carbon sources (sodium gluconate and oleic acid). Transcriptomic data revealed that phaG expression is associated with medium-chain-length-PHAs’ synthesis not only on sodium gluconate but also on oleic acid, suggesting that PhaG may play a role in this process, as well. Moreover, genes involved in the β-oxidation pathway were induced in the PHAs production phase when sodium gluconate was supplied as the only carbon and energy source. The transition from exponential growth to stationary phase caused a significant expression of genes involved in nitrogen metabolism, energy supply, and transport system. In this study, several molecular mechanisms, which drive mcl-PHAs synthesis, have been investigated. The identified genes may provide valuable information to improve the efficiency of this bioprocess and make it more economically feasible.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Bacterial survival requires the ability to sense and respond to fluctuating environmental conditions. To sustain growth, microorganisms must constantly cope with upcoming challenges, especially alterations in nutrient availability. Cellular stress response to nitrogen starvation is a complex process that not only affects microbial existence but also influences the productivity of some metabolic products such as polyhydroxyalkanoates [18].

Polyhydroxyalkanoates (PHAs) are bacterial storage compounds produced by many microorganisms under growth-limiting conditions, such as a nitrogen, phosphorus, or oxygen starvation, and when an excess of a carbon source is available in the environment. These biopolymers continue to attract increasing industrial interest as a renewable, biodegradable, biocompatible thermoplastics being considered as a replacement for hazardous petrochemical polymers. Several reviews have described their potential applications [2, 6, 7]. The main groups of PHAs are short-chain-length PHAs (scl-PHAs) with five or less carbon atoms, and medium-chain-length PHAs (mcl-PHAs) with six or more carbon atoms. Scl-PHAs synthesis is a common feature of many microorganisms, whereas mcl-PHAs have been observed mainly in fluorescent and non-fluorescent Pseudomonas species. Mcl-PHAs could consist of 3-hydroxyhexanoate (3HHx), 3-hydroxyoctanoate (3HO), 3-hydroxydecanoate (3HD), 3-hydroxydodecanoate (3HDD), 3-hydroxytetradecanoate (3HTD), or even higher chain length monomers, and appear to be much more elastomeric and resistant than scl-PHAs [29, 45]. It is well known that the monomeric composition of PHAs varies depending on the producing organism and on the available carbon source [34, 35].

PHA-producing microorganisms are able to link carbon catabolic pathways together with PHA anabolic pathways, which makes this microorganisms specialized cell factories that can produce PHAs from various carbon sources [46]. These potential carbon sources are saccharides, n-alkanes, n-alkanoic acids, n-alcohols, and various gases (e.g., methane and carbon dioxide). Depending on the type of carbon source, bacteria generally use one of two central pathways for (R)-3-hydroxyacyl-CoA generation, either β-oxidation or fatty acid de novo synthesis. β-Oxidation is used when fatty acids and alkanoic acids are used as carbon sources. In contrast, the fatty acid de novo synthesis pathway converts structurally non-related carbon sources, such as glucose, glycerol, gluconate, acetate, or ethanol [22]. The fatty acid de novo biosynthesis pathway is linked with PHA biosynthesis by the phaG gene. This gene codes for transacylase, which catalyzes the transfer of the (R)-3-hydroxydecanoyl moiety from acyl carrier protein to CoA [21].

The PHA biosynthesis gene cluster of Pseudomonas species comprises four genes that encode two PHA synthases (phaC1 and phaC2), an intracellular depolymerase (phaZ) and a transcriptional regulator (phaD) [25]. Another gene cluster, containing the genes encoding the PHA granule-associated proteins phaF and phaI, believed to be involved in PHAs biosynthesis regulation, is located downstream of the PHAs synthesis gene cluster and is transcribed in the opposite direction [41]. The phaG gene mentioned above is not co-localized with other pha genes [20]. Although the key genes engaged in the mcl-PHAs biosynthesis are known, knowledge on the regulatory mechanisms at the transcriptomic level during mcl-PHAs synthesis under nitrogen starvation is limited. Advances in next-generation sequencing technologies provide new opportunities for finding information on microbial physiology and metabolic pathways that can be essential from the industrial point of view. Pseudomonas putida KT2440 has gained much attention in recent years as a metabolically versatile bacterium which has become an efficient cell factory for the production of value-added compounds [38]. Its versatility, degradative potential, and capacity to use a wide range of carbon sources make this bacterium an extraordinary candidate for industrial application. P. putida KT2440 has been used many times for mcl-PHAs production using different carbon sources. In addition, the molecular background of mcl-PHAs synthesis has been investigated in many studies so far, providing valuable information about the metabolic pathways leading to mcl-PHAs synthesis, the genes coding for the enzymes that are the engines of these conversion pathways (reviewed in [40]), and the molecular regulation of these transformations (reviewed in [28]). However, the overall picture of the molecular mechanisms related to mcl-PHAs synthesis is not clear. In particular, there is a lack of information about differences at the transcriptomic level when different carbon sources are used, and this knowledge could be useful for understanding the intricacies of carbon metabolism in P. putida KT2440 under nutrient starvation. Therefore, this study compared the transcriptomes of P. putida KT2440 during conversion of different carbon sources that require the use of either the de novo fatty acid synthesis pathway (sodium gluconate) or the β-oxidation pathway (oleic acid). The metabolic response of P. putida KT2440 to nitrogen-limiting conditions and a potential mechanism of global regulation are discussed.

Materials and methods

Growth conditions

Pseudomonas putida KT2440 (ATCC® 47054™) was grown in a nitrogen-limited mineral medium consisting of (per liter): 2 g Na2HPO4·12H2O, 2 g KCl, 0.3 g Na2SO4, 1 g (NH4)SO4, 1 g MgSO4·7H2O, and 2.5 mL of trace element solution. Each liter of trace element solution contained: 20 g FeCl3·6H2O, 10 g CaCl2·H2O, 0.03 g CuSO4·5H2O, 0.05 g MnCl2·4H2O, and 0.1 g ZnSO4·7H2O dissolved in 0.5 N HCl. The cultures were supplemented with sodium gluconate or oleic acid as the only substrate in the same carbon concentration (3.8 g/L) in the production media. The cultivation was carried out in a 5 L working volume in a bioreactor (BioFlo 110, New Brunswick Scientific) at 30 °C with an aeration rate of 4 L/min. pH value was maintained at 7 through the modulated addition of concentrated 1 N NaOH and 1 N HCl. The dissolved oxygen was monitored during the whole cycle with O2 electrode (InPro 6800, Mettler Toledo GmbH, Switzerland) and maintained 50% air saturation by adjusting the agitation rate from 300 to 1000 rpm automatically. A concentrate solution (Sigma-Aldrich, USA) was used as antifoam in response to the antifoam controller. Total fermentation time was 48 h. In addition, parameters such as biomass, mcl-PHA, nitrogen, and phosphorus concentrations were controlled during the experiments.

Analytical methods

The bacterial cell density was monitored as absorbance at 600 nm (OD600) with a spectrophotometer. During the fermentation, samples of the culture broth were taken for analysis at 8, 17, 24, 32, 41, and 48 h for measurements of cell dry weight, mcl-PHAs accumulation, and ammonium/phosphorus concentration, and for determination of monomers composition and their concentrations. Cell dry weight (CDW) was determined by centrifuging 100 mL culture broth at 11,200×g for 10 min. The collected cells were then weighed after lyophilization. The lyophilization process was performed by Lyovac GT2 System (SRK Systemtechnik GmbH) for 24 h. Ammonium and phosphorus concentration was measured spectrophotometrically using the Hach Lange DR 2800 spectrophotometer (Hach Lange, Düsseldorf DE) and the LCK303 kit for ammonium and LCK350 kit for phosphorus according to the manufacturer’s instructions.

Mcl-PHAs were extracted from lyophilized cells using the chloroform/methanol procedure for quantitative and qualitative analysis. These biopolyesters were extracted by shaking of the freeze-dried cells in chloroform at 50 °C for 3 h. The mixture was filtered through No. 1 Whatman filter paper by simple filtration and then precipitated with four volumes of 70% solution of chilled methanol and then allowed to evaporate for at room temperature. The monomeric composition of the purified mcl-PHAs was determined using a methanolysis protocol as described previously [33]. The concentrations of methyl esters were estimated by a gas chromatography (GC) equipped with a capillary column Varian VF-5 ms with a film thickness of 0.25 μm (Varian, Lake Forest, USA). Pure standards of methyl 3-hydroxyhexanoate, -octanoate, -nonanoate, -decanoate, -undecanoate, -dodecanoate, -tetradecanoate, and -hexadecanoate were used to generate calibration curves for the methanolysis assay. All samples were analyzed in triplicates.

RNA extraction

Total RNA was extracted from the RNALater™-preserved bacterial cells using a commercial RNA extraction Kit (A&A Biotechnology, Poland) according to the manufacturer’s instructions. Total RNA was eluted with 50 μL of RNase-free water and contaminating DNA was removed via the On-Column DNase I Digest Set (Sigma-Aldrich, USA). Each time, the absence of contaminating DNA was proven by PCR reaction. The RNA concentration and purity were determined using a Bioanalyzer with the RNA 6000 Nano Assay (Agilent Technologies, Santa Clara, CA) according to the manufacturer’s protocol. The RNA integrity number (RIN) of every RNA sample used for sequencing was higher than 8.0. Samples for Illumina sequencing were collected for RNA isolation at 24 and 41 h of the fermentation, with each time corresponding to a different growth phase.

Library preparation, Illumina sequencing, and RNAseq data analysis

RNAseq template libraries were constructed with 1 μg of the enriched mRNA samples using Truseq RNA Sample Preparation Kit (Illumina, California, USA) through a four-step protocol of end repairing, adding adenylate 3′ ends, adapter ligation, and cDNA template enrichment. Deep sequencing was performed by Illumina HiSeq 2500 according to the manufacturer’s instruction with a read length of 1 × 50 nucleotides. Raw data were pre-processed using FASTX-Toolkit (version 0.0.13) to remove low-quality sequences and adaptors. Clean RNAseq reads were aligned to the corresponding Pseudomonas putida KT2440 genome, which were revisited previously using Bowtie with the default parameters [4]. Genome sequences and annotation data of P. putida KT2440 were downloaded from NCBI (downloaded on 20 April, 2017). The reads that mapped to rRNA and tRNA sequences were excluded from further analysis. The reads per gene values of all genes were calculated from the SAM output files. Testing for differential expression was performed with DESeq package that uses a statistical model based on the negative binomial distribution [1]. Significant differential expressed genes with a false discovery rate (FDR value) of < 0.05 and a fold change of > 2 were selected for further analysis. The raw RNAseq data were deposited to the NCBI Sequence Read Archive (SRA) database with BioProject accession: SAMN06553737, SAMN06553738, SAMN06553739, and SAMN06553740.

Real-time quantitative PCR (qPCR)

RNAseq data were confirmed by examining the expression of phaC1, phaC2, phaZ, phaD, phaI, phaF, and phaG genes by qRT-PCR. Total RNA was extracted as described above. The cDNA was performed using a SuperScript Vilo™ cDNA Synthesis Kit (Invitrogen) according to the manufacturer’s protocol. The synthesized first-strand cDNA was directly used as the template for qRT-PCR using SYBR Green technology in an ABI 7500 real-time PCR system (Applied Biosystems, USA) in MicroAmpTM Optical 96-well reaction plates (Applied Biosystems, USA). The primer pairs used for real-time amplification were described previously [36]. Standard curves using primer sets for pha genes were amplified against various concentrations of Pseudomonas putida KT2440 genomic DNA (from 5 × 10−7 to 5 ng). The reactions were run using the thermal cycling parameters as follows: 95 °C for 3 min, then 40 cycles of 95 °C for 15 s, and 60 °C for 1 min. After performing a run, a final standard melting curve stage was included. In each run, negative controls (no cDNA) for each primer set were included.

Results

Growth and mcl-PHAs synthesis

To show differences in mcl-PHAs synthesis by Pseudomonas putida KT2440, two fermentation batches, supplemented with metabolically different carbon sources, were conducted. The bacterial cells were grown in a nitrogen-limited mineral salt medium containing sodium gluconate or oleic acid as the only carbon source.

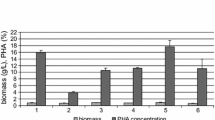

As shown in Fig. 1, the Pseudomonas putida KT2440 cells initially grew without accumulating PHAs. The bacteria growing on sodium gluconate and oleic acid started to synthesize mcl-PHAs after 8 h of the fermentation. However, the level of mcl-PHAs in bacterial cells was higher with sodium gluconate. With sodium gluconate in the medium, ammonium was completely consumed during the first 17 h of the bioprocess. When the nitrogen source was depleted, the amount of mcl-PHAs value started to increase rapidly from 5.34% (at 17 h) to 17.02% (at 41 h) of cell dry weight (CDW). Then, the content of these biopolymers decreased, reaching 13.32% at the end of cultivation. Pseudomonas putida KT2440 accumulated less mcl-PHAs when cultivated on oleic acid (2.34% of CDW at 17 h and 9.86% of CDW at 48 h) than when cultivated on sodium gluconate. In the oleic acid variant, the bacteria took 41 h to deplete the entire amount of nitrogen. However, as initially desired, the biomass was similar in both cultivations. In both variants, at 24 h, Pseudomonas putida KT2440 was in the exponential phase and at 41 h of cultivation in the stationary phase (Fig. 2). In both experimental conditions, only the nitrogen stress was observed, and phosphate concentrations did not appear to be limiting factors. During both fermentations, phosphorus concentrations only slightly decreased throughout the entire process.

Growth during fermentation cultures of Pseudomonas putida KT2440 grown on sodium gluconate (a) or oleic acid (b). Numbers in parenthesis indicate the sampling time of biomass for total RNA isolation used for RNAseq analysis. (1) and (2) indicate samples collected at 24 and 41 h of the cultivation, respectively

The composition of the extracted and purified mcl-PHAs was determined by GC of the 3-hydroxyalkanoates methyl esters. The biopolyesters was found to consist mainly of 3-hydroxyoctanoate and 3-hydroxydecanoate, lesser amounts of 3-hydroxydodecanoate, and trace amounts of 3-hydroxyhexanoate. 3-hydroxytetradecanoate was found in low amounts in mcl-PHAs obtained from P. putida KT2440 cultivated on sodium gluconate (Table 1). The major repeat units were similar to those produced by other Pseudomonas species cultivated on related and non-related carbon sources [9, 10].

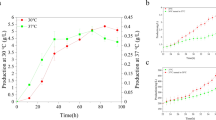

Expression levels of mcl-PHAs biosynthetic genes

The expression levels of phaC1, phaC2, phaZ, phaD, phaI, phaF, and phaG genes were monitored by reverse transcription real-time PCR. As can be seen in Fig. 3, the mRNA copy numbers differed between the types of substrate. During the fermentation with sodium gluconate, the transcript numbers of the investigated genes were highest at 24 h of fermentation, when ammonium was completely consumed. After this, they declined up until the end of fermentation. When oleic acid was used, the nitrogen depletion (after 32 h) induced mainly the expression of phaF and phaG genes. With both carbon sources, the transcript numbers of the phaI and phaF genes were much higher than those of the other genes involved in mcl-PHAs synthesis. The profile of phaF, phaI, and phaG expression differed depending on the substrate that was used. With sodium gluconate, their expression was higher at 24 and 32 h than at other times. With oleic acid, the expression of these genes reached the highest level at 41 h. With sodium gluconate, the changes in transcription over time of all pha genes were similar. Furthermore, during the fermentation with sodium gluconate, all pha genes had lower expression at 41 h than at 24 h, whereas these genes had higher expression with oleic acid at that time period.

Overview of transcriptomic analysis

A total of about 150-million raw sequencing reads were generated from RNAseq data using the Illumina platform, with an average of 37.5 million reads per sample. After the elimination of low-quality reads with multiple N, reads shorter than 20 bp, and removal of sequences coding for rRNA, a total of 119 million qualified mRNA sequence reads were mapped onto the Pseudomonas putida KT2440 genome. After expression quantification, differential gene expression analysis was carried out between samples collected at 24 and 41 h of the cultivation with both carbon sources, as these time corresponded to a different cellular phases (exponential and stationary). The expression levels for each gene were quantified as reads per kilobase per million mapped reads (RPKM), as described by Mortazavi et al. [32].

The DESeq analysis led to identification of 60 and 61 genes for sodium gluconate and oleic acid, respectively, whose expression differed significantly (p < 0.05) between 24 and 41 h. With sodium gluconate, 16 differentially expressed genes were up-regulated with fold changes ranging from 6.2 to 65.3 (Supplementary material S1). With oleic acid, interestingly, most genes (53 genes) were up-regulated with fold changes from 4.7 to 818.8 (Supplementary material S2). In general, 19 genes were significantly differentially expressed at both analyzed time-points in both cultivations, while 41 genes and 42 genes were specifically induced in Pseudomonas putida KT2440 cultivated on sodium gluconate or oleic acid, respectively (Fig. 4).

Number of significantly differentially expressed genes in bacterial cells growing on sodium gluconate and oleic acid towards mcl-PHAs synthesis. a Number of up-regulated and down-regulated genes between samples at 24 and 41 h of the cultivation. b Venn diagram showing the numbers of common and specific DEGs in samples with metabolically different substrates

The RNAseq data provide detailed information about the genes that are regulated (induced or suppressed) in response to nitrogen starvation during mcl-PHAs synthesis. The differentially expressed genes were sorted into role categories to evaluate which functions could be related to mcl-PHAs biosynthesis process during cultivation on the two different carbon sources (sodium gluconate or oleic acid). In the biological ontology, we found that the most abundant terms were transport and metabolic processes. In the cellular component, integral component of membrane was the dominant term with both substrates, and in the molecular function ontology, binding and catalytic activity terms were dominant (Fig. 5). Furthermore, pathway analyses were used to identify the significant pathways associated with the differentially expressed genes according to KEGG. With sodium gluconate, the up-regulated genes were mainly involved in the citrate cycle (TCA cycle), glycolysis/gluconeogenesis, pyruvate metabolism, microbial metabolism in diverse environments, biosynthesis of secondary metabolites, and carbon metabolism. In particular, the transcript levels of genes encoded by PP_2858, PP_2855, PP_4057, and those involved in acetoin metabolism (acoA, acoB, and acoC) were elevated, whereas those involved in the pentose-phosphate pathway, ABC transporters, nitrogen metabolism, and two-component systems were down-regulated. The gene encoding Xaa-Pro aminopeptidase (PP_4752), syringomycin biosynthesis protein 2 (PP_3783), and gluconate 2-dehydrogenase gamma subunit (PP_3384) were the most significantly down-regulated. When cultivations were supplemented with oleic acid, the up-regulated genes of Pseudomonas putida KT2440 were found to be involved in nitrogen metabolism, arginine biosynthesis, microbial metabolism in diverse environments, purine metabolism, and ABC transporters. The pathways in which the down-regulated genes could be involved were not identified; for the most part, these genes encode hypothetical proteins. With both carbon sources, the following genes were significantly differentially expressed during mcl-PHAs synthesis: genes involved in nitrogen metabolism (nirB, nirD, and nasA), microbial metabolism in diverse environments (ureA and ureB), ABC transporters (urtB, urtC, and urtD), and two-component system response regulator NasT (PP_2093).

With regard to carbon source metabolism (Fig. 6), the data suggest that the expression level of genes involved in the Entner–Doudoroff pathway, pyruvate metabolism, fatty acid de novo synthesis, and β-oxidation pathway could have an effect on increased mcl-PHAs synthesis. Pseudomonas putida KT2440 grown on sodium gluconate accumulated about 1.5 times more mcl-PHAs at 41 h of the fermentation than at 24 h. During this cultivation, all genes engaged in above-mentioned metabolic pathways had lower expression at 41 h than at 24 h, except for the acoA, acoB, and acoC genes, which were significantly up-regulated. To evaluate the effect of these genes on biopolymers production, we collected samples at the same time-points from the bioreactor supplemented with oleic acid. In this cultivation, mcl-PHAs concentration remained the same (about 7% of CDW at 24 and 41 h). In addition, expression of the acoA, acoB, and acoC genes did not change significantly. Furthermore, the expression of genes related to the synthesis of malonyl-CoA from acetyl-CoA seems to be dependent on the carbon source that is used. At 24 h, the expression of accA, accB, accC, and accD genes was the highest in P. putida KT2440 cultivated on sodium gluconate, and these values were about threefold higher than in the same culture at 41 h. A similar trend was noted during cultivation with oleic acid, although the decrease in expression over time was smaller, especially for accB and accD gene, which were 1.5-fold and 0.1-fold lower at 41 h, respectively. When comparing the two substrates, the expression of each of these genes at each time point was at least threefold lower with sodium gluconate than with oleic acid. The genes fabF, fabB, fabZ, and PP_4635, which are involved in de novo fatty acid synthesis, were highly expressed at 24 h, except for fabG and acpP which expression was on the same or slightly higher level at 41 h compared to the growth phase. Furthermore, the genes related to β-oxidation pathway were expressed also in the cultivation with sodium gluconate as the only substrate. Their expression levels were similar to the transcripts abundance observed in the fermentation with oleic acid.

Changes in the expression of genes involved in central pathways for (R)-3-hydroxyacyl-CoA generation in P. putida KT2440 affected by growth on sodium gluconate or oleic acid under nitrogen stressful conditions. SG24-sodium gluconate‚ 24 h of the cultivation; SG41-sodium gluconate‚ 41 h of the cultivation; OA24-oleic acid‚ 24 h of the cultivation; OA41-oleic acid‚ 41 h of the cultivation

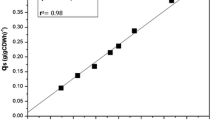

Validation of Illumina sequence data using qRT-PCR

To confirm the data obtained by RNAseq, the expression of the most important genes for mcl-PHAs synthesis (phaC1, phaZ, phaC2, phaD, phaI, phaF, and phaG) was determined with real-time quantitative PCR (qPCR). The qPCR results of the majority of analyzed genes were in good agreement with the RNAseq data indicating the high credibility of these genes in transcript abundance suggesting a good quality of RNAseq data. In a case of phaC1, phaI, and phaF genes, the discrepancies in the fold-change level between RNAseq and qPCR were observed, but still the trend in the changes of their expression profiles was the same (Table 2).

Discussion

Bacterial adaptation to nutrient limitation is of interest not only because it enables the bacteria to survive in harsh environments, but also because it can induce valuable bioproducts’ production. The mechanism involved in the regulation of mcl-PHAs synthesis at the transcriptional level seems to be important, and thus, great effort is being made to detect genes potentially involved in this bioprocess. The investigation of molecular mechanisms that drive mcl-PHAs synthesis may provide valuable information to improve the efficiency of this bioprocess and make it more economically feasible.

This study used RNAseq technologies to examine and compare the transcriptomes of Pseudomonas putida KT2440 cultivated on two metabolically different carbon sources. In general, the presented results indicated the difference in the transcriptional response to nitrogen limitation during microbial mcl-PHAs synthesis. Although Pseudomonas putida KT2440 has been used as a model microorganism in different studies including those looking at molecular machinery [5, 8, 13, 39], its nitrogen and substrate response transcriptome has not yet been analyzed and compared. To better understand the process, a time course study of the Pseudomonas putida KT2440 response transcriptome was carried out.

The data confirm that Pseudomonas putida KT2440 was able to synthesis mcl-PHAs under the applied conditions. Among pha cluster genes, phaF and phaI genes showed the highest expression levels and the trend of their expression changes was similar. It has been suggested that PhaF and PhaI phasins play a crucial role in PHAs granule formation and localization [15]. In our study, the highest mcl-PHAs content in bacterial cells growing on both substrates was proceeded by the highest levels of phaF and phaI transcripts. It could be suggested that the overproduction of pha genes, especially PhaI and PhaF phasins, could improve mcl-PHAs biosynthesis process. Similar behaviour in transcription showed phaG gene coding for 3-hydroxyacyl-ACP:CoA transacylase-linking fatty acids de novo synthesis and biosynthesis of medium-chain-length polyhydroxyalkanoates [42, 44]. PhaG was reported to be important for synthesizing mcl-PHAs from non-related carbon sources such as gluconate and glucose [19]. Our results add to these findings by showing that phaG expression is associated with mcl-PHAs synthesis on oleic acid (a structurally related carbon source), suggesting that PhaG may play a role in this process, as well. An association between increased phaG expression and mcl-PHAs synthesis on oleic acid was also found in our previous work using the P. putida KT2440 relA/spoT mutant [36]. Our results also confirm that the expression level of pha cluster genes and the concentration of mcl-PHAs that are accumulated are strongly correlated.

There are several metabolic routes that could be involved in the synthesis of 3-hydroxyacyl-CoA thioesters. On non-related carbon sources like gluconate or glycerol, fatty acid de novo synthesis is active during growth, but when a cultivation is supplemented with fatty acids as a substrate, β-oxidation is the main pathway. The first step of fatty acid biosynthesis, the synthesis of malonyl-CoA from acetyl-CoA, is catalyzed by acetyl-CoA carboxylase (ACC). ACC is composed of four distinct proteins; biotin carboxyl carrier protein (AccB), biotin carboxylase (AccC), and two subunits each of ACCase subunit alpha (AccA) and ACCase subunit beta (AccD). The conversion of acetyl-CoA to malonyl-CoA takes place in distinct partial reactions. The first step is the transfer of CO2 in an ATP-dependent fashion from bicarbonate to the biotin moiety of AccB, resulting in carboxybiotinoyl-AccB. In the second step, the CO2 group is subsequently transferred from carboxybiotin to acetyl-CoA to form malonyl-CoA [11]. Since acetyl-CoA carboxylase catalyzes the initial step of fatty acid biosynthesis, it has been the subject of very intensive study. In particular, ACC could be important in the PHA synthesis process [22, 44]. In our study, RNAseq analysis revealed that the expression levels of accA, accB, accC, and accD genes were high in the growth phase and then decreased in the stationary phase; however, their transcripts levels were still high in the PHAs production phase, suggesting that the regulation of all four acetyl-CoA carboxylase genes depends on the phase of growth, and that these genes may influence mcl-PHAs concentration. The Pseudomonas putida cells growing at a slower rate on oleic acid (the biomass value reached from 0.87 to 1.4 g/L) synthesized 2.3-times less mcl-PHAs than those growing on sodium gluconate. In both cultures, the level of accABCD-specific mRNA decreased as the bacteria entered the stationary phase. The Acc cluster has been demonstrated to regulate growth rate in Bacillus subtilis and E. coli [23], in which the accBC genes behave analogously to those genes in the Pseudomonas putida KT2440 in our study. In addition, overexpression of Acc (encoding E. coli ACC) has been reported to improve the free fatty acids titer to 0.81 g/L in a batch fermentation [27], indicating that these proteins play an important role in the fatty acids de novo synthesis pathway. Our results suggest that the genes coding for acetyl-CoA carboxylase could coordinate bacterial growth and mcl-PHAs biosynthesis. It could be hypothesized that overexpressing of the genes coding for acetyl-CoA carboxylase may increase the rate of polyhydroxyalkanoates biosynthesis in P. putida KT2440.

Furthermore, the RNAseq revealed that genes involved in the β-oxidation pathway were expressed not only during cultivation on oleic acid but also on sodium gluconate, as shown in Fig. 6. The expression levels of these genes on both substrates were similar. A previous study on Ralstonia eutropha H16 also suggested that the fatty acid β-oxidation pathway was functional in the presence of a non-related carbon source [44]. Fatty acid synthesis may stop when a certain chain length is reached, after which acyl-ACP, which can be converted to acyl-CoA via the β-oxidation pathway, is used for formation of membrane lipids [24]. We predict that FadD (an acyl-CoA synthetase) activated free fatty acids released from membrane lipids into acyl-CoA, and then, they were degraded by β-oxidation pathway.

Previously, it had been reported that the Entner–Doudoroff (ED) pathway seems to be essential for Pseudomonas to metabolize glucose or gluconate [12]. External gluconate can be converted to 6-phosphogluconate and then either decarboxylated to pentose-phosphate, or metabolized to pyruvate and glyceraldehyde 3-phosphate via the ED route. The latter pathway involves two genes: edd (PP_1010) and eda (PP_1021), which encode gluconate 6-P dehydrogenase and 2-keto-3-deoxygluconate-6-P aldolase, respectively. Our results confirm that the edd and eda genes are also active when Pseudomonas putida KT2440 is cultivated on oleic acid. This finding suggests that the ED pathway is functional during mcl-PHAs production and plays a role when fatty acids are used as the only carbon source. This leads us to suggest that the ED pathway may play an important role in the physiology of P. putida KT2440 under environmental stress caused by nitrogen limitation. RNAseq analysis confirmed that the expression level of edd and eda genes at 24 h of the cultivations was higher with sodium gluconate as compared with oleic acid. However, in the stationary growth phase, the eda transcripts were higher when bacteria grown on oleic acid than on gluconate. It is worth noting that the rate of nitrogen consumption was much slower with oleic acid than with gluconate. Furthermore, the ED route may be essential in energy metabolism to provide an appropriate level of redox cofactors in balancing cellular reducing equivalents such as NADH/NADPH. The active ED pathway is not only necessary for the metabolizing of carbon sources but also to fulfilling the bacterial demands for NADPH [8, 37]. The more NADPH, the higher confactor availability [3], leading to an improvement of mcl-PHA synthesis rate. Furthermore, ED pathway works in combination with pentose-phosphate pathway (PP pathway) to synthesize pyruvate and acetyl-CoA. Previously, it was proven that the overexpression of PP pathway’s genes could not increase the PHAs productivity in P. putida KT2440 growing on glucose [5]. Nevertheless, we strongly point out that the genes of PP and ED pathways could be potential molecular targets affecting the cellular mcl-PHA biosynthesis. Moreover, the genes encoding the multicomponent acetoin dehydrogenase enzyme complex (AcoABC and PP_0556) were significantly up-regulated only on sodium gluconate. They catalyze the oxidative decarboxylation of pyruvate with the formation of acetyl-CoA, CO2, and NADH (H +). Based on our results, we hypothesize that the significant increase in aco transcripts had a positive effect on the efficiency of mcl-PHAs synthesis by increasing the pool of cellular acetyl-CoA and NADPH, which are used in fatty acid de novo synthesis during the phase of mcl-PHAs accumulation. The ratios of reducing equivalents are essential for PHAs biosynthesis in bacteria [43]. The overexpression of pyruvate dehydrogenase subunits in P. putida KT2440 grown on glucose, postulating that it is an important step in supplying NADH, and in a consequence, in maximizing mcl-PHAs production [14].

Aside from genes related to metabolism, a number of transporters were differentially regulated during mcl-PHAs synthesis. All of these genes were found to be down-regulated on sodium gluconate, and up-regulated on oleic acid. Although the expression of these genes was higher in the exponential growth phase than in the stationary phase, the level of expression was sufficient for biopolymer production. Nitrogen limitation induced the expression of an LysE family transporter (PP_2388). Its up-regulation in the bacterial cells growing on oleic acid may have supported the survival of these bacteria under stressful conditions. Members of the LysE superfamily have been reported to be involved in ionic homeostasis, protection from excessive metabolite concentrations, cell envelope assembly, and transmembrane electron flow [47]. The Major Facilitator Superfamily Transporter (MFS), which we found to have a higher expression in the exponential phase on sodium gluconate, also seems to play a role in mcl-PHAs synthesis. This is considered to be one of the largest classes of secondary active carriers, which allow the selective transport of a vast range of diverse substrates across the membrane [26].

Global transcriptomics revealed that, during cultivation on sodium gluconate, two regulatory genes (ntrC and PP_2093) were also differentially expressed in the transcriptome of P. putida KT2440, whereas during cultivation on oleic acid, only PP_2093 was observed to be significantly up-regulated. NtrC is a nitrogen-mediated regulator that controls a number of operons involved in the uptake and/or assimilation of alternative nitrogen sources when preferred nitrogen compound are scarce [17, 18]. In addition, NasT regulatory system (PP_2093) has been proposed to induce the nitrate/nitrite assimilatory pathway (generally nas genes), as it is widely distributed in bacteria that can assimilate NO3−/NO2− as their sole source of nitrogen for growth when ammonium is limited [30]. The expression of a cytoplasmic assimilatory NO3−/NO2− reductase system causes NO3− to be converted to NO2− and then to NH4+ [16]. After that, the ammonium is incorporated into glutamate and glutamine which donate nitrogen for biosynthetic cellular metabolism. Under the nitrogen-deficient growth conditions in our study, we postulate that the bulk of L-glutamate was formed by the concerted action of NH4-dependent glutamine synthetase and the glutamine: 2- oxoglutarate amidotransferase (also known as glutamate synthase) in the glutamine synthetase/glutamine:2-oxoglutarate amidotransferase cycle [31]. In our study, the expression of PP_2093 gene, encoding two-component system response regulator NasT, seems to be highest at the beginning of NH4 deficiency in the culture medium. This allowed the bacterial cells to respond immediately to changes in ammonium concentrations. In cultivation on sodium gluconate, nasT was overexpressed at 24 h, when NH4+ was depleted, whereas, on oleic acid, its expression level was lower at that time of the process, because NH4+ was not depleted until the end of cultivation.

In conclusion, a global transcriptomic approach during mcl-PHAs synthesis shows that the environmental stress leads to significant changes in the pattern of gene expression of the Pseudomonas putida KT2440 cells. The results confirm that the biopolymers concentration affects not only PHA synthesis-related genes but also the genes involved in crucial pathways giving the precursors for its biosynthesis. Surprisingly, our results revealed that phaG gene could be associated with the mcl-PHAs synthesis process not only on sodium gluconate but also on oleic acid. A comparison of transcriptomes also revealed that the genes involved in the ED pathway and those coding for acetyl-CoA carboxylase affect biopolymers accumulation. According to the transcriptomic data, several genes related to β-oxidation pathway were active both in growth and PHAs production phase even when Pseudomonas cells were cultivated on sodium gluconate. Furthermore, the expression of genes responsible for intracellular energy supply was modulated to fulfill the bacterial demands for redox cofactors in balancing cellular reducing equivalents. The results indicate that the above-mentioned genes could be possible targets in improving the mcl-PHAs production process. Current knowledge of regulatory machinery governing mcl-PHAs synthesis in Pseudomonas putida strains is limited. An understanding of the regulatory mechanisms can be achieved with the help of systems biology and functional proteomics.

References

Anders S, Huber W (2010) Differential expression analysis for sequence count data. Genome Biol 11:R106

Anjum A, Zuber M, Zia KM, Noreen A, Anjum MN, Tabasum S (2016) Microbial production of polyhydroxyalkanoates (PHAs) and its copolymers: a review of recent advancements. Int J Biol Macromol 89:161–174

Beckers V, Poblete-Castro I, Tomasch J, Wittmann C (2016) Integrated analysis of gene expression and metabolic fluxes in PHA-producing Pseudomonas putida grown on glycerol. Microb Cell Fact 15:73–89

Belda E, van Heck RG, José Lopez-Sanchez M, Cruveiller S, Barbe V, Fraser C, Klenk HP, Petersen J, Morgat A, Nikel PI, Vallenet D, Rouy Z, Sekowska A, Martins Dos Santos VA, de Lorenzo V, Danchin A, Médigue C (2016) The revisited genome of Pseudomonas putida KT2440 enlightens its value as a robust metabolic chassis. Environ Microbiol 18:3403–3424

Borrero-de Acuña JM, Bielecka A, Häussler S, Schobert M, Jahn M, Wittmann C, Jahn D, Poblete-Castro I (2014) Production of medium chain length polyhydroxyalkanoate in metabolic flux optimized Pseudomonas putida. Microb Cell Fact 13:88

Brigham CJ, Sinskey AJ (2012) Applications of polyhydroxyalkanoates in the medical industry. Int J Biotechnol Wellness Ind 1:53–60

Bugnicourt E, Cinelli P, Lazzeri A, Alvarez V (2014) Polyhydroxyalkanoate (PHA): review of synthesis, characteristics, processing and potential applications in packaging. eXPRESS Polym Lett 8:791–808

Chavarría M, Nikel PI, Pérez-Pantoja D, de Lorenzo V (2013) The Entner–Doudoroff pathway empowers Pseudomonas putida KT2440 with a high tolerance to oxidative stress. Environ Microbiol 15:1772–1785

Ciesielski S, Mozejko J, Przybylek G (2010) The influence of nitrogen limitation on mcl-PHA synthesis by two newly isolated strains of Pseudomonas sp. J Ind Microbiol Biotechnol 37:511–520

Ciesielski S, Możejko J, Pisutpaisal N (2015) Plant oils as promising substrates for polyhydroxyalkanoates production. J Clean Prod 106:408–421

Cronan JE, Waldrop GL (2002) Multi-subunit acetyl-CoA carboxylases. Prog Lipid Res 41:407–435

del Castillo T, Ramos JL, Rodríguez-Herva JJ, Fuhrer T, Sauer U, Duque E (2007) Convergent Peripheral pathways catalyze initial glucose catabolism in Pseudomonas putida: genomic and flux analysis. J Bacteriol 189:5142–5152

Fonseca P, de la Peña F, Prieto MA (2014) A role for the regulator PsrA in the polyhydroxyalkanoate metabolism of Pseudomonas putida KT2440. Int J Biol Macromol 71:14–20

Fu J, Sharma P, Spicer V, Krokhin OV, Zhang X, Fristensky B, Cicek N, Sparling R, Levin DB (2015) Quantitative ‘omics analyses of medium chain length polyhydroxyalkanaote metabolism in Pseudomonas putida LS46 cultured with waste glycerol and waste fatty acids. PLoS One 10:e0142322

Galán B, Dinjaski N, Maestro B, de Eugenio LI, Escapa IF, Sanz JM, García JL, Prieto MA (2011) Nucleoid-associated PhaF phasin drives intracellular location and segregation of polyhydroxyalkanoate granules in Pseudomonas putida KT2442. Mol Microbiol 79:402–418

Gates AJ, Luque-Almagro VM, Goddard AD, Ferguson SJ, Roldán MD, Richardson DJ (2011) A composite biochemical system for bacterial nitrate and nitrite assimilation as exemplified by Paracoccus denitrificans. Biochem J 435:743–753

Hervás AB, Canosa I, Santero E (2008) Transcriptome analysis of Pseudomonas putida in response to nitrogen availability. J Bacteriol 190:416–420

Hervás AB, Canosa I, Santero E (2010) Regulation of glutamate dehydrogenase expression in Pseudomonas putida results from its direct repression by NtrC under nitrogen-limiting conditions. Mol Microbiol 78:305–319

Hoffmann N, Rehm BHA (2004) Regulation of polyhydroxyalkanoate biosynthesis in Pseudomonas putida and Pseudomonas aeruginosa. FEMS Microbiol Lett 237:1–7

Hoffmann N, Rehm BHA (2005) Nitrogen-dependent regulation of medium-chain length polyhydroxyalkanoate biosynthesis genes in pseudomonads. Biotechnol Lett 27:279–282

Hoffmann N, Steinbüchel A, Rehm BHA (2000) The Pseudomonas aeruginosa phaG gene product is involved in the synthesis of polyhydroxyalkanoic acid consisting of medium-chain-length constituents from non-related carbon sources. FEMS Microbiol Lett 184:253–259

Huijberts GNM, Eggink G, De Waard P, Huisman GW, Witholt B (1992) Pseudomonas putida KT2442 cultivated on glucose accumulates poly(3-hydroxyalkanoates) consisting of saturated and unsaturated monomers. Appl Environ Microbiol 58:536–544

James ES, Cronan JE (2004) Expression of two Escherichia coli acetyl-CoA carboxylase subunits is autoregulated. J Biol Chem 279:2520–2527

Janßen HJ, Steinbüchel A (2014) Fatty acid synthesis in Escherichia coli and its applications towards the production of fatty acid based biofuels. Biotechnol Biofuels 7:7

Klinke S, De Roo G, Witholt B, Kessler B (2000) Role of phaD in accumulation of medium-chain-length poly(3-hydroxyalkanoates) in Pseudomonas oleovorans. Appl Environ Microbiol 66:3705–3710

Lee J, Sands ZA, Biggin PC (2016) A numbering system for MFS transporter proteins. Front Mol Biosci 3:21

Lennen RM, Braden DJ, West RA, Dumesic JA, Pfleger BF (2010) A process for microbial hydrocarbon synthesis: overproduction of fatty acids in Escherichia coli and catalytic conversion to alkanes. Biotechnol Bioeng 106:193–202

López NI, Pettinari MJ, Nikel PI, Méndez BS (2015) Polyhydroxyalkanoates: much more than biodegradable plastics. Adv Appl Microbiol 93:73–106

Luengo JM, García B, Sandoval A, Naharro G, Olivera ER (2003) Bioplastics from microorganisms. Curr Opin Microbiol 6:251–260

Luque-Almagro VM, Lyall VJ, Ferguson SJ, Roldán MD, Richardson DJ, Gates AJ (2013) Nitrogen oxyanion-dependent dissociation of a two-component complex that regulates bacterial nitrate assimilation. J Biol Chem 288:29692–29702

Merrick MJ, Edwards RA (1995) Nitrogen control in bacteria. Microbiol Rev 59:604–622

Mortazavi A, Williams BA, McCue K, Schaeffer L, Wold B (2008) Mapping and quantifying mammalian transcriptomes by RNA-Seq. Nat Methods 5:621–628

Mozejko J, Ciesielski S (2014) Pulsed feeding strategy is more favorable to medium-chain-length polyhydroxyalkanoates production from waste rapeseed oil. Biotechnol Prog 30:1243–1246

Mozejko J, Przybylek G, Ciesielski S (2011) Waste rapeseed oil as a substrate for medium-chain-length polyhydroxyalkanoates production. Eur J Lipid Sci Technol 113:1550–1557

Mozejko J, Wilke A, Przybyłek G, Ciesielski S (2012) Mcl-PHAs produced by Pseudomonas sp. Gl01 using fed-batch cultivation with waste rapeseed oil as carbon source. J Microbiol Biotechnol 22:371–377

Mozejko-Ciesielska J, Dabrowska D, Szalewska-Palasz A, Ciesielski S (2017) Medium-chain-length polyhydroxyalkanoates synthesis by Pseudomonas putida KT2440 relA/spoT mutant: bioprocess characterization and transcriptome analysis. AMB Express 7:92

Nikel PI, Kim J, de Lorenzo V (2014) Metabolic and regulatory rearrangements underlying glycerol metabolism in Pseudomonas putida KT2440. Environ Microbiol 16:239–254

Poblete-Castro I, Binger D, Oehlert R, Rohde M (2014) Comparison of mcl-poly(3-hydroxyalkanoates) synthesis by different Pseudomonas putida strains from crude glycerol: citrate accumulates at high titer under PHA-producing conditions. BMC Biotechnol 14:962

Poblete-Castro I, Escapa IF, Jäger C, Puchalka J, Chi Lam C, Schomburg D, Prieto M, Martins dos Santos VA (2012) The metabolic response of P. putida KT2442 producing high levels of polyhydroxyalkanoate under single- and multiple-nutrient-limited growth: highlights from a multi-level omics approach. Microb Cell Fact 11:34–55

Prieto A, Escapa IF, Martínez V, Dinjaski N, Herencias C, de la Peña F, Tarazona N, Revelles O (2016) A holistic view of polyhydroxyalkanoate metabolism in Pseudomonas putida. Environ Microbiol 18:341–357

Prieto MA, Hler BB, Jung K, Witholt B, Kessler B (1999) PhaF, a Polyhydroxyalkanoate-granule-associated protein of Pseudomonas oleovorans GPo1 involved in the regulatory expression system for pha genes. J Bacteriol 181:858–868

Rehm BH, Mitsky TA, Steinbüchel A (2001) Role of fatty acid de novo biosynthesis in polyhydroxyalkanoic acid (PHA) and rhamnolipid synthesis by pseudomonads: establishment of the transacylase (PhaG)-mediated pathway for PHA biosynthesis in Escherichia coli. Appl Environ Microbiol 67:3102–3109

Ren Q, de Roo G, Witholt B, Zinn M, Thöny-Meyer L (2010) Influence of growth stage on activities of polyhydroxyalkanoate (PHA) polymerase and PHA depolymerase in Pseudomonas putida U. BMC Microbiol 10:254

Shimizu R, Chou K, Orita I, Suzuki Y, Nakamura S, Fukui T (2013) Detection of phase-dependent transcriptomic changes and Rubisco-mediated CO2 fixation into poly (3-hydroxybutyrate) under heterotrophic condition in Ralstonia eutropha H16 based on RNA-seq and gene deletion analyses. BMC Microbiol 13:169

Steinbüchel A, Valentin HE (1995) Diversity of bacterial polyhydroxyalkanoic acids. FEMS Microbiol Lett 128:219–228

Tan GYA, Chen CL, Li L, Ge L, Wang L, Razaad IMN, Li Y, Zhao L, Mo Y, Wang JY (2014) Start a research on biopolymer polyhydroxyalkanoate (PHA): a review. Polymers 6:706–754

Tsu BV, Saier MH (2015) The LysE superfamily of transport proteins involved in cell physiology and pathogenesis. PLoS One 10:e0137184

Acknowledgements

This work was supported by the National Science Centre (Poland) under Grant number 2012/05/B/NZ1/00011.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary material S1.

Significantly differentially expressed genes of Pseudomonas putida KT2440 grown on sodium gluconate. (PDF 115 kb)

Supplementary material S2.

Significantly differentially expressed genes of Pseudomonas putida KT2440 grown on oleic acid. (PDF 112 kb)

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Mozejko-Ciesielska, J., Pokoj, T. & Ciesielski, S. Transcriptome remodeling of Pseudomonas putida KT2440 during mcl-PHAs synthesis: effect of different carbon sources and response to nitrogen stress. J Ind Microbiol Biotechnol 45, 433–446 (2018). https://doi.org/10.1007/s10295-018-2042-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-018-2042-4