Abstract

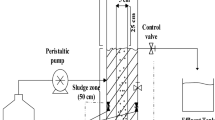

Economic production of biodegradable plastics is a challenge particularly because of high substrate and energy cost inputs for its production. Research efforts are being directed towards innovations to minimize both of the above costs to economize polyhydroxybutyrate (PHB) production. A novel airlift reactor (ALR) with outer aeration and internal settling was utilized in this investigation. Although it featured no power consumption for agitation, it facilitated increased oxygen transfer rate and better cell retention than stirred tank reactor (STR), thereby resulting in enhanced PHB productivity. ALR with in situ cell retention demonstrated a significant improvement in biomass concentration and biopolymer accumulation. The total PHB production rate, specific biomass, and product yield in the ALR were observed to be 0.84 g/h, 0.43 g/g, and 0.32 g/g, respectively. The studies revealed that the volumetric oxygen mass transfer rate and mixing time for ALR were 0.016 s−1 and 3.73 s, respectively, at 2.0 vvm as compared with corresponding values of 0.005 s−1 and 4.95 s, respectively, in STR. This demonstrated that ALR has better oxygen mass transfer and mixing efficiency than STR. Hence, ALR with cell retention would serve as a better bioreactor design for economic biopolymer production than STR, particularly due to its lower cost of operation and simplicity along with its enhanced oxygen and heat transfer rates.

Similar content being viewed by others

References

Alam Z, Muhd NH, Razali F (2005) Scale-up of stirred and aerated bioengineering bioreactor based on constant mass transfer coefficient. J Teknologi 43:95–110

Anderson AJ, Dawes EA (1990) Occurrence, metabolism, metabolic role, and industrial uses of bacterial polyhydroxyalkanoates. Microbiol Rev 54:450–472

Barham PJ, Barker P, Organ SJ (1992) Physical properties of poly (hydroxybutyrate) and copolymers of hydroxybutyrate and hydroxyvalerate. FEMS Microbiol Lett 103:289–298

Birch JR, Lambert K, Thompson PW, Kenney AC, Wood LA (1987) Antibody production with airlift fermentors. In: Lydersen BK (ed) Large scale cell culture technology. Hansen, New York, pp 1–20

Blakebrough N, Sambamurthy K (1966) Mass transfer and mixing rates in fermentation vessels. Biotechnol Bioeng 8:25–42

Braunegg G, Bogensberger B (1985) Zur Kinetik des Wachstums und der Speicherung von Poly-D (-) - 3-hydroxybuttersäure bei Alcaligenes latus. Acta Biotechnol 5:339–345

Chisti MY, Moo-Young M (1987) Airlift reactors: characteristics, applications and design considerations. Chem Eng Comm 60:195–242

Chisti Y, Moo-young M (1988) Prediction of liquid circulation velocity in airlift reactors with biological media. J Chem Tech Biotechnol 42:211–219

Choi J, Lee SY (1999) Factors affecting economics of polyhydroxyalkanoate production by bacterial fermentation. Appl Microbiol Biotechnol 51:13–21

Dominguez A, Couto RS, Sanroman A (2001) Amelioration of ligninolytic enzyme production by Phanerochaete chrysosporium in airlift bioreactor. Biotechnol Lett 23:451–455

Fontana RC, Polidoro TA, da Silveira MM (2009) Comparison of stirred tank and air lift bioreactor in the production of polygalacturonase by Aspergillus oryzae. Bioresour Technol 100:4493–4498

Gavrilescu M, Tudose RZ (1998) Concentric-tube airlift bioreactors. Part 1: effects of geometry on gas hold-up. Bioprocess Eng 19(1):37–44

Gupta K, Mishra PK, Srivastava P (2009) Enhanced continuous production of lovastatin using pellets and siran supported growth of Aspergillus terreus in an airlift reactor. Biotechnol Bioprocess Eng 14:207–212

Hängii UJ (1990) Pilot scale production of PHB with Alcaligenes latus. In: Dawes EA (ed) Novel biodegradable microbial polymers. Kluwer, Dordrecht, pp 65–70

Horwitz W (1980) Official methods of analysis of the association of official analytical chemist. AOAC Methods, Washington

Lamare S, Legoy M (1993) Biocatalysis in gas phase. Trends Biotechnol 11:413–419

Lee SY (1996) Plastic bacteria? Progress and prospects for polyhydroxyalkanoates production in bacteria. Trends Biotechnol 14:431–438

Loo CY, Sudesh K (2007) Polyhydroxyalkanoates: bio-based microbial plastics and their properties. Malaysian Polym J 2:31–57

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Plackett RL, Burman JP (1946) The design of optimum multifactorial experiments. Biometrica 33:305–325

Riis V, Mai W (1988) Gas chromatographic determination of poly β-hydroxybutyric acid in microbial biomass after hydrochloric propanolysis. J Chromat 445:285–289

Saravanan P, Pakshirajan K, Saha P (2008) Performance of batch stirred tank bioreactor and internal loop airlift bioreactor in degrading phenol using Pseudomonas spp.: a comparative study. J Environ Protect Sci 2:81–86

Tavares LZ, da Silva ES, da Cruz Pradella JG (2004) Production of poly(3-hydroxybutyrate) in an airlift bioreactor by Ralstonia eutropha. Biochem Eng 18:21–31

Wang F, Lee SY (1997) Poly (3-hydroxybutyrate) production with high productivity and high polymer content by a fed-batch culture of Alcaligenes latus under nitrogen limitation. Appl Environ Microbiol 63:3703–3706

Wang SJ, Zhong JJ (1996) A novel centrifugal impeller bioreactor. II. Oxygen transfer and power consumption. Biotechnol Bioeng 51:520–527

Yezza A, Halasz A, Levadoux W, Hawari J (2007) Production of poly-β-hydroxybutyrate (PHB) by Alcaligenes latus from maple sap. Appl Microbiol Biotechnol 77:269–274

Yu PHF, Chua H, Huang AL, Lo WH, Ho KP (1999) Transformation of industrial food wastes into polyhydroxyalkanoates. Water Sci Technol 40:365–370

Acknowledgments

The senior research fellowship (SRF) awarded by The Department of Biotechnology (DBT), Govt. of India, New Delhi for project execution is gratefully acknowledged by one of the authors (G.G.).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gahlawat, G., Sengupta, B. & Srivastava, A.K. Enhanced production of poly(3-hydroxybutyrate) in a novel airlift reactor with in situ cell retention using Azohydromonas australica . J Ind Microbiol Biotechnol 39, 1377–1384 (2012). https://doi.org/10.1007/s10295-012-1138-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-012-1138-5